I. What is a Spiral Sand Washing Machine?

A spiral sand washing machine, also known as a spiral stone washing machine, is a key cleaning device in a sand and gravel aggregate production line. It primarily utilizes spiral blades to continuously agitate and propel sand and gravel materials within the washing tank. Under the combined action of water flow and friction and collision, it removes impurities such as mud and dust covering the sand and gravel surface, and breaks down the moisture layer surrounding the sand particles, thus achieving three main functions: washing, dehydration, and grading. It is one of the core pieces of equipment for producing high-quality, clean aggregates required for high-grade concrete.

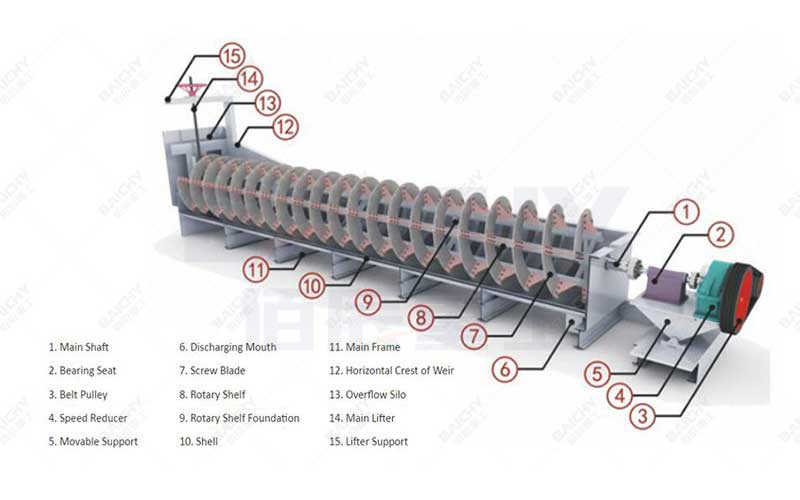

II. Working Principle and Structural Composition

1. Working Principle: After the material enters the sand washing tank through the feed inlet, it is tumbled and ground against each other by the continuously rotating spiral blades. Simultaneously, injected clean water carries away impurities such as mud and stone powder, which are discharged from the overflow outlet. The cleaned sand and gravel are gradually discharged from the discharge outlet at the bottom of the tank under the propulsion of the spiral blades, completing the washing process.

2. Main Structural Components:

• Tank: Container for holding materials and water, usually arranged at an angle.

• Screw Shaft: Core component, equipped with continuous spiral blades responsible for agitating and propelling the materials.

• Transmission Device: Includes a motor and reducer, providing power to the screw shaft.

• Support Frame: Supports the entire equipment.

• Discharge/Drainage Outlet: Used to discharge washed sand and gravel and wastewater, respectively.

III. Performance Advantages and Features

• High Cleaning Efficiency: Long screw length, long washing time, thorough washing, and significant cleaning effect.

• Large Processing Capacity: Suitable for large-scale, continuous sand and gravel production lines.

• Simple Structure and Stable Operation: Low failure rate, convenient maintenance, and long service life.

• Dewatering Function: The washed sand and gravel have low moisture content and can be used or transported directly.

• High Durability: Blades are usually equipped with wear-resistant liners, providing strong wear resistance.

IV. Spiral Sand Washing Machine vs. Bucket Wheel Sand Washing Machine

These are two common types of sand washing equipment. The main differences are as follows:

Characteristics: Spiral Sand Washing Machine vs. Bucket Wheel Sand Washing Machine

Working Principle: Spiral blades stir and propel; Bucket wheel rotates and washes.

Cleanliness: High, more thorough cleaning; Good.

Fine Sand Loss: Relatively high, requires fine sand recovery device; Very low, effectively maintains sand gradation.

Water Consumption: Higher; Lower, more environmentally friendly and water-saving.

Footage Area: Higher; Lower, compact structure.

Applicable Scenarios: Production lines with high cleanliness and high output; Situations requiring high fine sand retention and limited water resources.

V. Main Application Areas

Spiral sand washing machines are widely used in:

• Sand and gravel plants, mines, and building materials industries

• Water conservancy and hydropower projects, concrete mixing plants, and other construction projects

• Cleaning of quartz sand in glass factories

• Material washing and grading in industries such as metallurgy and chemicals

In summary, the spiral sand washing machine is a highly efficient and reliable large-scale sand and gravel cleaning equipment, particularly suitable for scenarios with large output and strict requirements for the cleanliness of the finished sand, acting as a "cleaning guardian".