Wet Pan Mill For Gold

Wet Pan Mill: The Gold Grinding Tool in Gold Ore Processing

In the wet beneficiation process of gold ore, fine grinding of the ore is a crucial step in releasing gold particles and improving recovery rates. Among numerous grinding equipment options, the wet pan mill, with its simple structure, low investment cost, easy operation and maintenance, and especially its suitability for the free grinding of precious metals such as gold and silver, has become the preferred equipment for many small and medium-sized gold mines and processing plants worldwide. As a professional manufacturer with 20 years of experience in mining equipment manufacturing, we will provide you with a comprehensive analysis of this classic gold grinding machine.

| Key Words | Wet Pan Mill For Gold |

|---|---|

| Product Model | Wet Pan Mill |

| Feed Size | ≤30mm |

| Motor Power | 3-30kw |

| Capacity | 3-20t/h |

| Core Functions | Kinetic energy transfer + abrasion + hydraulic classification |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Wet Pan Mill Working Principle and Overview

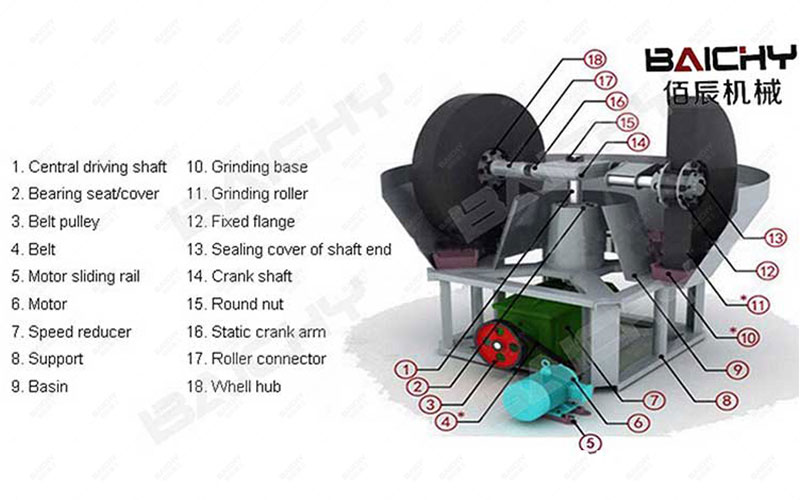

Gold grinding machine structural diagram

How Does It Work?

The wet pan mill, also known as a wet grinding mill or gold ore mill, operates on the core principle of compression, grinding, and crushing. During operation, the electric motor drives the central vertical shaft through a pulley, causing the two heavy grinding wheels at the bottom to rotate in a circular motion within the circular grinding pan. The crushed ore (usually less than 25mm) and water are continuously fed in proportion through the feed port. Under the enormous centrifugal force of the grinding wheels, the material is repeatedly compressed and frictionally ground between the grinding wheels and the bottom plate of the grinding pan, eventually being ground into a slurry (fineness usually reaching 100-200 mesh). The qualified slurry overflows from the edge of the grinding pan and enters the next classification or gold extraction process. The entire process is wet, effectively avoiding dust and enabling continuous operation.

Structural diagram of a wet type gold grinding machine

Main Components of the Equipment

A standard wet pan mill mainly consists of the following parts:

1. Base and frame: Providing stable support.

2. Grinding pan: A container for holding ore and water, lined with high-strength wear-resistant steel plates or stone.

3. Grinding wheels: The core working parts, cast from high-chromium alloy or special steel, extremely wear-resistant.

4. Central vertical shaft and transmission system: The core for transmitting power.

5. Reducer and motor: Providing stable speed and torque.

Why Choose a Wet Pan Mill? Its Irreplaceable Advantages

After 20 years of technological improvements and market validation, we have found that wet grinding mills offer significant advantages in specific application scenarios:

• Low investment and operating costs: Compared to ball mills, their purchase cost, installation foundation, and power consumption are lower, making them ideal for projects with limited budgets or fluctuating ore grades.

• Excellent free gold recovery capability: During the grinding process, amalgamation or initial contact with chemical reagents can be completed simultaneously, effectively capturing liberated free gold and preventing losses caused by over-grinding, resulting in excellent gold recovery rates.

• Simple structure, robust and durable: The mechanical structure is simple, with fewer failure points, making it easy to operate and maintain. The core wear parts (grinding wheels, liners) have a long service life, reducing downtime for replacement.

• Strong adaptability: It can not only process gold ore but also has good grinding effects on various metal ores such as silver, lead, tungsten, and molybdenum, and is especially suitable for sticky ores.

Gold grinding machine customer site

Sharing of Practical Application Cases

In a medium-sized hard rock gold mine project in Africa, the client originally used a traditional process of jaw crusher + hammer crusher + ball mill, which was costly and complex. We recommended a simpler jaw crusher + wet grinding mill solution. We provided a Φ1200 wet grinding mill with a processing capacity of 1-2 tons/hour and a feed size of ≤20mm. The operating results showed that the grinding fineness was stably maintained at 75% passing -200 mesh, perfectly matching the oxidation leaching system, increasing the gold recovery rate from the original 85% to over 92%, and reducing overall power consumption by approximately 30%. The client was very satisfied with the return on investment.

Recommended Related Equipment and Integrated Production Lines

Wet grinding mills rarely operate alone and are usually part of a high-efficiency gold beneficiation equipment production line. We recommend the following integrated configuration:

• Feeding: Jaw crusher (for primary crushing) → roller crusher/hammer crusher (for secondary and fine crushing).

• Grinding: Wet grinding mill (core grinding and initial recovery).

• Classification: Spiral classifier or hydrocyclone (to control grinding fineness). • Extraction: Centrifugal gold concentrator/Nelson concentrator (for recovering coarse gold), leaching and adsorption tanks (for oxidative leaching of fine gold), shaking table (optional).

• Auxiliary equipment: Mixing tanks, dosing machines, etc.

Frequently Asked Questions (FAQ) about Wet Pan Mills

1. What are the main differences between a wet pan mill and a ball mill?

Wet pan mills primarily rely on crushing pressure, combining grinding and slight stirring functions. They are suitable for processing brittle ores containing free gold, emphasizing grinding and recovery simultaneously. Ball mills primarily rely on impact and grinding forces, offering higher grinding efficiency and more uniform fineness. They are suitable for large-scale, continuous production requiring fine grinding, but also have higher investment and energy consumption. The choice depends on the ore properties, scale, and economics.

2. What are the key wear parts of a wet pan mill? What is their replacement cycle?

The core wear parts are the grinding wheels and the grinding pan liners. Their lifespan depends on the ore hardness, grinding particle size, and material. Our high-chromium alloy wear parts typically last 6-12 months under medium-hardness gold ore conditions. We provide comprehensive spare parts supply services.

3. How do I determine the appropriate wet pan mill model and specifications for my mine?

The main factors are: 1) Processing capacity (tons/day or hour); 2) Feed and discharge particle size; 3) Physical properties of the ore (hardness, viscosity, moisture content). Our technical team can conduct free grinding tests based on your ore samples and provide the best model (such as Φ900, Φ1100, Φ1200, Φ1300, Φ1500, etc.) and a complete mineral processing equipment solution.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.