Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The PF1214 impact crusher has become a star product in the sand and gravel aggregate industry thanks to its high efficiency, energy-saving features, and strong adaptability. Whether crushing limestone, granite, or construction waste, it provides a stable and reliable solution. Choosing the right configuration and performing regular maintenance can significantly improve production efficiency and reduce operating costs!

The impact crusher utilizes a "rock-on-rock" + "rock-on-iron" crushing principle, resulting in a predominantly cubic output with low flake content. It is particularly suitable for high-demand aggregate production applications such as highways, high-speed rail, and commercial concrete plants.

Compared to cone crushers, the PF1214 consumes 15%-20% less energy and is easily maintained, with blow bars requiring only 1-2 hours to replace.

By adjusting the gap between the impact plate and the blow hammer, the discharge particle size can be easily controlled (adjustable from 0-50mm) to meet different customer needs.

| Model | PF-1214 |

|---|---|

| Feeder Opening Size(mm) | 480X1500 |

| Max. Feeding Size(mm) | 350 |

| Rotor sizeD*L(mm) | Φ1250X1400 |

| Motor Power(kw) | 132-160 |

| Capacity(t/h) | 100-180 |

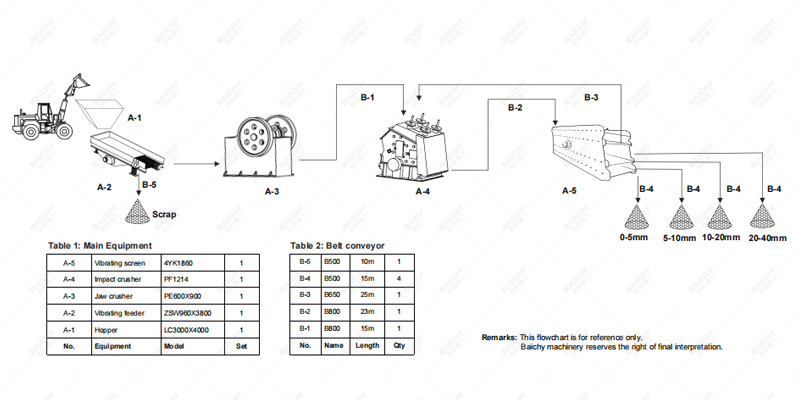

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | LC3000x4000 | 1 |

| 2 | Vibrating feeder | ZSW9638 | 1 |

| 3 | Jaw Crusher | PE600x900 | 1 |

| 4 | Impact Crusher | PF1214 | 1 |

| 5 | Vibrating Screen | 4YK1860 | 1 |

| 6 | Belt conveyor | B800 | 2 |

| 7 | Belt conveyor | B650 | 1 |

| 8 | Belt conveyor | B500 | 5 |

In small and medium-sized sand and gravel aggregate production lines, the PF1214 impact crusher is an ideal choice for limestone processing due to its efficient crushing, excellent particle shape, and easy maintenance.

• Primary Crushing: Choose a small jaw crusher (such as the PE600×900) or directly use the PF1214 (if the feed size is ≤400mm).

• Secondary Crushing: The PF1214 impact crusher (the main equipment, responsible for secondary crushing).

• Screening: The 4YK1860 vibrating screen (double-deck screen, grading 0-5mm, 5-10mm, and 10-20mm).

Q: Can the PF1214 be used in a 400 tons per hour limestone production line?

A: Two PF1214 units must be used in parallel, or upgraded to the PF1315 model (single unit capacity 400-600 t/h).

Q: Compared to a cone crusher, what are the production capacity advantages of the PF1214?

A: Impact crushers are more suitable for low- to medium-hardness materials, offering high production capacity and finer (more angular) particle shape. Cone crushers are more wear-resistant but have 10%-15% lower production capacity.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!