In industries like wood processing and furniture manufacturing, large quantities of sawdust and wood chips were once considered a burdensome waste. However, with the rise of biomass energy, this "waste" has been transformed into valuable raw materials for manufacturing wood pellet fuel, charcoal, and wood-based panels. The core equipment enabling this remarkable transformation is the sawdust dryer. This article will provide you with an in-depth understanding of sawdust dryers, offering comprehensive guidance for your selection and use.

I. Why Must Sawdust Be Dryed?

Freshly produced sawdust typically contains 30%-50% or even higher moisture content. High humidity leads to a series of problems:

• Affects molding: Excessive moisture makes it difficult to press wood pellets, charcoal, and other products into shape, or they are prone to loosening and cracking.

• Reduces calorific value: Moisture consumes a large amount of heat during combustion, severely impacting the thermal efficiency of biomass fuels.

• Causes mold growth: Damp sawdust is difficult to store, easily molds and deteriorates, resulting in losses.

Therefore, reducing the moisture content of sawdust to below 10%-15% using a dryer is a crucial step in maximizing its utilization value.

II. How Does a Sawdust Dryer Work? (Taking the Mainstream Rotary Drum Type as an Example)

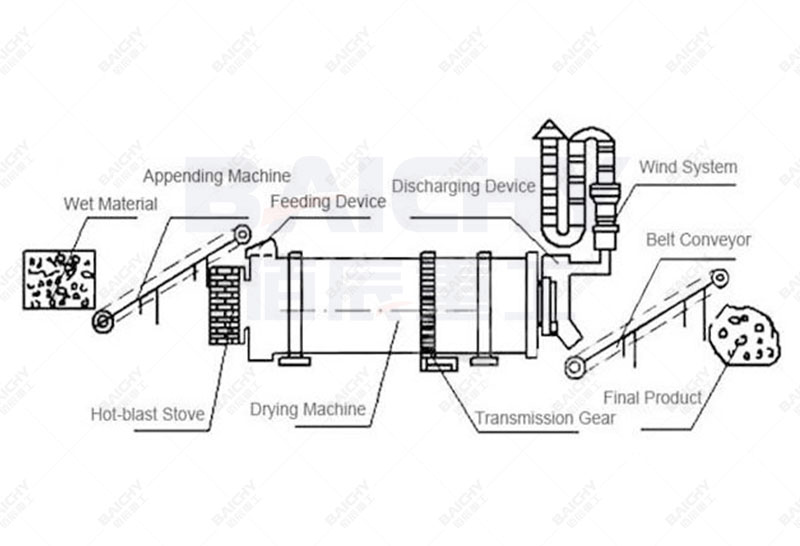

Currently, the most widely used type is the single-channel or three-channel rotary drum dryer. Its workflow can be simplified to three steps: "feeding, drying, and discharging":

1. Feeding: Wet sawdust is fed into the continuously rotating drum by a conveyor.

2. Drying: The drum is equipped with lifting plates that continuously lift and scatter the sawdust, ensuring it comes into full contact with hot air (provided by a hot air furnace) and rapidly evaporates moisture.

3. Discharging: The dried sawdust is collected at the end of the drum, and the exhaust gas is purified by a dust removal system before being discharged.

The entire process is continuous, featuring large processing capacity, uniform drying, and high thermal efficiency.

III. What are the Common Types of Sawdust Dryers?

1. Rotary Drum Dryer: The mainstream type in the market, suitable for large-scale, continuous production, with stable and reliable performance.

2. Airflow Dryer: Utilizes high-speed hot air to instantly dry and convey materials. Suitable for sawdust with fine particles and low moisture content. Lower investment is required.

3. Box-type Dryer (Belt Dryer): Suitable for small-batch, multi-variety production. Flexible operation, but relatively low efficiency.

IV. Key Considerations When Purchasing a Sawdust Dryer

• Processing Capacity: Select the appropriate model based on your daily processing capacity (tons/day).

• Initial Moisture Content and Final Moisture Content: Determine the moisture content of your raw materials and the target drying moisture content.

• Heat Source Selection: Gas, oil, biomass pellets, steam, or electricity can be used. The choice should be based on local energy costs and environmental requirements.

• Equipment Material and Insulation: High-quality steel and good insulation extend equipment life and significantly reduce heat loss.

• Environmental Standards: Ensure the equipment is equipped with a high-efficiency dust removal system (such as cyclone dust collector + bag filter) to meet emission requirements.

V. What Factors Affect the Price of Sawdust Dryers?

The price of sawdust dryers ranges from tens of thousands to hundreds of thousands or even millions of yuan, mainly influenced by factors such as model specifications, processing capacity, level of automation, brand, and after-sales service. It is recommended to contact multiple suppliers and provide specific requirements to obtain accurate quotes.

A high-efficiency, energy-saving sawdust dryer is not only a tool for waste disposal but also a "profit amplifier" for creating economic value for you. Through scientific selection and correct use, you can transform inexpensive sawdust into high-value-added green products, achieving a win-win situation for both environmental protection and economic benefits.