Mining equipment in Peru

As a major mining country in South America, Peru's mining industry has always been a pillar of its national economy. In recent years, with the continuous growth in demand for the extraction of metal ores such as copper, gold, and zinc, the need for efficient and reliable crushing equipment has become increasingly urgent.

Cone crushers, with their high efficiency in the secondary and fine crushing stages, have become a key piece of equipment for many Peruvian mining clients to increase production capacity and reduce energy consumption. When searching for cone crushers, Peruvian clients typically focus on the equipment's durability, ability to adapt to high-altitude working conditions, ease of maintenance, and long-term cost-effectiveness. This is precisely where we, as a mining crushing equipment manufacturer with 20 years of professional experience, can provide core value.

| Key Words | Hydraulic cone crusher |

|---|---|

| Product Model | Cone Crusher |

| Feed Size | ≤285mm |

| Motor Power | 160-450kw |

| Capacity | 90-1200 t/h |

| Core Advantages | High efficiency and energy saving, excellent particle shape, flexible adjustment, and simultaneous shaping capabilities. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Company Overview: 20 Years of Professional Experience, Focused on Mining Crushing Solutions

We are a Chinese manufacturer with twenty years of experience in the mining crushing equipment field. For two decades, we have consistently focused on the research, development, production, and supply of a full range of mining crushing and screening equipment, with our core products including various models of high-performance cone crushers. We deeply understand the challenges faced by different mines globally, especially in markets with complex geographical and working conditions like Peru. Our team is not only proficient in equipment manufacturing but also provides clients with one-stop services ranging from selection consultation and solution design to installation guidance and after-sales support, ensuring long-term production efficiency for our clients.

Our Cone Crusher's Core Advantages

Addressing the stringent requirements of international markets such as Peru, our cone crusher products possess the following outstanding advantages:

1. Exceptional Durability and Reliability: Core components such as the moving cone and fixed cone are made of high-strength alloy materials and are optimized in design to withstand the high-intensity, continuous operation of Peruvian mines, significantly reducing unexpected downtime.

2. Excellent Particle Shape Control: The unique lamination crushing principle and cavity design produce final products with excellent particle shape and low needle-like and flaky content, greatly increasing the value of aggregates and meeting the needs of high-end construction and special processes.

3. Intelligent Hydraulic System: Equipped with an advanced hydraulic adjustment and tramp iron protection system, the discharge opening is easily adjustable, and it can automatically release and reset when encountering unbreakable foreign objects, effectively protecting the core components of the equipment and ensuring safety.

4. High Energy Efficiency: The optimized crushing chamber and matched motion parameters result in significantly lower energy consumption compared to traditional equipment at the same production capacity, helping our Peruvian customers effectively control rising operating costs.

The equipment design takes into account environmental factors such as high altitude, dust, and temperature variations, ensuring stable operation under Peru's perse geographical and climatic conditions.

Hydraulic cone crusher at a customer's site

Success Stories: Empowering Global Mines, Including in South America

Our equipment has been exported to over 50 countries and regions worldwide, including several projects in South America. For example, we provided two high-performance multi-cylinder hydraulic cone crushers to a large copper mine project in central Peru for the secondary and tertiary crushing stages. The mine is located at a high altitude, posing a significant challenge to equipment power and heat dissipation. Thanks to the exceptional adaptability and stability of our equipment, the customer increased the qualified rate of the final crushed product by 15%, while reducing maintenance costs by approximately 20%, earning high praise from the client. Similar projects in Chile and Colombia have also verified the high reliability of our cone crushers in the Andes Mountains mining areas.

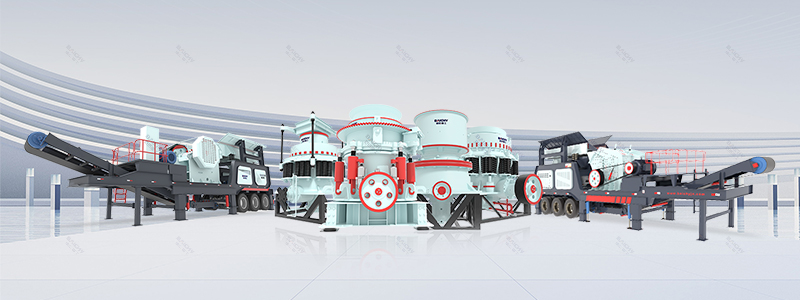

A large collection of cone crushers

Product Series Recommendation

For Peruvian customers with different production capacities and crushing needs, we recommend the following cone crusher series:

HPM Multi-cylinder Hydraulic Cone Crusher: Suitable for secondary and tertiary crushing of hard rock (such as granite and copper ore), ideal for high production capacity and excellent particle shape. Recommended for large-scale mining projects.

Single-cylinder Hydraulic Cone Crusher: Compact structure, easy maintenance, and high cost-effectiveness, suitable for medium-scale production and materials with medium compressive strength.

Fully Hydraulic Cone Crusher: High degree of automation and precise adjustment, an ideal choice for customers pursuing intelligent and refined production.

Our engineers can recommend the most suitable model and provide a detailed solution design based on your specific material characteristics (hardness, humidity, feed size), expected production capacity, and final product requirements.

Frequently Asked Questions (FAQ)

Q1: Can your cone crushers handle common copper and gold ores found in Peru? What is the lifespan of the wear parts?

A1: Absolutely. Our cone crushers are specifically designed for hard rock crushing. The key wear parts are made of special high-manganese steel or composite alloys and reinforced through casting processes. For highly abrasive ores, we can provide customized wear-resistant solutions to ensure a longer service life when crushing common Peruvian ores.

Q2: Is the equipment suitable for high-altitude mining areas in Peru?

A2: Yes, this is one of the key considerations in our design. We have specially optimized the lubrication and cooling systems to ensure that the equipment maintains good heat dissipation and lubrication even in high-altitude areas with low air pressure and thin air, and that the power system can operate stably.

Q3: How is after-sales service and support guaranteed?

A3: We have long-term service partners and spare parts warehouses in South America, enabling us to provide a quick response. We provide detailed installation instruction manuals, remote video support, and can dispatch engineers to provide on-site installation and commissioning guidance. We also guarantee the long-term supply of original spare parts.

Q4: Can you provide testing or site visit opportunities?

A4: You are welcome to visit our factory and testing base in China to witness the equipment testing firsthand. We can also arrange for you to visit some of our successful case studies in South America, depending on the actual situation (subject to customer confidentiality agreements).

Q5: What is the delivery time from order placement to arrival at the Peruvian port?

A5: The delivery time for standard models is usually around 30-45 days, depending on the model configuration and production schedule. We will maintain close communication with you and provide clear logistics tracking information.