Vertical Shaft Impact Crusher Machine | Sand Crusher Machine

As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing comprehensive solutions for the global mining industry. Among numerous pieces of equipment, the vertical shaft impact crusher (VSI) has become a core piece of equipment in the sand and gravel crushing field due to its high efficiency and flexibility. This article will provide an in-depth analysis from multiple perspectives, including its working principle, product advantages, application scenarios, and practical cases, to help you fully understand this key piece of equipment.

Product Overview

The vertical shaft impact crusher (VSI) is a high-efficiency device that uses a high-speed rotating rotor to accelerate and crush materials through impact. Its unique design allows materials to be crushed within the crushing chamber through the stone-on-stone or stone-on-iron principle, making it particularly suitable for shaping, sand making, and fine crushing of medium-hard and harder materials. This equipment is widely used in mining, construction, railway, and other fields, and is one of the core pieces of equipment in modern sand and gravel aggregate production.

Product Advantages

1. High Efficiency and Energy Saving: Optimized crushing chamber design and rotor structure increase crushing efficiency by approximately 30% compared to traditional equipment, while reducing energy consumption by more than 20%.

2. Excellent Finished Particle Shape: Utilizing impact crushing, the produced material exhibits a high cubic ratio and reasonable gradation, making it particularly suitable for high-standard concrete aggregate production.

3. Multifunctional Integration: The same equipment can perform crushing, shaping, and sand making, reducing process steps and equipment investment.

4. Easy Maintenance: The core components adopt a modular design, allowing for quick replacement of wear parts and effectively reducing downtime.

5. Environmentally Friendly and Low-Noise: The enclosed structure combined with dust collection design results in low operating noise, with dust emissions meeting international environmental standards.

6. Intelligent Control: An optional intelligent monitoring system can be added to monitor equipment operating status in real time, enabling predictive maintenance.

Application Scenarios

• Sand and Gravel Aggregate Production: Used for sand making and shaping of materials such as limestone, granite, and basalt.

• Fine Crushing Operations in Mining: Suitable for third and fourth-stage crushing of metallic and non-metallic ores.

• Construction Waste Recycling: Processes concrete waste, bricks, and tiles to produce recycled aggregates.

• Railway and Highway Construction: Provides high-quality ballast and road base materials.

• Industrial Powder Pretreatment: Provides pre-crushing for grinding systems, improving overall system efficiency.

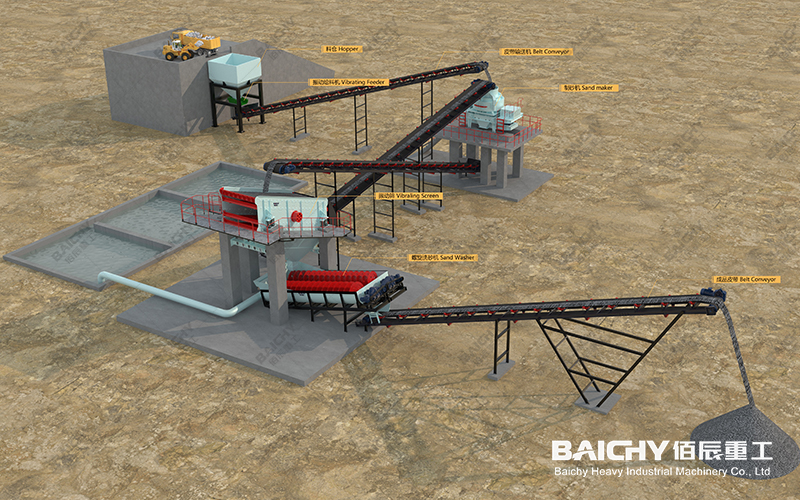

Sand making production line configuration scheme

Project Cases

Case 1: A Large-Scale Granite Aggregate Project in Southeast Asia

• Equipment Configuration: 2 VSI-1145 Vertical Shaft Impact Crusher

• Capacity: 350 tons/hour of high-quality manufactured sand

• Results: The fineness modulus of the finished sand can be controlled between 2.4 and 2.9, with needle-like and flaky content below 8%, completely replacing natural sand for local highway construction.

Case 2: A Limestone Sand Making Project in the Middle East

• Equipment Configuration: VSI-9526 Intelligent Vertical Shaft Crusher with Automatic Control System

• Features: Operated continuously for 18 months in a high-temperature and dusty environment, with an average utilization rate exceeding 94%.

• Benefits: Reduces overall production costs for customers by approximately 25%, achieving a rapid return on investment.

Frequently Asked Questions (FAQ)

Q1: What is the difference between a vertical shaft impact crusher and a cone crusher in sand making?

A1: Vertical shaft impact crushers primarily use stone-on-stone crushing, resulting in better particle shape, suitable for sand making and shaping; cone crushers primarily use layered crushing, with higher capacity, suitable for medium crushing. They are often used in combination for optimal efficiency.

Q2: What is the lifespan of key wear parts?

A2: Depending on the material hardness, the lifespan of vulnerable parts such as the throwing head and flow channel plates is typically 60-400 hours. We use high-chromium alloy and tungsten carbide composite materials and provide quick replacement solutions.

Q3: Does it support wet crushing?

A3: Yes. We can provide dedicated anti-clogging designs and components to adapt to high moisture content materials, and a fine sand recovery system to reduce waste.

Q4: How long does the equipment installation take?

A4: On-site installation of standard equipment takes approximately 7-10 days. We provide 3D foundation drawings, pre-assembled components, and full technical guidance to ensure rapid commissioning.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.