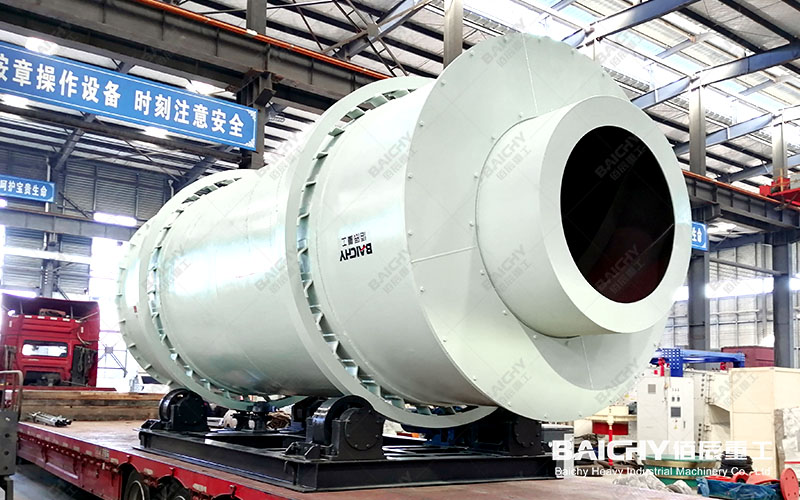

Three-Pass Rotary Dryer Manufacturer

In the mining, metallurgy, chemical, and building materials industries, material drying is a crucial link connecting upstream crushing and grinding with downstream deep processing or transportation. High moisture content in materials not only affects production efficiency but also increases transportation costs and impacts product quality. As a manufacturer of mining crushing and grinding equipment with twenty years of experience, we deeply understand the importance of the drying process. Today, we will provide an in-depth analysis of a piece of equipment that excels in efficiency and energy saving the three-stage rotary dryer.

| Product Name | Triple Pass Rotary Dryer |

|---|---|

| Brand | Baichy Heavy Industry |

| Place of Origin | Zhengzhou,China |

| Type | Three-cylinder Dryer |

| Capacity | 8-100tph |

| Motor Type | AC Motor |

| Motor Power | 11-88Kw |

| Application | Mines and quarries |

| Materials | Ores and hard materials |

| OEM/ODM | Acceptatble |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Customization options | customized on demand,sample processing... |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. What is a Three-Stage Rotary Dryer?

The three-stage rotary dryer, also known as a three-pass dryer, is a highly efficient and energy-saving continuous drying equipment based on an innovative design of the drum drying principle. Its core innovation lies in its three-stage structure: it consists of three concentric cylinders of different diameters nested together, forming three successively nested drying channels according to a specific structural combination.

During the drying process, the material does not pass through in a straight line like in a single-drum dryer, but instead, under the action of built-in lifting plates, it passes through the inner, middle, and outer cylinders in sequence, undergoing three reciprocating movements. This greatly extends the effective residence time and heat exchange path of the material inside the drum.

Working Principle and Core Advantages

II. Working Principle and Core Advantages

1. Unique Three-Stage Workflow:

◦ First Stage (Inner Cylinder): High-temperature hot air (approximately 600-800℃) and wet material first undergo intense co-current heat exchange in this area, rapidly evaporating surface moisture.

◦ Second Stage (Middle Cylinder): The material enters the middle cylinder through guide plates for counter-current drying. At this point, the hot air temperature has decreased, and the material mainly undergoes heat transfer through conduction and radiation, evaporating internally bound water.

◦ Third Stage (Outer Cylinder): The material finally enters the outer cylinder for co-current cooling and final drying. At this point, the material is close to the finished product temperature, and heat exchange with the outside air further reduces the discharge temperature, facilitating storage and transportation.

2. Outstanding Advantages Compared to Traditional Single-Drum Dryers:

◦ Extremely high thermal efficiency and significant energy savings: The unique structure greatly reduces the heat dissipation area of the cylinder (the outer surface area is only one-third of that of a single-drum dryer with the same output), and the heat energy utilization rate can reach 70%-80%, saving 40%-60% more coal than traditional single-drum dryers.

• Small footprint: The three-drum integrated design features a compact structure, with a length only about one-third that of a single-drum dryer, significantly saving factory space and infrastructure investment.

• Uniform and stable drying quality: The material undergoes a three-stage steaming-drying-drying process, resulting in more uniform heating and stable final moisture content, preventing over-drying or under-drying.

• Good environmental performance: The equipment has excellent overall sealing, minimizing dust leakage. It can be easily integrated with various dust removal equipment to easily meet environmental emission standards.

• Stable operation and low failure rate: Using roller support transmission, the operation is smooth, wear parts have a long service life, and maintenance costs are low.

III. Applicable Materials

The three-stage rotary dryer is especially suitable for loose, granular, and low-viscosity materials, making it an ideal choice for the mining and metallurgical industries, such as:

• Mining industry: Various ore particles, iron concentrate, magnetite, quartz sand, bentonite, clay, etc.

• Building materials industry: Slag, fly ash, cement raw materials, limestone powder, desulfurized gypsum, etc.

• Chemical industry: Calcium carbonate, kaolin, fertilizers, feed, etc.

IV. Value Commitment from Twenty Years of Manufacturing Experience

Based on twenty years of deep experience in crushing, grinding, and screening, we have a profound understanding of the physical properties of ores. This allows us to design and manufacture three-stage dryers with superior professional advantages:

• Personalized design: We can provide precise model selection and customized solutions based on the customer's initial moisture content, particle size, final moisture requirements, and output.

• System integration capabilities: We not only provide the drying host but also provide a complete system including feeding, heating (hot air furnace), dust removal, and discharge conveying, ensuring seamless connection and efficient operation of the production line.

• Process compatibility: Deep understanding of the upstream crushing and grinding processes ensures perfect matching of the drying stage with the preceding and subsequent processes, optimizing overall line efficiency and energy consumption.

• Reliable quality and service: Twenty years of technological accumulation ensures robust equipment materials and exquisite craftsmanship. We provide full-cycle service support, from installation guidance and commissioning training to lifetime maintenance. In today's pursuit of green mining and energy conservation, choosing an efficient drying equipment means lower production costs, superior product quality, and stronger market competitiveness. The three-stage rotary dryer, with its excellent energy-saving characteristics, stable drying performance, and compact structural design, has become the preferred drying solution for upgrading modern mineral processing production lines.