Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

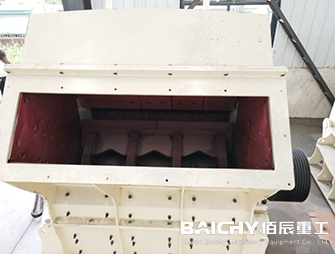

In the sand, gravel, aggregate, and mineral crushing industries, the PF1210 impact crusher is redefining the efficiency standard for medium and fine crushing operations with its unique crushing principle and superior performance.

Unlike conventional impact crushers, the PF1210 utilizes a three-stage progressive crushing chamber design:

• Primary impact zone: A large opening (650×350mm) processes the initial material.

• Secondary grinding zone: Specially angled impact plates achieve mutual grinding of the material.

• Final shaping zone: Adjustable impact liners ensure the final particle shape.

This structure improves crushing efficiency by over 40% for materials with a compressive strength ≤350 MPa (such as granite and limestone).

The PF1210 impact crusher utilizes a heavy-duty rotor structure with a rotor diameter of 1250 mm and a rotor length of 850 mm, creating the best balance between centrifugal force and linear velocity among similar equipment.

| Model | PF-1210 |

|---|---|

| Feeder Opening Size(mm) | 450X1150 |

| Max. Feeding Size(mm) | 300 |

| Rotor sizeD*L(mm) | Φ1250X1050 |

| Motor Power(kw) | 70-130 |

| Capacity(t/h) | 90-110 |

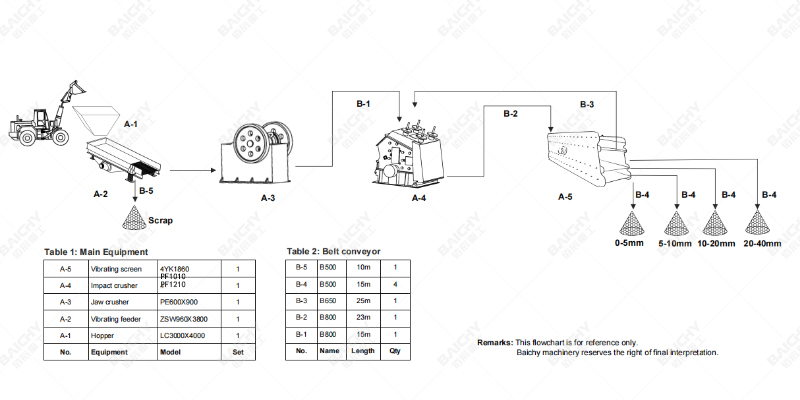

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | LC3000*4000 | 1 |

| 2 | Vibrating feeder | ZSW960x3800 | 1 |

| 3 | Jaw Crusher | PE600x900 | 1 |

| 4 | Impact Crusher | PF1010、PF1210 | 1 |

| 5 | Vibrating Screen | 4YK1860 | 1 |

| 6 | Belt conveyor | B800 | 2 |

| 7 | Belt conveyor | B650 | 1 |

| 8 | Belt conveyor | B500 | 5 |

In today's intensive development of the sand and gravel aggregate industry, 100tph gravel production lines have become the mainstream configuration for small and medium-sized sand and gravel plants. The PF1210 impact crusher, with its unique performance advantages, is playing an increasingly critical role in these lines.

In a standard 100tph limestone crushing line, the PF1210 is typically used as the secondary crushing unit, resulting in the following efficient configuration:

• Primary Crushing: PE600×900 Jaw Crusher (Feed Size ≤ 500mm)

• Secondary Crushing: PF1210 Impact Crusher (Feed Size ≤ 350mm)

• Screening System: 3YK1860 Vibrating Screen (Closed-Circuit)

In this configuration, the PF1210 perfectly fulfills the critical role of "bridging the gap," converting the coarse crushed material output from the jaw crusher into high-quality aggregates sized 0-31.5mm.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!