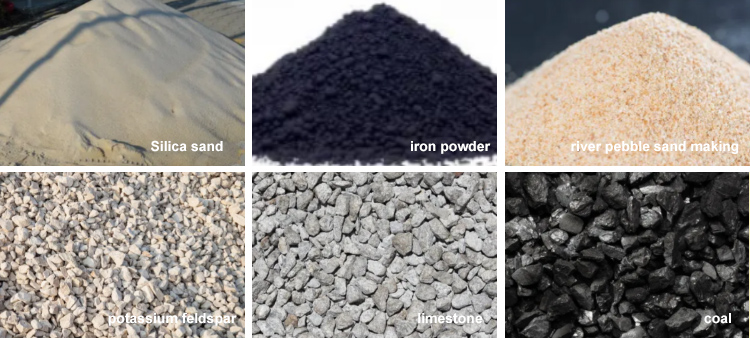

Roller crusher is widely used for fine or superfine crushing in the industries of mining, construction materials, metallurgy, chemical industries, and so on. It can crush all kinds of materials under middle hardness, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, chemical materials, and so on.

For example, to make silica sand from quartz or silica stone; crush iron ore into fine powder for iron ore beneficiation; make machine-made sand from cobblestone or building waste; do fine crushing of potash feldspar and soda feldspar for ceramic industry; do fine crushing of limestone for desulfurization in heat and electricity industry; to do pre-crushing of the cement raw materials before feeding into the mill, etc.

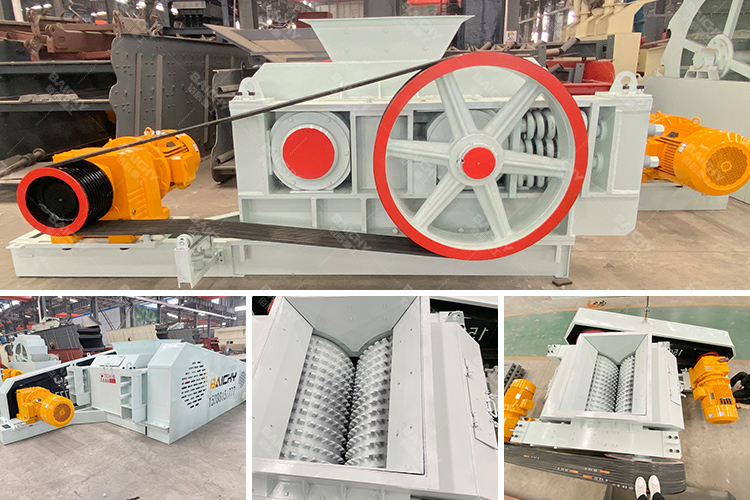

1. The roller is made of wear-resistant chromium-molybdenum-copper alloy and has been heat-treated multiple times, with a service life of 2000-8000 hours.

2. When the material is too hard or there is a material that is not easily broken, the driving roller will automatically retract under the action of the spring or hydraulic system to protect the machine from damage.

3. The roller gap is adjustable, thereby changing the discharging granularity and output.

4. The service life of the bearings exceeds 20,000 hours. Double seals are used inside and outside the bearing to replenish lubricating oil for a long time.

5. This crusher uses a non-powered distributor to distribute materials evenly into the crusher, ensuring good output particle size and protecting the roller surface from uneven wear.

6. The crusher is equipped with a motorless scraper. When the moisture content of the raw material is high, it can avoid affecting the output size and avoid sticking the roller or blocking the machine.

7. Operating at different speeds, the rollers clean each other to avoid raw material agglomeration.

8. The crusher works reliably and has a low failure rate, low noise, and low maintenance cost.

The working principle of roller crusher:

The working principle of the double-roller crusher: When the double-roller crusher works, the raw materials are fed and fall into the V-shaped crushing cavity between the two crushing rollers, and are subjected to the extrusion force and shearing force of the two co-rotating rollers. It is broken into qualified particle sizes and then discharged from the crusher.

Working principle of three-roller crusher: The three rollers adopt a staggered arrangement structure to form two crushing chambers. When the crusher is working, the material is first fed into the V-shaped crushing cavity of the two upper rollers, crushed by the extrusion and shearing force of the two counter-rotating rollers, and then falls into the second crushing cavity to be crushed. After the material is crushed twice, it is discharged from the discharge port.

Working principle of four-roller crusher: Four-roller and two crushing chambers. The four-roller crusher is divided into upper and lower parallel groups to form two independent crushing chambers. When the crusher is working, the material is fed into the V-shaped crushing chamber of the two upper rollers and crushed by the extrusion and shearing force of the two counter-rotating rollers. Then it falls into the crushing cavity of the two lower rollers and is crushed again. After the material is crushed twice, it is discharged from the discharge port.

Baichy Heavy Industrial Machinery Co., Ltd