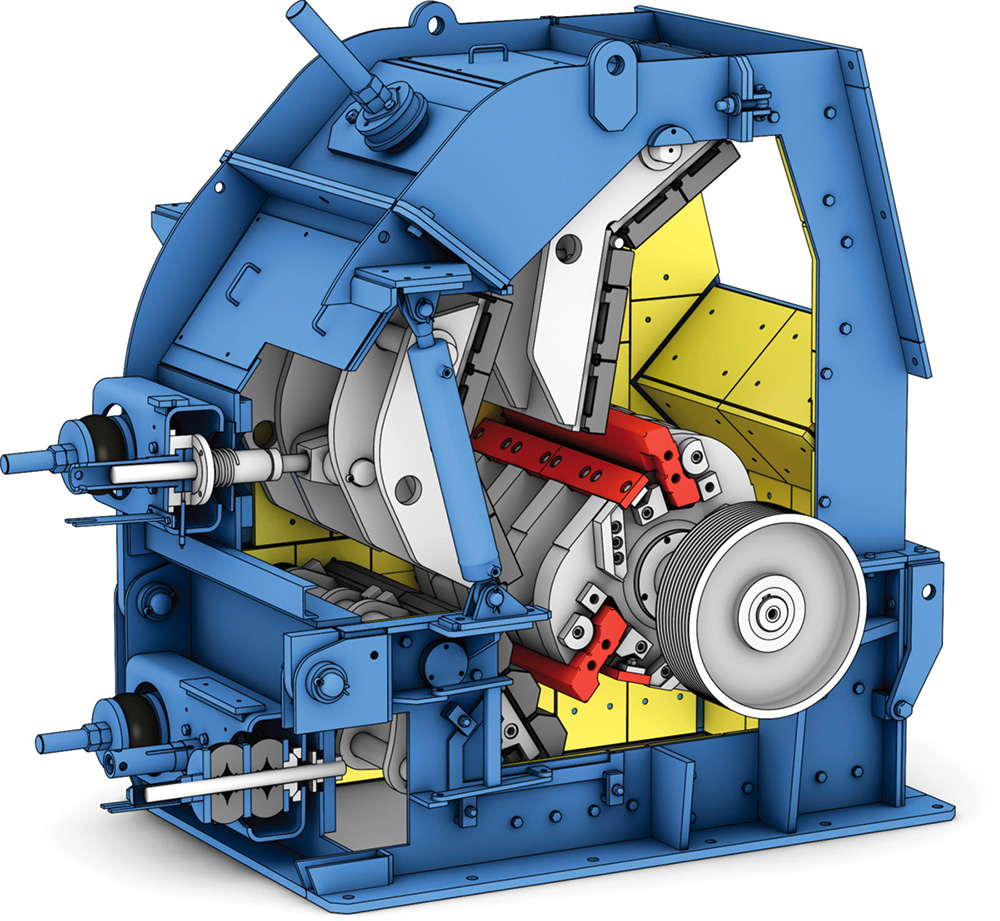

Powerful rotors

Sturdy welded structure

Wears parts can be replaced quickly

Quick and simple blow bar replacement thanks to patented mounting system

Available with several different rotor versions depending on application

Robust impact plates

Two versions: Monoblock casting, welded steel structure

Flexible configuration for any shredding application

Impact plates supported by durable, maintenance-free spring units

Large feed opening

Prevents material jams

Optimum use of crushing chamber even at maximum input size

High throughput rates

Excellent shredding results

Maintenance-friendly design

Durable, compact design

Easy access for maintenance thanks to two-piece enclosure

Optimized wear parts

Interchangeable parts reduce number of parts you need to keep in stock

Easy to replace

Monoblock casting

Impact crusher with monoblock casting baffle plates which can be rotated by 180°

Suitable for limestone and similar types of rock and for concrete recycling

Monoblock casting with wear strips

Impact crusher with monoblock casting baffle plates with screw-fastened wear strips made of white cast iron

Suitable for medium-hard rock

Welded construction with wear elements

Impact crusher with welded baffle plates and screw-fastened wear elements made of white cast iron.

Well suited for more abrasive types of rock.

Impact mill with additional grinding track

The additional grinding track located below the rotor axle is used to increase the crushing ratio, improve the particle shape and increase the crushed face count.

Alternative impact plates (see above) depending on the type of rock.