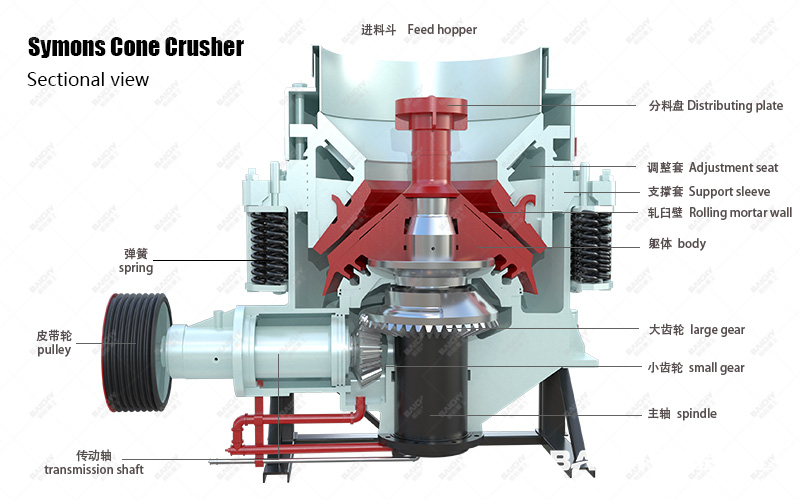

The Symons cone crusher (often referring to the Symons® standard cone crusher) is a type of medium and fine crushing equipment widely used in the mining, aggregate, and building materials industries. Its core operating principle is that the rotation of the eccentric sleeve causes the movable cone to oscillate, thereby squeezing and crushing the material. Understanding its internal structure is key to ensuring efficient and long-lasting operation.

I. Detailed Explanation of Core Components

The crusher can be pided into the following major systems to understand its components:

1. Crushing Chamber Assembly

This is the core component directly involved in crushing and is subject to the greatest wear and impact.

• Movable Cone:

◦ Function: Driven by the main shaft, it performs eccentric gyratory motion, working together with the fixed cone liner to form the crushing chamber and squeeze the material.

◦ Wear and Maintenance: The movable cone liner is installed on its surface and is the main wear part. It should be inspected regularly for wear and replaced promptly when output decreases or product particle size increases. The movable cone body should also be inspected for cracks or excessive wear.

• Cone Liner (Adjusting Ring Liner):

◦ Function: Fixed to the adjusting ring, it is a fixed part of the crushing chamber.

◦ Wear and Maintenance: Like the moving cone liner, it is a core, easily worn part. The moving cone liner and the cone liner should be replaced simultaneously if possible to ensure optimal crushing efficiency and particle shape.

• Main Shaft:

◦ Function: Transmits torque and supports the moving cone, making it a core load-bearing structural component of the equipment.

◦ Wear and Maintenance: It is subject to significant bending and torsional stresses. Pay special attention to its straightness and the presence of fatigue cracks on its surface. Damage can be extremely costly to repair.

2. Drive System: Responsible for transmitting the motor's rotational motion to the moving cone.

• Horizontal Shaft (Drive Shaft) and Gears:

◦ Function: The motor drives the horizontal shaft via a V-belt. The small gear on the horizontal shaft meshes with the large gear mounted on the eccentric sleeve, transmitting power to the eccentric sleeve.

◦ Wear and Maintenance: The gear pair requires good lubrication. Regularly check gear meshing clearance and tooth wear. Abnormal noise is often a precursor to gear problems.

• Eccentric Bushing:

◦ Function: Contains a bronze bushing inside and a large gear outside. Its rotational motion is converted into the oscillating motion of the moving cone.

◦ Wear and Maintenance: The bronze bushing between the eccentric bushing and the main shaft is a critical wear component. Poor lubrication can lead to rapid wear and even "burning" (seizing), causing serious downtime.

• Bearings:

◦ Function: Supports rotating components such as the horizontal shaft and eccentric bushing, reducing friction.

◦ Wear and Maintenance: Ensure the bearing cavity is clean and lubricated with the correct type and sufficient amount of grease. Overheating and abnormal noise are signs of bearing damage.

3. Support and Lubrication System

• Frame:

◦ Function: The backbone of the equipment, supporting all other components. It requires extremely high rigidity and strength.

◦ Maintenance: Regularly check for cracks and ensure that connecting bolts are tight.

• Spherical Bearing:

◦ Function: Located at the bottom of the moving cone, it supports the moving cone and main shaft while allowing the moving cone to oscillate.

◦ Wear and Maintenance: Lubrication is crucial. A lack of oil will rapidly cause wear and deformation, affecting the crusher's normal operation.

• Lubrication System:

◦ Function: Includes the oil pump, oil tank, cooler, filter, and piping. It provides lubrication and cooling for the gears, bearings, and bushings.

◦ Maintenance: This is the lifeline of the crusher. The oil level, oil temperature, and oil pressure must be checked regularly, and the lubricating oil and filter element must be replaced. If the oil temperature is too high or the oil pressure is abnormal, the machine should be shut down immediately for inspection.

4. Adjustment and Locking System:

Used to control the size of the discharge opening, thereby adjusting the product particle size.

• Adjustment Ring:

◦ Function: Located in the upper frame, it houses the fixed concave liner. Rotating the adjustment ring raises or lowers the fixed concave assembly, changing the size of the discharge opening.

◦ Maintenance: The threads on the adjusting ring are prone to dust accumulation and wear. Thoroughly clean and lubricate them before adjustment.

• Locking Cylinder and Locking Nut:

Function: After adjusting the discharge opening, the hydraulic locking cylinder and locking nut securely lock the adjusting ring to the machine frame to prevent loosening during operation.

Maintenance: Regularly check the hydraulic locking cylinder for normal pressure and the locking nut for tightness.

5. Dust Control System

• Dust Seal:

Function: Prevents dust from entering the lubrication system and protects precision components such as the eccentric sleeve and bushing.

Maintenance: Regularly inspect seals for aging and damage. Seal failure is one of the main causes of lubricant contamination and internal wear of the equipment.

II. Wear Parts List and Replacement Cycle

The lifespan of wear parts is significantly affected by material hardness, abrasiveness, feed conditions, and maintenance level. The following is a rough guide:

| Part Name | Expected Lifespan (Hours) | Key Replacement Indicators |

| Moving Cone Liner | 500 - 2000+ | Decreased production, product grains too coarse |

| Stationary Cone Liner | 500 - 2000+ | Used in conjunction with the moving cone liner; replacement is recommended in pairs |

| Spherical Bearing Shell | 3000 - 6000+ | Check wear pit depth; replace if exceeded |

| Eccentric Bronze Bushing | 5000 - 10000+ | Excessive clearance, abnormal lubrication pressure |

| Gears | 5000 - 10000+ | Tooth wear exceeding 10%, severe pitting |

| Dust Seal | 6 - 12 months | Regular preventive replacement to prevent further damage |

III. Daily Maintenance and Inspection Points

1. Pre-Startup Inspection: Check fasteners, V-belt tension, oil level, and foreign matter in all parts.

2. In-Operation Monitoring: Listen for abnormal vibration and noise; monitor oil temperature (usually no more than 55°C), oil level, and oil pressure; and observe whether the motor current is normal.

3. Regular Maintenance:

◦ Daily: Check for leaks and clean dust.

◦ Weekly/Monthly: Check for liner wear and clean the lubrication system filter.

◦ Semi-annually/Annually: Perform a comprehensive inspection, change the lubricant, and check the clearance and wear of core internal components (such as bushings and bearings).

IV. Parts Purchasing Recommendations

• Original Parts: Precise dimensions, high-quality materials, guaranteed performance and lifespan, but higher price.

• Certified Compatible Parts: Produced by third-party manufacturers, they meet original equipment manufacturer standards and offer a high cost-effectiveness, making them a common choice.

• Standard Compatible Parts: The lowest price, but quality and lifespan vary, and there is some risk.

Selection Recommendations: For core wear parts (such as liners) and critical structural components (such as the main shaft), we recommend using genuine original equipment manufacturers or high-quality certified compatible parts. For standard parts (such as seals and bearings), choose reliable brand-name products.

A thorough understanding of Simmons cone crusher parts is the foundation for preventive maintenance rather than after-the-fact repairs. A systematic parts management strategy, including regular inspections, proper lubrication, and the use of high-quality spare parts, maximizes equipment life, improves production efficiency, and reduces operating costs per ton of product.