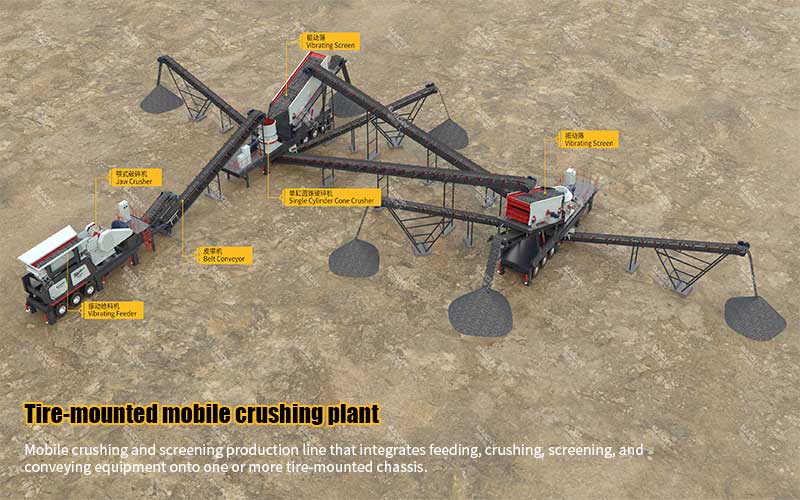

Tire-mounted mobile crushing plant

In the rapidly developing Vietnamese market, driven by infrastructure development and urbanization, the demand for efficient and environmentally friendly aggregate materials is constantly growing. When Vietnamese clients seek a 250 tph mobile crushing plant, it usually signifies the commencement of a medium-to-large-scale quarrying operation, a construction waste recycling project, or a major infrastructure construction project. As a mining crushing equipment manufacturer with 20 years of experience, we deeply understand that this is not just about purchasing a piece of equipment, but a comprehensive consideration of project mobility, output quality, long-term operating costs, and return on investment.

Core Needs Analysis: Why a 250 TPH Mobile Crushing Plant?

A processing capacity of 250 tons per hour is one of the most cost-effective and adaptable options currently available in the Vietnamese market. It perfectly balances investment scale and output efficiency, meeting the continuous material supply needs of large projects while avoiding capital waste due to excessive equipment redundancy. Clients' core needs typically focus on:

• High mobility: The ability to quickly move between different construction sites, close to the material source or construction site, significantly reducing material transportation costs.

• Integrated unit: Feeding, crushing, screening, and conveying systems are integrated into one unit, reducing infrastructure construction and enabling rapid commissioning.

• Adaptability to complex raw materials: Capable of processing hard rocks such as river pebbles, granite, and limestone, as well as recycled materials such as construction waste.

• Environmental protection and intelligence: Meeting increasingly stringent local environmental requirements and reducing operating difficulties and labor costs through intelligent control systems.

Our Solution Overview: A Mobile Crushing Powerhouse Forged by 20 Years of Experience

Our 250 TPH mobile crushing plant, specifically designed for the working conditions of Vietnam and Southeast Asia, is not simply a standard product, but a deeply customized solution based on twenty years of project experience. This series typically adopts a combination of mobile jaw crusher + mobile cone crusher/impact crusher or a single-unit multi-functional mobile crusher to ensure the best balance in crushing efficiency, product particle shape, and equipment wear resistance.

Our Core Advantages: Why Choose Us?

1. Twenty Years of Technical Expertise: We have been deeply involved in the crushing and screening field for two decades, with a profound understanding of the core components of the equipment – rotors, cavity types, and wear-resistant materials – ensuring the robust and durable heart of the equipment.

2. All-Condition Adaptability Design: Vietnam's high temperature, high humidity, and rainy climate, as well as perse material characteristics, we have implemented special enhancements in the electrical system, anti-corrosion processes, and heat dissipation design, resulting in higher equipment reliability.

3. Intelligent Control System: Equipped with an advanced PLC intelligent control system and remote monitoring platform, it enables fault diagnosis, production capacity adjustment, and wear part life prediction, allowing customers to monitor the entire production process from their mobile devices.

4. Excellent After-Sales Service Network: We have a resident service team and spare parts warehouse in Vietnam, providing full-cycle services from installation and commissioning, operation training, to regular inspections and rapid response, ensuring peace of mind for our customers.

5. High Cost-Effectiveness and Return on Investment: Thanks to our mature supply chain and large-scale production, we can provide top-tier configurations while ensuring more competitive prices, helping customers recover their investment faster.

Successful Case Study: Dong Thap Province Granite Crushing Project, Vietnam

Successful Case Study: Dong Thap Province Granite Crushing Project, Vietnam

• Customer Challenge: The project is located in a riverside area with limited space. The raw material is high-hardness granite, and the required final products are three types of high-quality aggregates: 0-5mm, 5-10mm, and 10-20mm, for local highway construction.

• Solution: We provided a combination of a tire-mounted mobile jaw crusher station + tire-mounted mobile cone crusher station. The jaw crusher performs coarse crushing, and the cone crusher performs medium and fine crushing, achieving layered crushing to ensure excellent product particle shape. The entire set of equipment does not require piling and was installed and commissioned within one week.

• Project Results: The actual output is stable at 260-270 TPH, exceeding expectations. The product has a high cubic content and is highly favored by concrete mixing plants. The low failure rate of the equipment and localized service ensured uninterrupted production for 8 consecutive months, and the customer is very satisfied with the return on investment.

Related Equipment Recommendations

In addition to the standard 250 TPH solution, we also offer a variety of options based on different customer budgets and raw materials:

• Economical and Efficient Type: Uses a high-output single-stage heavy-duty impact mobile crushing station, suitable for medium-hardness materials, resulting in lower investment costs.

• Top-Tier Configuration Type: Equipped with an intelligent cone crusher with hydraulic adjustment and automatic cavity cleaning, used for ultra-hard materials and extreme working conditions, aiming for extremely low cost per ton. • Dedicated for Construction Waste Processing: Featuring enhanced feeding and iron removal systems, and equipped with a light material separator, this is the ideal choice for urban construction resource utilization projects.

Frequently Asked Questions (FAQ)

Q1: How long does it take from shipment to on-site installation and commissioning in Vietnam?

A1: Typically, after confirming the plan and payment, shipment can be completed within 60-75 days. After sea freight arrives at major ports in Vietnam, our engineers will provide full guidance for installation, and commissioning can be completed in approximately 7-10 days.

Q2: What is the wear resistance of the equipment's wear parts (such as blow bars and side plates)? Is the supply timely?

A2: We use core wear parts cast from new composite materials, which have a service life more than 30% longer than ordinary products on the market. We have a spare parts warehouse in Ho Chi Minh City, ensuring that commonly used wear parts can be shipped within 24 hours.

Q3: Can the equipment adapt to the rainy and muddy construction site environment in Vietnam?

A3: Absolutely. Our mobile crushing plant uses a reinforced heavy-duty chassis, and a crawler-type model is available as an option, resulting in low ground pressure and excellent passability. The protection level of key electrical components reaches IP65 or higher, effectively preventing dust and water ingress.

Q4: Do you offer trial runs and factory visits?

A4: We warmly welcome Vietnamese customers to visit our factory in China to witness our manufacturing process and assembly quality firsthand. At the same time, we have a complete trial run base at our headquarters in China, where we can arrange for customers to conduct trial runs with their own materials, letting the real data speak for itself.