Contact us for a quote and free process design

Baichy know what you are expecting from mining project and we are making it happen with unrivalled products and services.

Leave Message

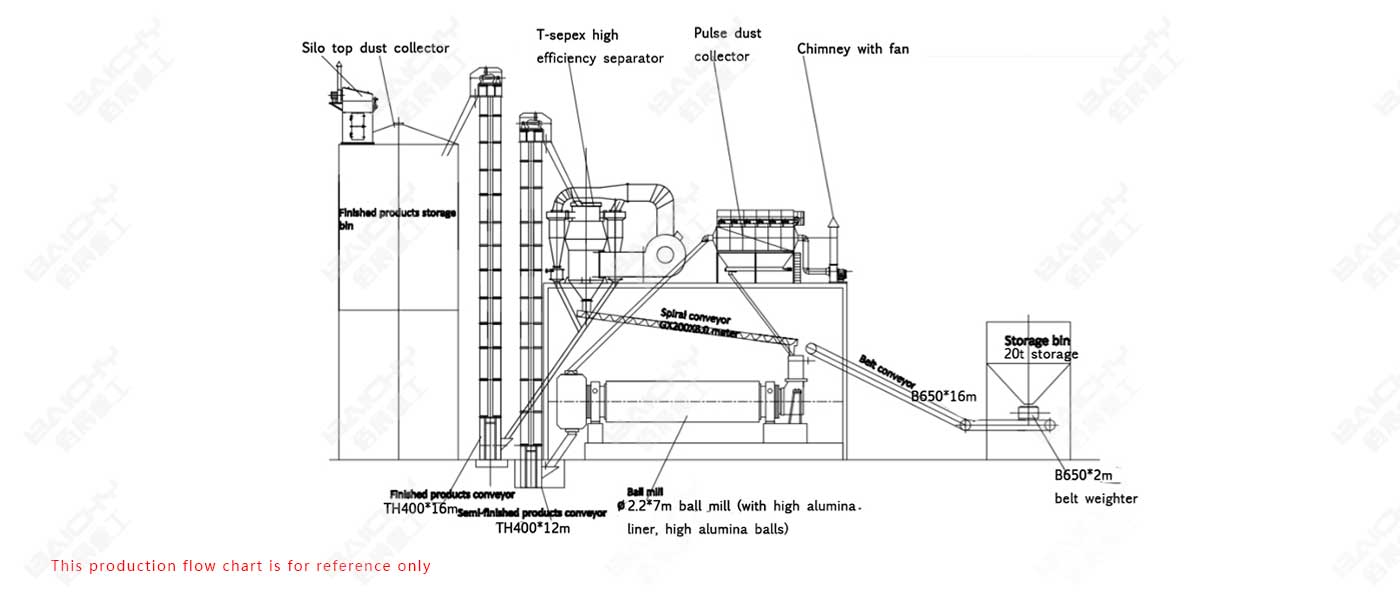

| Equipment list | Jaw crusher, Ceramic ball mill, Air classifier, Pulse dust collector, Bucket elevator, Belt conveyor and etc. |

| Raw materials | Feldspar, Quartz |

| Mohz hardness | 6.0-6.5 |

| Feeding size | <25mm |

| Capacity | 1-30tph |

| Output size | 200-425mesh |

| Application | glass, ceramic, fillers, enamel frits and glazes, construction industries and etc. |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery