In the field of mining crushing, double-roll crusher and cone crusher are both common medium and fine crushing equipment, but their working principles, applicable scenarios and cost-effectiveness are very different. This article will compare the 10 core differences between the two types of equipment in detail, and give specific selection suggestions to help you make the best choice based on material characteristics, production needs and budget.

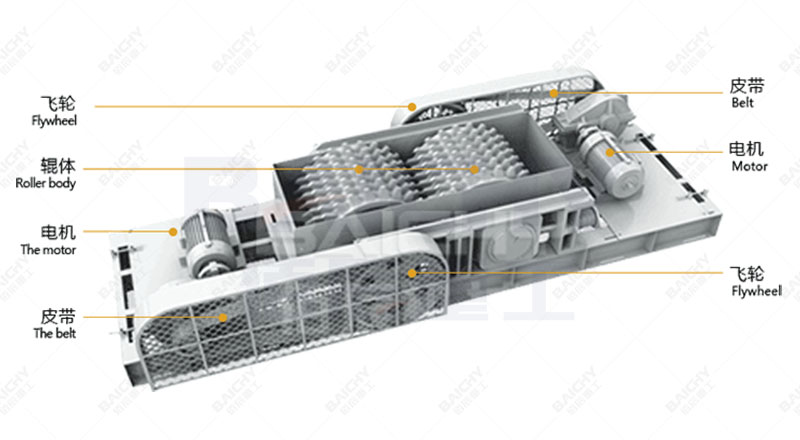

1. Working principle and structure of double-roll crusher

Crushing principle:

The material is squeezed through two rollers (fixed roller and adjustable roller) rotating in opposite directions, and the material is brought into the crushing chamber by friction to achieve the effect of squeezing, splitting and crushing.

• Key components: roller (high manganese steel/alloy steel roller skin), adjustment device (hydraulic or spring), drive motor, frame.

• Discharge control: Adjusting the gap between the two rollers (0.2-30mm) can accurately control the particle size of the finished product.

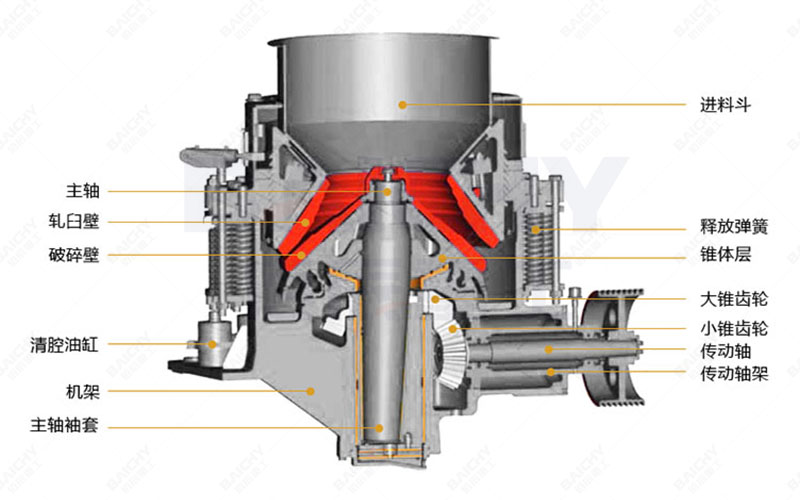

2. Working principle and structure of cone crusher

Crushing principle:

The moving cone performs eccentric pendulum motion (swing frequency 200-800 times/minute), and the material is subjected to multiple extrusion, bending and shearing between the moving cone and the fixed cone.

• Key components: crushing chamber type, spindle system, hydraulic system

• Discharge control: The gap between the mortar walls (0-30mm) can accurately control the particle size of the finished product.

3. Comparison of applicable material hardnes

| Equipment type | Recommended material hardness range | Typical applicable materials |

| Double-roll crusher | ≤160MPa (Mohs hardness ≤6) | Coal, limestone, gypsum, bauxite |

| Cone crusher | ≤350MPa (Mohs hardness ≤8) | Granite, iron ore, copper ore, quartz |

Case: The Mexican iron ore project first uses a jaw crusher for coarse crushing and then a cone crusher for medium crushing, while the limestone sand making line often uses a double-roll crusher for fine crushing.

4. Comparison of production capacity and energy consumption (taking the same power 75kW equipment as an example)

| Parameters | Double-roll crusher | Cone crusher |

| Processing capacity | |30-100t/h | 100-300t/h |

| Power consumption | 0.8-1.2kWh/t | 0.5-0.9kWh/t |

| Maximum feed size | ≤50mm | ≤200mm |

The crushing performance of cone crusher is 3 times that of double-roll crusher, but double-roll crusher has lower energy consumption when fine crushing (≤10mm).

5. Comparison of discharge particle size control

• Double-roll crusher:

Precise control by adjusting the roller gap (adjustable from 0.2 to 30 mm)

Better fine crushing effect, low over-crushing rate (<10%)

• Cone crusher:

Change particle size by replacing liner or adjusting eccentricity

Generally, the discharge range is 3-60 mm, and there is more powder when finely crushed

6. FAQ

Q: Which type of limestone sand making line should be selected for an output of 50 tons per hour?

→ Double-roll crusher is recommended (discharge is more uniform and maintenance is simple)

Q: Can double-roll crusher be used to crush iron ore?

→ Not recommended, cone crusher + wear-resistant liner should be selected for high-hardness ore

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)