Professional Rotary Dryer Manufacturer | High-Efficiency and Energy-Saving Solutions

Rotary dryers are key equipment used in mining, metallurgy, chemical, and other industries for processing large quantities of bulk wet materials. As a manufacturer of mining crushing equipment with 20 years of experience, we deeply understand the importance of the material drying process in the production flow. It not only affects the efficiency of subsequent processes but also directly impacts the quality of the final product and energy consumption costs. In the current industry context emphasizing green production and cost control, choosing an efficient, reliable, and energy-saving rotary dryer is one of the key decisions to enhance a company's overall competitiveness.

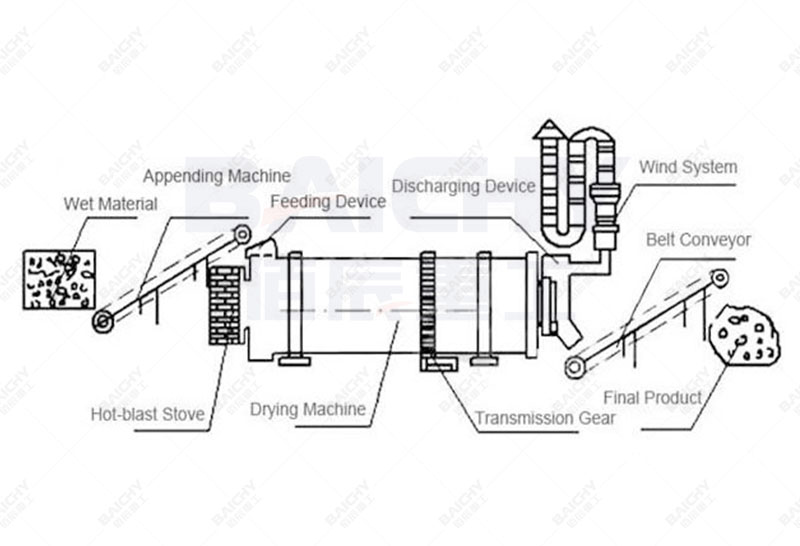

A rotary dryer, also known as a drum dryer, is a large-scale continuous drying equipment that uses a tilted rotating drum to allow wet materials to fully contact with hot air inside the drum, thereby achieving the purpose of evaporating moisture and drying the materials. Its core working component is a slightly inclined and rotating cylinder. Wet materials are fed in from the high end, and as the cylinder rotates, the materials flow to the low end under the action of gravity. During this process, the materials are repeatedly lifted and scattered by the lifting plates inside the cylinder, undergoing sufficient heat exchange with the co-current or counter-current hot air (or hot flue gas). Moisture is quickly removed, and the dry materials are discharged from the low end.

With 20 years of technological accumulation and project experience, our rotary dryers are at the industry-leading level in terms of thermal efficiency, processing capacity, reliability, and adaptability. We can customize solutions for our customers, from single machines to complete drying production lines.

Dryer structural diagram

Core Advantages of Rotary Dryers

1. Large processing capacity and high drying intensity: The equipment has a large cylinder volume, allowing a large amount of material to pass through continuously. The unique internal lifting plate design greatly increases the contact area between the material and the heat medium, resulting in high heat and mass transfer efficiency and strong drying capacity per unit volume.

2. Stable operation and simple operation: The structure is robust and reasonably designed, with a low failure rate, allowing for 24-hour continuous and stable operation. It features a high degree of automation, making operation and maintenance simple and convenient, and reducing labor costs.

3. Strong adaptability and uniform drying: By adjusting parameters such as rotation speed, inclination angle, hot air temperature, and flow rate, it can easily adapt to materials with different initial moisture content, particle size, and thermal characteristics (such as mineral powder, coal powder, sand, clay, etc.). The materials are repeatedly lifted and scattered inside the cylinder, resulting in high drying uniformity.

4. Flexible heat source selection, energy-saving and environmentally friendly: Depending on customer conditions, the system can be flexibly equipped with coal-fired, gas-fired, or oil-fired hot air furnaces, or utilize waste heat as a heat source. Optimized insulation design and exhaust gas treatment systems effectively reduce heat loss, lower energy consumption, and meet environmental emission requirements.

5. Robust and durable, long lifespan: As a professional mining equipment manufacturer, we use high-quality wear-resistant steel plates and key components to ensure the durability of the equipment under harsh working conditions, with a service life far exceeding the industry average.

Actual shot of Malaysias tin ore drying production line

Successful Application Case

One of our large rotary dryers was successfully applied in a large iron ore beneficiation plant in Central China. The plant needed to dewater and dry the iron concentrate after flotation for easier transportation and storage.

Customer Challenge: Large processing capacity (30 tons per hour required), initial moisture content of approximately 15%, requiring a final moisture content below 8%, and limited on-site space, with strict requirements for equipment stability and energy consumption.

Our Solution: We customized a rotary dryer with a diameter of 2.8 meters and a length of 16 meters, using a counter-current heating method, and equipped with a gas-fired hot air furnace and a high-efficiency cyclone dust collector + wet scrubber system.

Operating Results: After three years of operation, the equipment has fully met and exceeded the design specifications, with the final moisture content consistently below 7%, high thermal efficiency, saving approximately 18% energy compared to the customer's original equipment, and operating smoothly with minimal maintenance, creating significant economic benefits for the customer.

Related Equipment Recommendations

A complete drying production line usually requires not only the rotary dryer main unit, but also supporting equipment to work together:

Feeding System: Belt conveyor, bucket elevator, quantitative feeder, ensuring uniform and continuous feeding.

Heat Source System: Biomass/gas/oil-fired hot air furnace, heat exchanger, providing a stable and efficient heat source.

Dust Removal System: Cyclone dust collector, bag filter, wet scrubber tower, purifying exhaust gas to meet environmental requirements.

Discharge and Conveying: Screw conveyor, scraper conveyor, transporting the dried material to the designated location. Intelligent Control System: Centralized electrical control cabinet for automatic monitoring and adjustment of temperature, rotation speed, and airflow.

We can provide turnkey engineering services from single machines to complete systems.

Frequently Asked Questions (FAQ)

Q1: Is a rotary dryer suitable for drying my material?

A: Rotary dryers have a wide range of applications, especially suitable for granular, lumpy, and flaky bulk materials that are not susceptible to abrasion. If you need to dry materials such as slag, sand, coal powder, fertilizers, or forage, it is usually an ideal choice. Specific suitability needs to be determined based on the initial moisture content, particle size, viscosity, heat resistance, and other characteristics of the material. Please contact us to provide material samples for professional analysis.

Q2: What is the energy consumption of the equipment? How can energy be saved?

A: Energy consumption is the main operating cost of a dryer. Our equipment achieves energy savings through the following methods: optimizing cylinder insulation to reduce heat loss; designing a reasonable lifting plate structure and airflow speed to improve heat exchange efficiency; configuring a hot air circulation system or waste heat recovery device; and providing precise automatic control to avoid over-drying. We will recommend the most economical energy solution based on your specific conditions.

Q3: How long does it usually take from placing an order to installation and operation?

A: The cycle depends on the specifications and customization level of the equipment. For standard models, the general production cycle is 30-45 days. Large non-standard customized equipment may require 60-90 days. We have a mature production system and supply chain and will do our best to shorten the delivery time. We also provide detailed installation instructions or dispatch engineers for on-site service to ensure rapid commissioning of the equipment.