PEX 250x750 Jaw Crusher

Recently, we've noticed mining clients in Peru actively seeking a specific model of jaw crusher: the "250 x 750 jaw crusher." This is no coincidence; it precisely reflects the core needs of small and medium-sized mines and quarries in Peru: a jaw crusher that achieves a perfect balance between feed size, processing capacity, and equipment investment.

The 250 x 750 jaw crusher model clearly indicates its key technical parameters: a feed opening size of 250mm x 750mm. This means it can efficiently process stone with a maximum feed side length of no more than 210mm. Its hourly processing capacity typically ranges from 15 to 50 tons, depending on the material hardness and output particle size. With its robust structure and ease of maintenance, it is the ideal choice for crushing various ores and rocks with a compressive strength not exceeding 320 MPa, and is often used as the first coarse crushing stage in a crushing production line.

| Key Words | Jaw Crusher Solution for Peruvian Mines |

|---|---|

| Product Model | PEX Jaw Crusher |

| Feed Size | ≤250mm |

| Motor Power | 15-55kw |

| Capacity | 5-105t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

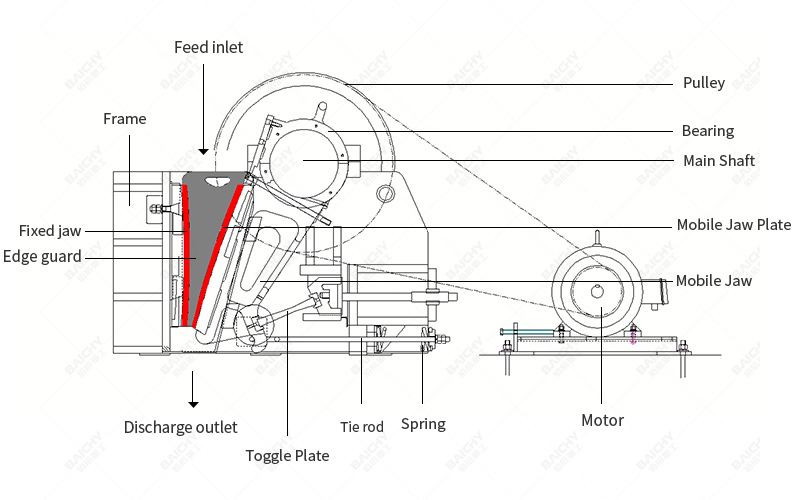

Fine jaw crusher structure diagram

Core Advantages: Superior Performance from 20 Years of Manufacturing Experience

Leveraging two decades of technological accumulation, we have continuously optimized this classic 250 x 750 model, making it even more competitive in the market.

Superior Reliability and Durability

The frame is welded from high-quality steel plates and annealed to eliminate internal stress, ensuring high strength and stability under the complex working conditions of Peru's high-altitude mining areas. The moving jaw assembly has a robust structure, and the bearing housing is made of integral cast steel, resulting in stronger load-bearing capacity and a longer service life.

Highly Efficient Crushing Ratio and Discharge Adjustment

The jaw crusher adopts a "V"-shaped cavity design, combined with a deep cavity and no dead zones, achieving a higher crushing ratio and uniform finished product particle size. The discharge port uses a wedge adjustment device with a large and flexible adjustment range, which can quickly meet the different requirements of various customers for the final product particle size.

Easy Maintenance and Economical Operation

All components are easy to disassemble and replace, the lubrication system is centralized, and daily maintenance workload is minimal. The equipment has a simple structure and low power consumption. In the long run, it can significantly reduce the overall operating costs for Peruvian customers, making it a truly cost-effective choice.

Success Stories: Our Equipment's Application in Global Mines

Our 250 x 750 jaw crusher is not only highly praised in the Chinese market, but has also been successfully exported to many countries and regions in Southeast Asia, Africa, and South America. For example, in a medium-sized copper mine's associated stone processing project in Chile, Peru's neighbor, one unit of this model has been operating stably for over three years, crushing associated basalt to provide aggregate for infrastructure construction. Its excellent output particle size and extremely low failure rate have earned high praise from the owner. This fully demonstrates the adaptability and reliability of our products as a seasoned manufacturer of mining crushing and grinding equipment.

Related Equipment Recommendations

To meet the more complete production line needs of our Peruvian customers, we typically recommend pairing the 250 x 750 jaw crusher with the following equipment to form a high-efficiency production line:

• Secondary Crushing Equipment: Such as the PF-1210 impact crusher or PYB-1200 cone crusher, for medium and fine crushing.

• Screening Equipment: 3YA-1860 vibrating screen, for material classification.

• Feeding and Conveying Equipment: Several ZG-96 vibrating feeders and belt conveyors.

Frequently Asked Questions (FAQ)

Q1: What types of materials are best suited for crushing with this 250 x 750 jaw crusher?

A1: It is ideal for crushing various minerals and rocks, including limestone, bluestone, granite, basalt, pebbles, iron ore, and copper ore, with a recommended compressive strength not exceeding 320 MPa.

Q2: What is the power and approximate weight of the equipment? Is a special foundation required?

A2: This model is typically equipped with a 37-45kW motor, and the total weight is approximately 7.5 tons. It requires a robust concrete foundation to ensure stable operation. We will provide foundation installation diagrams to guide construction.

Q3: Do you provide technical support and spare parts services for overseas customers?

A3: Of course. As an international manufacturer of mining crushing and grinding equipment, we provide detailed installation manuals and operation training videos for all exported equipment. We have established a global spare parts supply network to ensure timely technical support and spare parts supply services for customers in regions such as Peru.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!