Jaw Crushers for Sale | Rock Crusher Machine

In mining, aggregate production, and various rock crushing operations, the jaw crusher is the absolute workhorse for primary crushing, its position being unshakeable. With its robust structure, extremely high reliability, and wide material adaptability, it stands as the steel pioneer on the production line.

As a mining crushing equipment manufacturer with 20 years of experience, we understand that a high-quality jaw crusher is the cornerstone of the entire production system's efficiency, cost-effectiveness, and stability. This article aims to provide an in-depth analysis of the key advantages of the jaw crusher (rock crusher) to help you make informed investment decisions.

| Key Words | Jaw Crusher for Primary Crushing |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | 100-1200mm |

| Motor Power | 30-280kw |

| Capacity | 0-1200 t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

What is a Jaw Crusher?

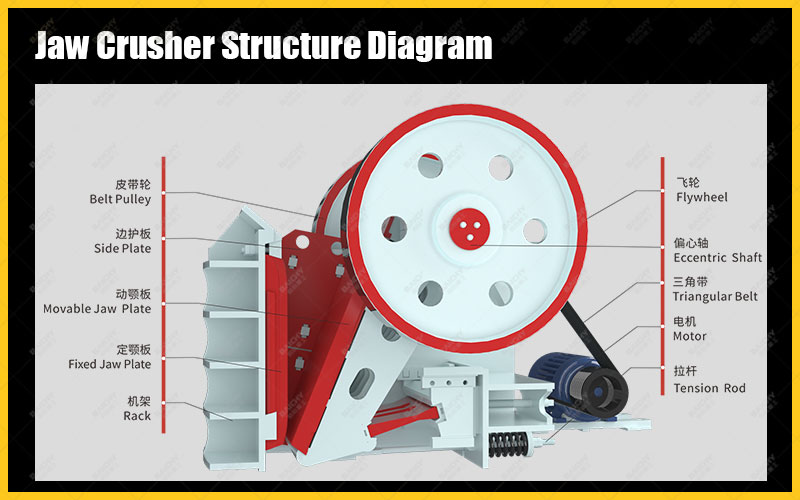

The jaw crusher, commonly known as a tiger's mouth, works by simulating the chewing motion of an animal using two jaw plates, a movable jaw and a fixed jaw, to compress, bend, and split the material, thus achieving rock crushing. It mainly consists of a frame, movable jaw, eccentric shaft, jaw plates, adjustment device, and other core components. Based on the trajectory of the movable jaw, it can be mainly pided into double-toggle and single-toggle types, with the double-toggle type being more widely used due to its simple structure, high efficiency, and uniform product particle size. As the most classic member of the rock crusher family, it is suitable for coarse and medium crushing of various ores and rocks with a compressive strength of no more than 320 MPa.

PE jaw crusher structure diagram

Four Core Advantages Forged by 20 Years of Manufacturing Experience

Based on twenty years of technological accumulation and hundreds of project practices, our jaw crushers possess the following unparalleled advantages:

1. Exceptional Durability and Reliability: Utilizing high-strength steel plate welded frames, heavy-duty eccentric shafts, and large roller bearings, key components are optimized through finite element analysis, ensuring long-term stable operation under heavy load and high-impact harsh working conditions, greatly reducing the risk of unexpected downtime.

2. Superior Crushing Efficiency and Low Energy Consumption: The optimized cavity design results in a deeper crushing chamber and a larger crushing ratio, significantly increasing material throughput. Coupled with precise dynamic design, it achieves higher productivity and a lower power consumption per ton, directly saving operating costs for customers.

3. Convenient Maintenance and Adjustment: The modular design allows for quicker replacement of wear parts (such as jaw plates). The discharge opening uses a wedge or shim adjustment mechanism with hydraulic assistance, making particle size adjustment convenient and precise, greatly simplifying daily maintenance.

4. Wide Material Adaptability: From hard granite and basalt to recycled construction waste, our equipment can handle materials of varying hardness, viscosity, and moisture content, making it a truly multi-functional rock crusher.

Success Stories: Witnessing Our Strength

Case Study 1: A Large Granite Quarry in East China

Challenge: The original equipment had insufficient output, high flake content in the finished product, and extremely rapid jaw plate wear.

Solution: We equipped them with a PE-1200×1500 large deep-cavity jaw crusher.

Results: The hourly output stably reached 800-1000 tons, the finished product particle size was uniform (flake rate reduced by 40%), the service life of the core jaw plates was extended by 1.5 times, and the customer's return on investment was significantly shortened.

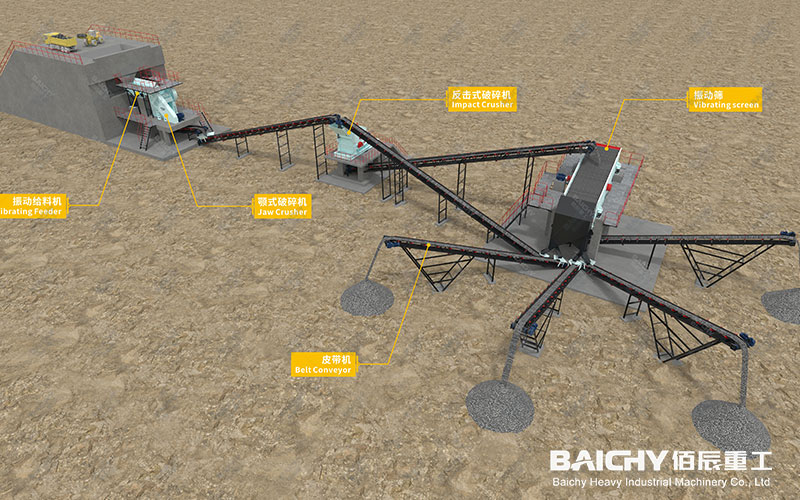

Stationary crushing production line

Case Study 2: A Southeast Asian Iron Ore Crushing Production Line

Challenge: The ore had high hardness and strong abrasiveness, requiring demanding wear resistance and continuous operation from the equipment.

Solution: We provided a jaw crusher with special high-manganese steel jaw plates and a reinforced frame, equipped with an intelligent lubrication system.

Results: The equipment operated continuously for two years without major repairs, the production capacity fully met the requirements, and the wear parts replacement cycle met expectations, receiving high praise from the owner.

Jaw Crushing Plant

Related Product Recommendations

When selecting equipment for your production line, jaw crushers usually need to be matched with subsequent equipment to form an efficient production line. We recommend that you also consider:

Cone Crusher: Used for medium and fine crushing, handling high-hardness materials, and producing good particle shape.

Impact Crusher: Used for medium crushing, suitable for medium and low-hardness materials, producing excellent particle shape, and facilitating shaping.

Vibrating Feeder and Circular Vibrating Screen: These form a complete feeding and screening system, which is crucial for improving overall efficiency. Mobile Crushing Plant: Integrates feeding, crushing, and screening into one unit, offering exceptional flexibility and suitability for multi-site operations.

Frequently Asked Questions (FAQ)

Q1: How to choose the right jaw crusher model?

A: The selection mainly depends on the maximum feed size, hardness of the material to be processed, required processing capacity (tons/hour), and the desired final product particle size. Our engineering team can provide free selection consultation and solution design.

Q2: What is the lifespan of the core wear parts (jaw plates)?

A: The lifespan varies depending on the material hardness, abrasiveness, and equipment operating time. Typically, when processing ordinary granite, high-manganese steel jaw plates can last 6-12 months. We offer jaw plates made of various materials (such as high-chromium cast iron, composite metals) to suit different working conditions.

Q3: Do you provide support for equipment installation and commissioning?

A: Yes. We provide detailed installation foundation drawings, technical documents, and can dispatch experienced engineers to the site to guide installation, commissioning, and operation training, ensuring rapid equipment commissioning.

Q4: What are the specific advantages of your company as a manufacturer?

A: As a professional manufacturer (not a trading company) with 20 years of experience, we control the entire process from R&D, casting, machining to final assembly, ensuring core processes and product quality. This directly translates into more competitive prices, faster spare parts supply, and continuous technical upgrade support.