Stone Crushing Plant Unit

As a company with 20 years of experience in the manufacturing of mining crushing equipment, we deeply understand that the crusher unit is the heart of the entire crushing production line. Its performance directly determines the efficiency, finished product quality, and operating costs of the entire production line. However, this core concept may still be unclear to many industry newcomers or purchasers. This article will delve into what a crusher unit is, its key components, type selection, and maintenance points, providing you with a comprehensive guide.

I. What is a Crusher Unit? Core Definition Explained

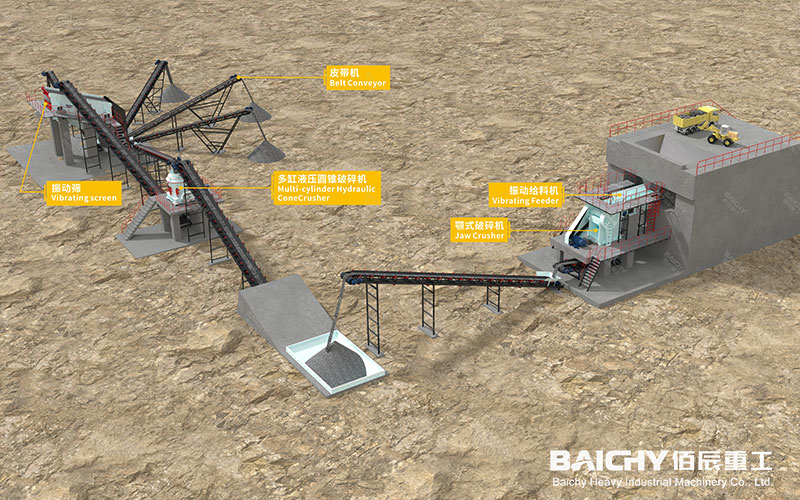

Simply put, a crusher unit is not just an isolated crusher. It is an integrated functional module, typically centered around a main crusher (such as a jaw crusher, cone crusher, impact crusher, etc.), and integrating feeding, conveying, power drive, control system, and auxiliary devices such as initial screening or iron removal. It is the workstation for primary or critical stage crushing of materials.

Its design goal is to ensure that crushing operations can be carried out efficiently, stably, and continuously, and to easily connect with downstream screening and conveying systems.

II. Core Components of a Crushing Unit

A complete crushing unit typically includes the following key components, which work together and are indispensable:

| Component Category | Main Components | Functions and Roles |

| Core Machine | Jaw Crusher, Cone Crusher, Impact Crusher, Hammer Crusher, etc. | The core equipment that applies mechanical force to the material to achieve crushing. |

| Feeding System | Vibrating Feeder, Heavy-Duty Plate Feeder | Evenly and controllably feeds raw materials into the main machine, preventing blockages and overload. |

| Drive System | Motor, Pulleys, V-Belts, Hydraulic Coupler, Reducer | Provides power to the crusher and transmits and regulates torque. |

| Discharge System | Discharge Conveyor Belt, Chute | Transports the crushed material out and guides it to the next processing stage. |

| Steel Structure and Frame | Main machine frame, feeder support, platform ladder | Supports all equipment, ensuring overall stability and rigidity. |

| Control System | Electrical Control Cabinet, PLC, Sensors (Current, Temperature, Vibration) | Control unit starts/stops, monitors operating status, and provides overload protection. |

| Auxiliary Equipment | Magnetic Remover, Pre-screening Grating, Buffer Silo, Dust Collection Interface | Removes impurities, pre-screens, ensures continuous material supply, and controls dust. |

III. Types and Application Scenarios of Main Crusher Units

PE Jaw Crusher

Hydraulic Cone Crusher

Depending on the core host machine, the types and applicable scenarios of crusher units vary significantly. Correct selection is key to success.

| Unit Type | Core Host Machine | Crushing Principle | Applicable Materials | Typical Discharge Particle Size | Application Scenarios |

| Coarse Crushing Unit | Jaw Crusher | Extrusion Crushing | High-hardness ore (Granite, Basalt), Construction Waste | 100-350mm | First-stage crushing in mines and quarries, processing large raw materials. |

| Medium Crushing Unit | Cone Crusher | Lamination Extrusion | Medium-to-high hardness ore | 20-100mm | Secondary crushing, pursuing stable output and high wear resistance, commonly used in aggregate production lines. |

| Medium and Fine Crushing Unit | Impact Crusher | Impact Crusher | Medium and Low Hardness Ores (Limestone, Dolomite), Construction Waste | 0-40mm (Adjustable) | Secondary or Tertiary Crushing, Good Finished Particle Shape, Commonly Used in Building Materials and Recycling Industries. |

| Sand Making Unit | Vertical Shaft Impact Crusher (Sand Making Machine) | Centrifugal Impact, Stone-on-Stone/Iron | Various Rocks | Tailings 0-5mm (Adjustable) | Specialized in producing high-quality manufactured sand for concrete and asphalt mixing plants. |

20 Years of Experience Tip: When selecting a crusher, it is necessary to comprehensively consider the material hardness, abrasiveness, feed particle size, required output, and finished product shape requirements. System planning by a professional engineer is usually required.

IV. How to Select and Optimize Your Crushing Unit?

Selecting a suitable crushing unit is a systematic project. Based on our 20 years of service experience, we suggest you evaluate it from the following dimensions:

1. Material Characteristic Analysis: This is the first step. Material testing is essential to determine its compressive strength, silicon content, moisture content, viscosity, etc.

2. Production Capacity and Particle Size Matching: Clearly define your hourly/annual production targets and the gradation requirements of your final product (e.g., aggregate).

3. Overall Layout and Investment: Consider the size of the installation site, power configuration, and the balance between initial investment and long-term operating costs. A compact and easy-to-maintain unit can significantly reduce later costs.

4. Manufacturer's Technical Strength and Service: Assess the manufacturer's experience with similar projects, their ability to provide full-process support from design, installation to commissioning and training, and the timeliness of spare parts supply.

Optimization Directions:

• Automation Upgrade: Add intelligent sensors and control systems to achieve remote monitoring, fault warning, and automatic feed adjustment, improving efficiency and safety.

• Wear Part Optimization: Use higher-performance alloy materials (such as ultra-high manganese steel and ceramic composites) to manufacture wear parts, extending replacement cycles.

• Environmental Protection and Noise Reduction: Integrate sealed covers and high-efficiency dust removal points, and equip with sound insulation materials to meet environmental protection requirements.

V. The Cornerstone of an Excellent Unit: Maintenance and Care

Even the most advanced equipment requires meticulous maintenance. Establishing a preventative maintenance plan is crucial:

• Daily Inspection: Check fasteners, bearing temperature, abnormal noises, and belt tension.

• Regular Maintenance: Replenish or replace lubricating grease on time (especially for the cone crusher's main shaft bearings), and check the wear condition of wear parts.

• Data Recording: Record operating current, output, and replacement time of vulnerable parts; use data analysis to predict equipment status.

The crushing unit is the cornerstone of mining and aggregate production; its importance is self-evident. Choosing a scientifically designed, reliable, and condition-matched crushing unit is a key first step in ensuring the long-term profitability of your project. As a manufacturer with 20 years of industry experience, we not only provide a variety of high-quality crushing units, from single machines to complete systems, but also offer professional solutions and full lifecycle service support.