Wet Ball Mill

Introduction

In the entire mineral processing process, from coarse crushing and intermediate crushing to fine grinding, every stage is crucial. As a professional manufacturer of mobile mining crushing equipment, we not only focus on front-end crushing solutions but also deeply understand the principles and efficiency of subsequent grinding processes. Wet ball mills are key equipment for achieving efficient mineral liberation in modern concentrators. This article will delve into the working principle of wet ball mills, revealing how they transform crushed ore into suitable products for separation.

| Key Words |

1 t/h 900x1800 Small Ball Mill |

| Product Model |

Wet Ball Mill |

| Feed Size |

≤25mm |

| Motor Power |

18.5-4500kw |

| Capacity |

0.65-615t/h |

| Core Functions |

Grinding precision and particle size controllability |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Analysis of Wet Ball Mill Working Principle

The working principle of a wet ball mill is based on the combination of three mechanical actions: impact, grinding, and attrition, and is a continuous crushing process completed in a rotating cylinder with the participation of a water medium. Its core objective is to achieve effective single-particle liberation of minerals, creating optimal conditions for subsequent separation operations (such as flotation).

Core Components and Working Process

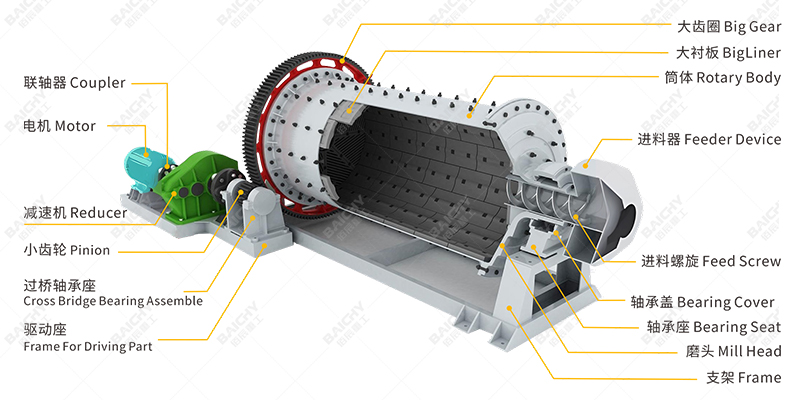

A typical wet ball mill mainly consists of a cylinder, end covers, main bearings, a transmission system (large gear, small gear, motor), a feeding section, a discharge section, and internal liners and grinding media (steel balls). Its working process can be summarized as follows:

Feeding: Ore with suitable particle size, processed by the front-end crushing system, is mixed with water in a certain proportion to form a slurry, which is continuously fed into the cylinder from the feeding end.

Grinding: The cylinder rotates driven by the transmission system, lifting the internal grinding media (steel balls) and material to a certain height. When the media rises to a point where its own gravity is greater than the centrifugal force, it falls in a parabolic trajectory, generating strong impact and crushing effects on the material at the bottom of the cylinder. During the rising and rolling process, continuous grinding and attrition also occur between the media and the material, and between the material particles themselves.

Role of the water medium: Water plays multiple roles in this process: firstly, as a transport carrier, allowing the material to flow in the form of a slurry, facilitating feeding and discharging; secondly, it acts as a lubricant and dispersant, preventing the agglomeration of fine particles and carrying away the qualified fine particles, reducing "over-grinding"; thirdly, it acts as a process medium, directly participating in the subsequent wet separation process.

Discharge: The finely ground slurry is discharged from the other end of the cylinder through overflow, grate plate forced discharge, or peripheral discharge, and then enters a classification device (such as a hydrocyclone) for inspection and classification. The qualified fine particles become the product, while the coarse particles are returned to the wet ball mill for further grinding, forming a closed-loop cycle.

Analysis of Grinding Media Movement State

The movement state of the grinding media inside the cylinder is crucial in determining the efficiency of the wet ball mill, and mainly falls into three states:

Cascading: At low rotational speeds, the media rises with the cylinder to a certain height and then slides down, primarily performing grinding action with low impact force.

Throwing: At the optimal operating speed, the media is lifted to the highest point and then thrown along a parabolic trajectory, resulting in strong impact force and high crushing efficiency. This is the main operating state pursued by industrial wet ball mills.

Centrifugal: At excessively high rotational speeds, the media rotates with the cylinder, losing relative motion, and having almost no crushing effect. This should be avoided.

Inherent Advantages of Wet Grinding Compared to Dry Grinding

Understanding the principle allows us to more deeply appreciate the inherent advantages of wet ball milling:

Efficiency Advantage: The water medium can promptly remove qualified particles, avoiding the common "cushioning layer" and fine powder "agglomeration" phenomena in dry grinding, allowing the impact energy to act more effectively on the coarse particles to be crushed, thus improving grinding efficiency.

Environmental Protection and Safety Advantages: The entire wet operation process completely suppresses dust generation, fundamentally solving occupational health and safety and environmental protection problems.

Process Advantages: The resulting slurry can be directly pumped to the next wet process (such as flotation), resulting in a natural and smooth process flow and more economical energy consumption.

Case Study: How Principles Guide Practice – Optimizing a Certain Iron Ore Wet Ball Milling Operation

A large magnetite concentrator plant initially experienced lower than expected production capacity in its wet ball milling system. Through in-depth analysis of its working principles, technicians determined that the problem might lie in the media movement state and classification efficiency. After calculations and adjustments, the ball mill's rotational speed was fine-tuned to a more optimal "throwing" working range, the size ratio of the steel balls was optimized (increasing the impact force), and the operating parameters of the supporting hydrocyclone were adjusted. These adjustments, based on core principles, have increased the processing capacity of the wet ball mill by approximately 15%, while reducing over-grinding. This provides a more ideal feed particle size for subsequent magnetic separation, ultimately improving both concentrate grade and recovery rate.

System Synergy: From Efficient Crushing to Efficient Grinding

An optimized crushing and grinding system is interconnected. As mobile crushing experts, we emphasize the importance of the front end providing the best "raw materials" for the back end:

Our mobile jaw crushers and mobile cone crushers can be deployed near the mining site, efficiently crushing the raw ore to an ideal particle size range of approximately -20mm. This provides a stable, uniform, and appropriately sized feed for the subsequent wet ball mill.

Optimizing the feed particle size significantly reduces the input particle size of the wet ball mill, thereby directly reducing its energy consumption per ton (according to Bond's Law) and increasing its overall processing capacity. This "more crushing, less grinding" synergistic design is key to reducing total production costs from a system perspective.

Mobile Jaw Crusher

Mobile Cone Crusher

Frequently Asked Questions (FAQ)

Q1: What are the key operating parameters that determine the grinding efficiency of a wet ball mill?

A1: The key parameters mainly include: ① Mill speed: This determines whether the steel balls are in a "cascading," "throwing," or "centrifugal" state. The optimal speed is usually 65%-85% of the critical speed. ② Steel ball filling rate and grading: The amount of steel balls loaded (usually 25%-45% of the effective volume of the cylinder) and the proportion of large, medium, and small balls directly affect the impact and grinding effect. ③ Grinding concentration: The percentage of solid content in the slurry; too high or too low a concentration will affect efficiency and product particle size.

Q2: Is the "water" in the wet ball mill only used for dust control? How is the amount of water determined?

A2: No, the role of water is far more than just dust control. It is a combination of transport medium, dispersant, process medium, and coolant. The amount of water added (forming a certain liquid-solid ratio with the ore) needs to be strictly controlled. If too little water is added, the pulp becomes too viscous and has poor fluidity, easily leading to "clogging"; if too much water is added, the pulp becomes too dilute, reducing the impact effect of the steel balls and the grinding efficiency, while also increasing unnecessary pumping energy consumption. The optimal concentration needs to be determined through ore testing.

Q3: If my ore will be subsequently processed by dry separation (e.g., dry magnetic separation), can I still use a wet ball mill?

A3: This is usually not economical. Although technically feasible (the pulp produced by wet ball milling can be filtered and dried to obtain dry powder), it means adding complex and energy-intensive processes such as dewatering and drying after grinding, which greatly increases investment and operating costs. For processes with subsequent dry separation, dry ball mills should be prioritized in principle, unless the ore has special properties (such as being extremely prone to mudding or stickiness), where wet grinding offers irreplaceable advantages.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!