In industries such as glass manufacturing, casting, and photovoltaic materials, the purity and moisture content of silica sand (quartz sand) directly determine the quality of the final product. Wet sand not only causes clumping and blockage of the feed inlet, but also severely affects the melting effect and mold precision. How to efficiently and stably control the moisture content of silica sand? A high-performance silica sand dryer is undoubtedly a crucial link in the production line. This article will provide you with a comprehensive understanding of silica sand dryers to help you make an informed choice.

I. How Does a Silica Sand Dryer Work?

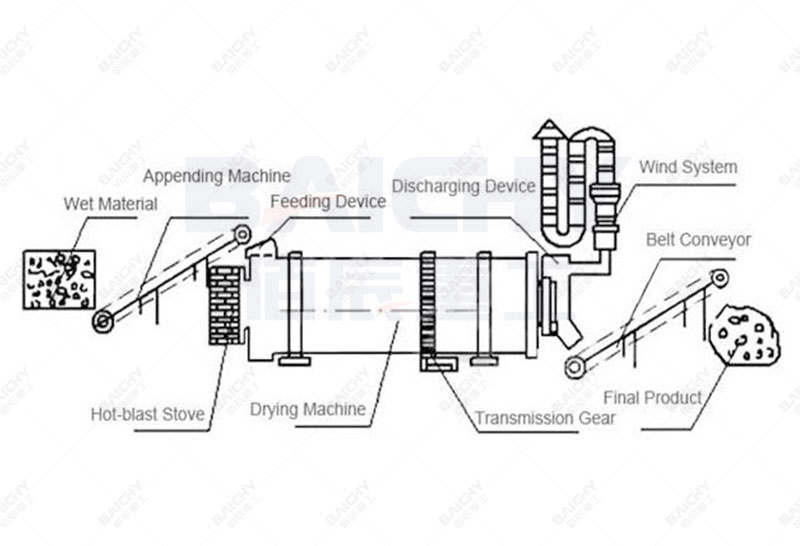

Currently, the most mainstream and efficient silica sand dryers on the market use drum drying technology. Its working principle can be summarized in the following steps:

1. Feeding and Lifting: After dehydration, the wet silica sand is fed into the drum by a belt conveyor. The inner wall of the drum is equipped with specially designed lifting plates. As the drum rotates at a uniform speed, the lifting plates continuously scoop up and sprinkle the sand.

2. Hot Air Contact: High-temperature, pure hot air from a heat source (such as a gas-fired hot air furnace, coal-fired furnace, or biomass furnace) exchanges heat thoroughly and efficiently with the sand falling in a waterfall-like manner inside the drum.

3. Moisture Evaporation: Under high temperature and thorough contact, the moisture on the surface of the silica sand particles is rapidly evaporated.

4. Separation and Discharge: The evaporated water vapor is extracted by the exhaust fan at the tail end, while the dried silica sand is discharged through the discharge end, completing the entire drying process.

This "drum lifting" design ensures that each grain of sand is heated evenly, avoiding under-drying or over-drying, resulting in extremely high efficiency.

II. How to Choose? A Key Comparison of Two Mainstream Models

Faced with different manufacturers' claims, which type of dryer is most suitable? The following is a comparison of two mainstream structures:

Single-Drum Dryer:

◦ Structure: A relatively long rotating cylinder, simple structure.

◦ Advantages: Mature technology, stable operation, convenient maintenance, and relatively low investment cost.

• Disadvantages: Slightly larger footprint, relatively lower thermal efficiency, and greater heat loss.

• Suitable for: Small to medium-sized projects or users with limited budgets who are not very sensitive to energy consumption.

Three-pass rotary dryer (recommended first choice):

• Structure: Consists of three concentric nested cylinders. Sand passes through the inner, middle, and outer cylinders sequentially, resulting in a longer travel path.

• Advantages: High efficiency and energy saving are the biggest highlights. The cylinders are insulated layer by layer, resulting in extremely high thermal energy utilization, saving up to 20%-40% more coal than a single-cylinder dryer. Small footprint and good environmental performance.

• Disadvantages: Relatively complex structure and slightly higher manufacturing cost.

• Suitable for: Suitable for large and medium-sized production lines that require low operating costs, high output, and strict environmental protection requirements. It is currently the mainstream and preferred solution in the market.

III. Five Key Factors Determining Your Return on Investment

When choosing a silica sand dryer, do not focus solely on price. Consider the following points comprehensively:

1. Initial Moisture Content and Target Moisture Content: Clearly define your sand's moisture requirements before and after drying. This is the foundation for equipment selection.

2. Hourly/Daily Output Requirements: Select a model that matches your production scale to avoid underutilization or idle resources.

3. Heat Source Selection: Choose a heat source such as natural gas, oil, coal, or biomass pellets based on local environmental policies and fuel costs.

4. Equipment Materials and Manufacturing Processes: The core rollers and lifting plates must be made of wear-resistant and high-temperature-resistant materials, directly affecting the equipment's lifespan.

5. Manufacturer Strength and After-Sales Service: Choosing a professional silica sand dryer manufacturer with strong technical capabilities and extensive experience ensures equipment quality and timely technical support.

IV. About Price: How much does a silica sand dryer cost?

This is one of the most pressing questions for users. The price of a silica sand dryer is not fixed and is influenced by various factors, including model specifications (5 tons, 10 tons, 20 tons per hour, etc.), technical configuration (three-pass dryers are more expensive than single-drum dryers), heat source solutions, and customized requirements. Small equipment may start at tens of thousands of yuan, while large automated production lines can cost millions of yuan. The wisest approach is to provide the manufacturer with your specific needs to obtain a tailored solution and quote.

Choosing the right silica sand dryer is a significant investment affecting product quality, production efficiency, and long-term operating costs. This guide aims to clear up any confusion and provide a clear understanding from principles to model selection.

If you are looking for solutions to silica sand moisture problems, please contact us. As a professional silica sand dryer manufacturer, we are happy to provide you with free technical consultation and customized solutions to help you build a highly efficient and energy-saving drying production line!