Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In the fields of sand and gravel aggregate production and mining crushing, choosing an efficient and reliable secondary crushing equipment is crucial. The PF-1010 impact crusher, with its unique crushing principle, stable performance, and excellent finished product shape, is an ideal choice for processing medium-hard materials.

The PF1010 impact crusher utilizes the impact crushing principle. The process is as follows:

• Feed: Material enters the crushing chamber and collides with the hammers on the high-speed rotating rotor.

• Impact Crushing: Material is struck by the hammers and flung at high speed toward the impact plate for further crushing.

• Screening and Discharge: The crushed material is adjusted to a controlled discharge size by adjusting the gap between the impact plate and the rotor. Material that meets the requirements is discharged from the discharge port.

• High crushing ratio, good final product shape (more cubes, less flakes)

• Adjustable discharge size to meet different production needs

• Simple structure, low maintenance

| Model | PF-1010 |

|---|---|

| Feeder Opening Size(mm) | 400X1080 |

| Max. Feeding Size(mm) | 300 |

| Rotor sizeD*L(mm) | Φ1000X1050 |

| Motor Power(kw) | 50-90 |

| Capacity(t/h) | 55-75 |

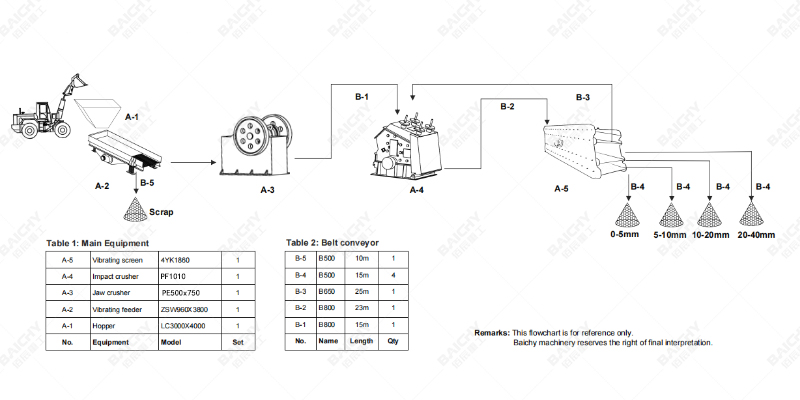

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | LC3000*4000 | 1 |

| 2 | Vibrating feeder | ZSW960x3800 | 1 |

| 3 | Jaw Crusher | PE500x750 | 1 |

| 4 | Impact Crusher | PF1010 | 1 |

| 5 | Vibrating Screen | 4YK1860 | 1 |

| 6 | Belt conveyor | B800 | 2 |

| 7 | Belt conveyor | B650 | 1 |

| 8 | Belt conveyor | B500 | 5 |

Soft rock (such as limestone, shale, mudstone, and coal gangue) has medium-to-low hardness, is easily crushed, and exhibits low abrasiveness, making it suitable for small- to medium-sized sand and gravel aggregate production lines (50-90 tons/hour). The PF1010 impact crusher, with its high crushing efficiency, excellent finished product shape, and low maintenance costs, is an ideal choice for soft rock crushing.

• Feed Size: ≤350mm (primary crushed material from the jaw crusher)

• Discharge Size: ≤30mm (adjustable to meet the requirements of concrete aggregate or asphalt mixture)

• Capacity: 50-90tph, completes a production line when combined with a PE600×900 jaw crusher or vibrating feeder.

• Good particle shape: High proportion of cubes, low proportion of flakes (superior to hammer crushers)

• Low dust content: The "rock-on-rock" principle of the impact crusher reduces over-crushing

• Reasonable gradation: Can be used directly in commercial concrete plants or asphalt mixing plants

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!