Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The PF1007 impact crusher has a standard processing capacity of 15-60 t/h (depending on material hardness, feed size, and discharge adjustment). It is a small- to medium-sized crushing machine suitable for the following production scenarios:

• Standalone operation: Suitable for small sand and gravel plants and construction waste recycling stations, with a daily output of approximately 300-500 tons.

• Integral production line: As a secondary crushing unit (such as a jaw crusher + impact crusher combination), it can meet the needs of medium-sized production lines with a capacity of 50-100 tons/hour.

• Higher material hardness results in lower capacity. It is recommended to reduce the feed rate or increase pre-screening.

• Wet and sticky materials (such as those containing soil and rocks) are prone to clogging and require moisture control or the addition of a vibrating feeder.

The PF1007 impact crusher is a cost-effective choice for small to medium-sized crushing lines (15-60 t/h), particularly suitable for processing medium-hardness materials such as limestone and construction waste. With the appropriate configuration of feeding and screening equipment, it can stably meet the daily production demands of 500 tons. For higher production capacity, upgrading the model or connecting multiple units in parallel is recommended.

| Model | PF-1007 |

|---|---|

| Feeder Opening Size(mm) | 450X730 |

| Max. Feeding Size(mm) | 250 |

| Rotor sizeD*L(mm) | Φ1000X700 |

| Motor Power(kw) | 37-55 |

| Capacity(t/h) | 15-60 |

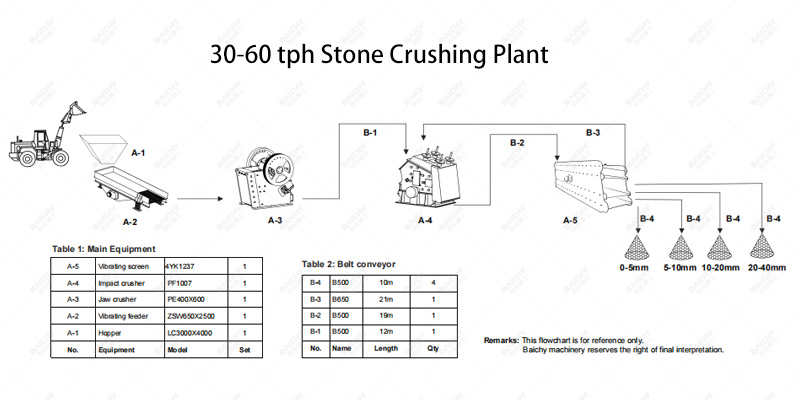

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | LC3000×4000 | 1 |

| 2 | Vibrating feeder | ZSW600x2500 | 1 |

| 3 | Jaw Crusher | PE400x600 | 1 |

| 4 | Impact Crusher | PF1007 | 1 |

| 5 | Vibrating Screen | 4YK1237 | 1 |

| 6 | Belt conveyor | B650 | 1 |

| 7 | Belt conveyor | B500 | 6 |

Limestone is a key raw material in industries such as building materials, cement, and metallurgy, making the stability and economy of its crushing lines crucial. The PF1007 impact crusher, with its high crushing efficiency, low energy consumption, and excellent finished product particle shape, is an ideal choice for limestone crushing lines with a capacity of 30-60 tph.

• Jaw Crusher + Impact Crusher Combination: The PE400×600 jaw crusher handles large limestone lumps, while the PF1007 handles secondary and fine crushing. Overall energy consumption is 15%-20% lower than that of single-stage crushing.

• Excellent Finished Product Shape: The "rock-on-rock" principle of the impact crusher produces cubic limestone particles with less than 10% flake content, surpassing hammer crushing.

• Small and medium-sized sand and gravel aggregate plants: Meets the high demands of ready-mix concrete plants, dry mortar, and other applications requiring high finished product particle shape. • Cement Plant Raw Material Preparation: Crushed limestone can be fed directly into the raw mill system.

Note: If the limestone contains more than 5% mud, a stone washer or pre-screening system should be installed before the impact crusher to prevent sticking.

✔ Small and medium-sized limestone aggregate plants ✔ Cement plant raw material crushing ✔ Construction waste recycling

For customized 30-60tph limestone crushing solutions or to obtain PF1007 technical data, please contact our professional engineers for a one-on-one design!

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!