Spiral Sand Washer: An Efficient Solution for Sand and Gravel Cleaning

In the construction, mining, concrete and other industries, the cleanliness of sand and gravel directly affects the quality of the finished product. As the core equipment of the gravel cleaning system, the spiral sand washer has become the preferred solution for sand and gravel cleaning due to its high efficiency, energy saving and durability.

Advantages of Spiral Sand Washer

✔ Efficient cleaning: The spiral blades are used for tumbling and stirring to ensure that the sand and gravel are fully cleaned, with a cleaning rate of more than 95%.

✔ Energy saving and environmental protection: Low energy consumption design, water resource recycling, and reduced sewage discharge.

✔ Strong structure: Made of wear-resistant materials, suitable for high-intensity operations, and long service life.

✔ Strong processing capacity: 6-400 tons of sand and gravel can be processed per hour to meet the production needs of different scales.

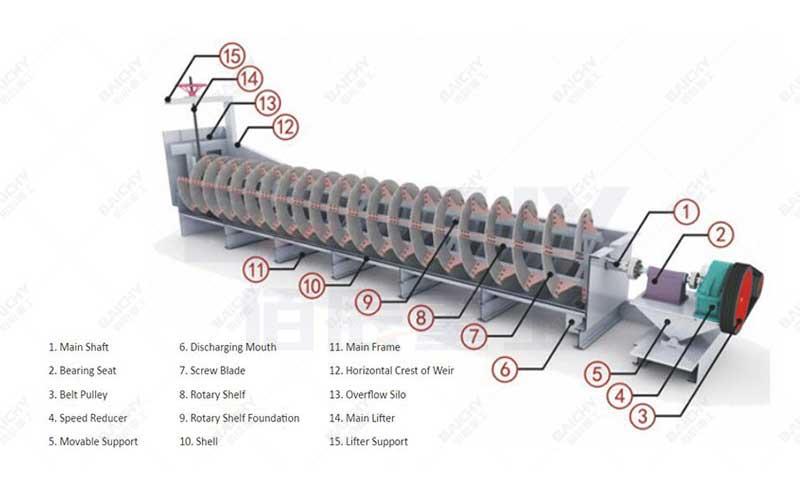

Working principle of spiral sand washing machine

The spiral sand washing machine drives the sand and gravel to roll in the tank body through the rotation of the spiral shaft, and at the same time, the water flow is flushed to separate the soil, impurities and sand and gravel. The cleaned sand and gravel are discharged from the discharge port, and the sewage is recycled through the sedimentation tank or filtration system.

Applicable materials:

• Natural sand, machine-made sand

• Gravel, pebbles

• Mine tailings, construction waste

Spiral sand washing machine vs. bucket sand washing machine: How to choose?

| Comparison items | Spiral sand washing machine | Bucket sand washing machine |

| Cleaning effect | High cleaning rate, suitable for fine cleaning | Suitable for simple cleaning |

| Processing capacity | Large (6-400 tons/hour) | Small (30-160 tons/hour) |

| Energy consumption | Low | High |

| Floor space | Large | Small |

| Applicable scenarios | Large sand and gravel plants, mines | Small production lines, temporary operations |

Conclusion:

If you pursue high cleaning rate and large output, spiral sand washing machine is better.

If the site is limited or the cleaning requirements are not high, bucket sand washing machine is more economical.

How to choose a suitable gravel cleaning system?

Determine the production demand: select the matching spiral sand washing machine model according to the scale of the production line.

Investigate the characteristics of sand and gravel: materials with high mud content require enhanced cleaning structure.

Focus on energy consumption and environmental protection: choose energy-saving design to reduce operating costs.

Manufacturer service: give priority to regular manufacturers that provide installation, commissioning and after-sales maintenance.

The spiral sand washing machine is the core equipment of the gravel washing system, which directly affects the quality of sand and gravel and production efficiency. Choosing the right model can not only improve the cleaning rate, but also reduce operating costs. If you are looking for an efficient and durable sand washing machine, please contact us for professional solutions!