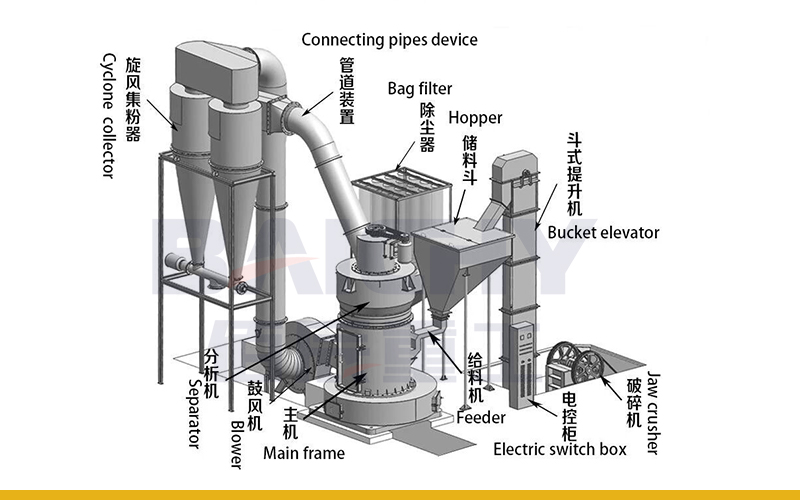

The working principle of the grinding mill mainly involves processes such as material crushing, fine powder separation, and collection. For the Raymond grinding mill, its working principle can be summarized in detail as follows:

The motor drives the main machine to rotate through the reducer. The speed of the main machine is usually determined by the power of the motor and the material of the grinding disc. The material enters the mill from the feed port through the feeding device and enters the powder stage.

The grinding effect of the Raymond mill:

1. The material is ground by the extrusion, grinding, and friction between the grinding disc and the grinding roller inside the main machine.

2. Abrasives of certain specifications and density are installed on the grinding disc and the grinding roller. When the material contacts the abrasive, the grinding and refinement process will occur.

3. When the material enters the grinding area, it is brought to the front area of the grinding roller under the action of the plow-shaped guide blades under the grinding roller.

4. The grinding roller revolves and rotates around the vertical axis under the action of the device hanging on the plum blossom frame. Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring, so that the scraper scoops up the material and sends it between the grinding roller and the grinding ring. The purpose of crushing the material is achieved due to the rolling and crushing of the grinding roller.

After the grinding work is completed, it enters the powder separation:

1. The material after grinding enters the separator, and the cyclone separation of the separator separates the powder from the airflow.

2. The coarse powder returns to the grinding disc by gravity for re-grinding, while the fine powder enters the dust collection device through the air duct.

The fine powder is collected by the dust collection device and then sent to the powder storage bin or for further processing through the conveying device. The airflow separated by the separator is discharged from the mill through the exhaust device to maintain the stable flow of the airflow in the equipment.

Through this series of precise and complex steps, the Raymond grinding mill realizes the transformation from raw materials to fine powder and is widely used in material processing in various mineral, chemical, construction, and other industries. Its high efficiency, uniform crushing effect, and stable operating performance make it occupy an important position in the field of grinding equipment.