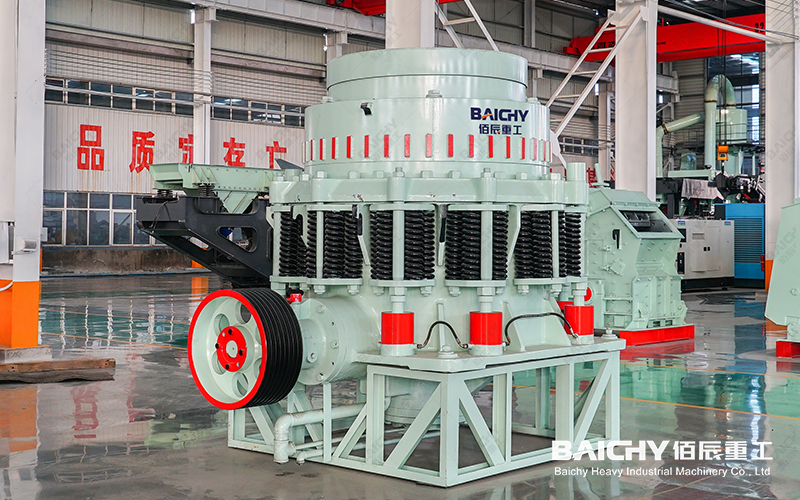

Symons 4ft Cone Crusher

Symons 4-foot cone crushers, classic equipment in the mining industry, continue to play a vital role in medium and fine crushing in numerous mines and quarries worldwide due to their robust structure, stable performance, and wide applicability. Their large installed base and long service life create a continuous and stable demand for spare parts.

Common vulnerable parts of cone crushers

Major consumables include:

• Wear parts: mantle, crushing wall (moving cone liner), bowl bearing, feed plate, etc.

• Core components: main shaft, sleeve, eccentric sleeve, gears.

• Seals and fasteners: various sizes of sealing rings, locking cylinders, bolts, etc.

Ensuring the timely supply of these spare parts is the lifeline for the continuous and efficient operation of the equipment.

Our core strengths: Why we are the ideal choice for Canadian customers

To meet the needs of Canadian customers, we leverage 20 years of experience to provide solutions that exceed expectations.

1. Global Inventory and Strategic Warehousing

We not only have central warehouses in Asia, but also strategic partner inventory points in North America (including neighboring regions of Canada). This means that when you need Symons 4-foot cone crusher parts, we can achieve rapid local allocation, reducing delivery times from weeks to days, significantly minimizing your downtime.

2. Superior Manufacturing and Quality Assurance

We are not simply a trading company. As a manufacturer, we possess a full set of advanced production equipment and a rigorous quality control system, with complete control over the entire process from high-manganese steel casting to precision machining. Our spare parts inventory strictly meets or exceeds original equipment manufacturer (OEM) standards in terms of materials, heat treatment processes, and dimensional accuracy, ensuring a perfect match with your equipment and a guaranteed service life.

3. In-depth Technical Understanding and One-Stop Service

20 years of industry experience have given us expertise in the technical details of various cone crushers. We can provide you with precise spare parts selection advice, wear problem diagnosis, and installation guidance, offering a one-stop purchasing experience from inpidual parts to complete wear parts packages, giving you peace of mind.

Cone crusher crushing site collection

Success Story: Trust Across Borders

A stone producer in British Columbia, Canada, experienced abnormal wear on the eccentric sleeve of a Symons 4ft cone crusher on its critical production line. Local suppliers offered high prices and had lead times of up to 8 weeks. After finding us through an industry referral, we precisely matched our inventory based on the equipment's serial number and shipped directly from our North American partner warehouse. The parts were delivered to the site within 5 business days, along with detailed installation instructions. The equipment quickly returned to production, and its efficiency was restored to normal. The client highly praised our responsiveness and technical expertise regarding spare parts inventory.

Related Spare Parts Recommendations

While searching for core spare parts inventory, we recommend considering checking or stocking the following high-value consumable parts to plan a more economical maintenance schedule:

• Symons 4ft Cone Crusher Wear Parts Kit: Includes matching mantle and crusher walls to ensure optimal crushing chamber shape and efficiency.

• Spindle Assembly Maintenance Kit: Includes spindle sleeves, seals, and critical fasteners for preventative overhauls.

• Hydraulic locking and clearing system accessories: Ensure sensitive and reliable equipment adjustment and protection.

Frequently Asked Questions (FAQ)

1. How can I ensure that the accessories I receive are a perfect match for my equipment?

A: Please provide your equipment's nameplate information (such as model number, serial number) or detailed drawings/photos of the original accessories. Our technical team will verify through a professional database to ensure that the accessories are 100% compatible in terms of dimensions, thread specifications, and tolerances. We can also provide samples for trial assembly confirmation.

2. How are the logistics and customs clearance handled for accessories shipped to Canada?

A: We have extensive experience exporting to Canada. We typically handle the transportation of accessories to designated Canadian ports (such as Vancouver and Toronto) and provide all necessary customs clearance documents, including commercial invoices, packing lists, and certificates of origin. We will recommend partner customs clearance agents or assist your customs clearance agent in completing the process to ensure smooth customs clearance.

3. How does the quality of your accessories compare to original parts?

A: Our parts are made of equal or superior materials (such as ultra-high manganese steel and alloy steel) and utilize advanced casting and heat treatment processes. While ensuring performance and lifespan, we offer more competitive prices. Feedback from numerous long-term Canadian customers confirms that our parts excel in wear life and equipment operational stability, making them a highly reliable and cost-effective choice.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!