Quartz Sand Wet Grinding Ball Mill

Wet Grinding Ball Mill for Quartz Sand: The Core Tool for High-Efficiency Purification and Fine Processing

As a manufacturer with 20 years of experience in the field of mineral processing equipment, we deeply understand the impact of every stage of quartz sand processing on the final product quality and economic benefits. Among numerous processing equipment, the wet grinding ball mill for quartz sand is undoubtedly a key piece of equipment for achieving fine grinding, purity improvement, and stable production of minerals. This article will provide you with a comprehensive analysis of this core equipment.

Why Choose Wet Grinding?

Quartz sand, whose main component is silicon dioxide, is widely used in high-tech industries such as glass, ceramics, casting, building materials, and photovoltaics. These applications have extremely stringent requirements for the particle size, purity, and impurity content (especially iron content) of quartz sand. Compared with dry grinding, the wet grinding process demonstrates irreplaceable advantages in quartz sand processing: it effectively prevents dust dispersion, reduces iron contamination (because water can act as a buffer and remove iron), and can more efficiently achieve the liberation of inpidual mineral particles, resulting in a finer and more uniform particle size distribution.

The Core Role of the Ball Mill

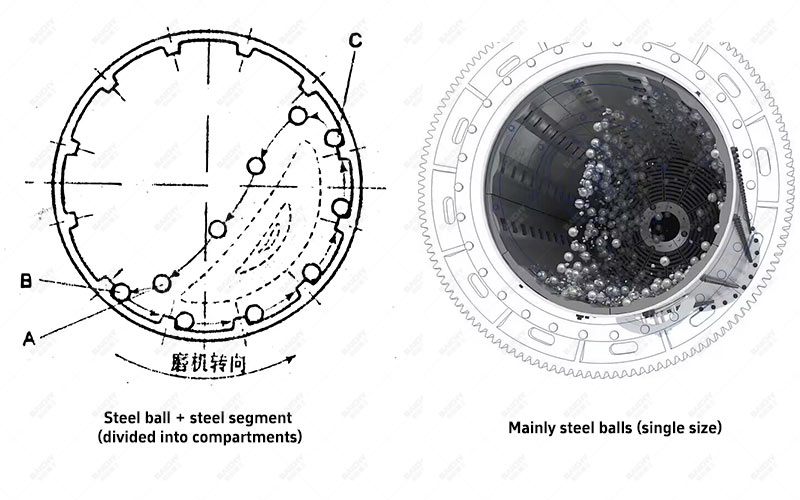

In the wet grinding process line, the ball mill undertakes the core grinding and crushing task. Through the rotation of the cylinder, it drives the internal grinding media (such as steel balls, ceramic balls, or silica balls) to impact, grind, and abrade the quartz sand material. Under the combined action of the water medium, the material is gradually ground to the target fineness.

Outstanding Advantages of Wet Grinding Ball Mills

High Purity Assurance

Using the wet grinding process, combined with appropriate liners and grinding media (such as high-alumina ceramic balls and silica liners), the introduction of harmful impurities such as iron during the processing can be minimized, ensuring the high purity of the finished quartz sand product from the process source. This is crucial for the production of high-end glass and photovoltaic quartz sand.

High Grinding Efficiency and Uniform Particle Size

The water medium has good fluidity and can promptly remove materials that have met the fineness requirements from the grinding zone, avoiding over-grinding, thereby improving grinding efficiency. At the same time, the wet environment allows for better material dispersion, making it easier to obtain products with a concentrated particle size distribution and better particle morphology.

Stable Operation, Environmentally Friendly and Energy-Saving

The wet ball mill system operates in a closed loop, free from dust pollution, creating a friendly working environment. It operates with relatively low noise levels, and modern equipment is typically equipped with advanced energy-saving drive systems and automatic control systems, achieving stable, energy-efficient, and environmentally friendly production.

Classic Application Case Sharing

A large domestic photovoltaic glass sand producer had an existing production line with unstable iron content and low particle size compliance rates. Our company customized a large-scale wet grinding ball mill for them, using a special rubber liner and high-density silica ball combination, and optimized the water intake, slurry concentration, and discharge classification system. After the upgrade, the iron content of the product decreased by more than 30%, the -200 mesh particle size pass rate stabilized at over 99.5%, and the annual production capacity increased by 25%, bringing significant economic benefits to the customer.

Equipment Selection and Process Matching Recommendations

When selecting a wet ball mill for quartz sand, it is necessary to consider the characteristics of the raw ore, production capacity targets, finished product particle size, and investment budget. We recommend:

1. Equipment Selection: Select the cylinder size based on the processing capacity, and determine the length-to-diameter ratio based on the required product fineness (for ultra-fine grinding, a long-cylinder type can be considered).

2. Liners and Media: For high-purity quartz sand, we recommend using silica liners with silica balls, or high-alumina ceramic liners with ceramic balls; for foundry sand with slightly less stringent iron content requirements, wear-resistant rubber liners with special steel balls can be used to reduce costs.

3. Supporting Processes: Ball mills usually need to be combined with hydrocyclones or vibrating screens to form a closed-loop circulation system to control the final product particle size. A magnetic separator is recommended at the front end for pre-iron removal, and a dewatering screen or filter press can be connected at the back end for solid-liquid separation.

Frequently Asked Questions (FAQ)

What are the main differences between wet ball mills and dry ball mills in quartz sand processing?

The main differences lie in the grinding environment and product characteristics. Wet grinding is dust-free, has less iron contamination, and produces more uniform particle sizes, making it suitable for producing high-purity, ultra-fine quartz sand, but subsequent dewatering and drying are required. Dry grinding is a simple process that does not require dewatering, but it is prone to dust pollution and iron contamination, resulting in a relatively wide particle size distribution.

How to control the final fineness of quartz sand after wet grinding?

The final fineness is mainly controlled by adjusting the grinding concentration, feeding speed, and the parameters of the classification equipment (such as hydrocyclones). Inside the ball mill, the grading of the grinding media (ratio of large to small balls) is one of the core factors determining grinding efficiency and product fineness.

How to minimize iron contamination during the operation of a wet ball mill?

There are three key measures: First, use non-metallic liners and grinding media, such as silica, ceramics, or polymer materials; second, install a strong magnetic separator before the grinding process to pre-remove iron impurities from the raw ore; and third, regularly inspect and replace worn liners and media to prevent metal wear particles from mixing into the product.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.