When selecting mining crushing equipment, many users often face a crucial decision: Can a double-roll crusher replace an impact crusher? Each type of equipment has its own unique characteristics and differs in its application scenarios. This article will provide an in-depth analysis of their operating principles, performance characteristics, and applicable areas to help you make an informed choice.

I. Working Principle Comparison

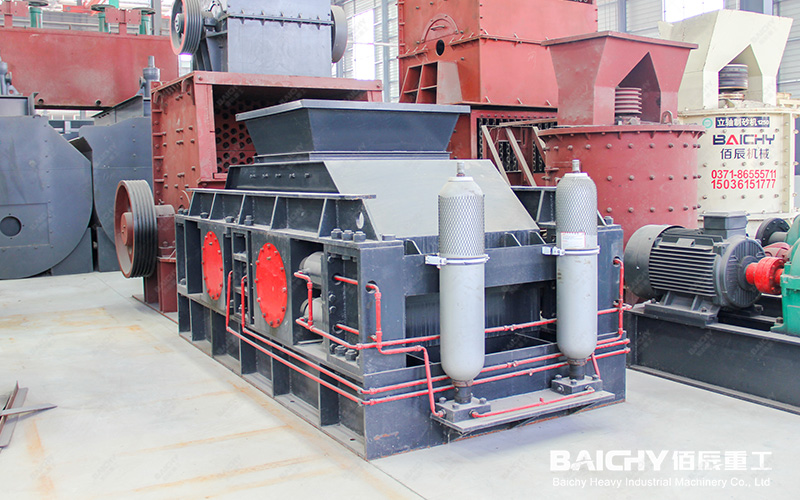

1. Double-roll Crusher Working Principle

Double-roll crusheruses two counter-rotating rollers to crush material. Material enters between the rollers from above, where it is crushed by the squeezing and shearing forces. Adjusting the gap between the rollers controls the output particle size.

Core Features:

• Extrusion Crushing Principle

• Adjustable Output Particle Size

• Simple Structure and Easy Maintenance

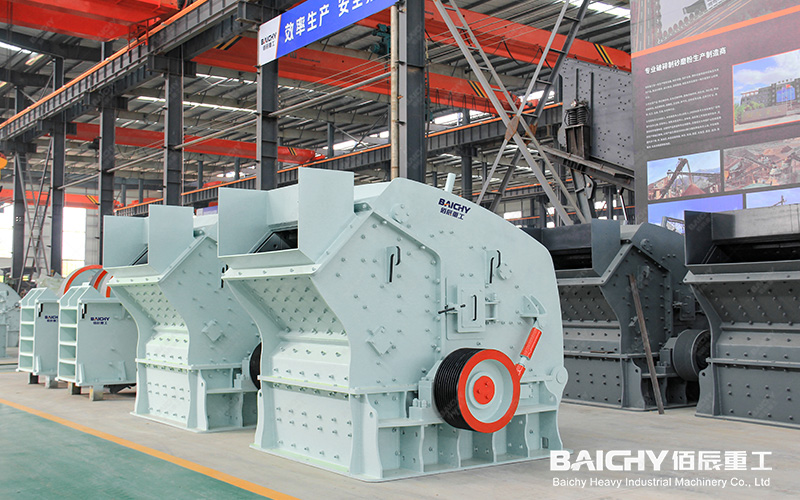

2. Impact Crusher Working Principle

Impact crusher uses a high-speed rotating rotor to drive hammers to strike the material, causing repeated impacts between the impact plates and hammers. The material undergoes multiple impact crushing cycles within the crushing chamber.

Core Features:

• Impact crushing principle

• Multi-stage crushing process

• Excellent product particle shape

II. Comprehensive comparison of performance parameters

| Comparison Items | Double Roller Crusher | Impact Crusher |

| Crushing Method | Extrusion Crushing | Impact Crushing |

| Output Particle Size | Relatively uniform, can be precisely controlled | Within a certain range of distribution |

| Processing Capacity | Medium | High |

| Energy Consumption | Low | High |

| Noise Level | Low | High |

| Maintenance Cost | Low | Medium |

| Applicable Hardness | Medium to below Hard Materials | Medium Hard Materials |

| Product Particle Shape | General | Many Cubic Particles, Good Particle Shape |

| Moisture Content Requirement | Can handle materials with high moisture content | Sensitive to moisture content |

| Metallic Foreign Matter | Relatively sensitive | Tolerant |

III. Application Scenarios

Double-roll crushers are more suitable for:

1. Applications requiring precise control of output particle size, such as coal and coke crushing

2. Processing of sticky and wet materials, such as clay and mudstone

3. Small and medium-sized production lines with low output requirements

4. Users with limited budgets seeking cost-effectiveness

5. Space-constrained sites where the double-roll crusher's compact structure is desirable

Impact crushers are more suitable for:

1. Aggregate production requiring fine particle shape, such as for commercial concrete mixing plants

2. Crushing of medium-hard materials, such as limestone and granite

3. Large-scale production lines with high output requirements

4. Secondary or fine crushing in multi-stage crushing systems

5. Where certain shaping functions are required

IV. Substitution Feasibility Analysis

Double-roll crushers can replace impact crushers under certain conditions, but the following factors should be considered:

1. Material Properties: For materials with a medium or lower hardness that do not require special shaping and have a high moisture content, double-roll crushers are a good alternative.

2. Product Requirements: If particle shape requirements are not high, double-roll crushers can meet the needs.

3. Cost Considerations: Double-roll crushers generally have lower purchase and maintenance costs.

4. System Compatibility: The compatibility of the entire crushing system should be evaluated.

Irreplaceable Situations:

• Processing high-hardness materials

• Requirement of excellent product particle shape

• Large-scale, high-output production lines

• Processes requiring multi-stage impact crushing

V. Selection Recommendations

1. Evaluate Material Properties: First, determine the material's hardness, moisture content, viscosity, and other characteristics.

2. Define Product Requirements: Determine specific requirements for output and particle size.

3. Consider long-term operating costs: This includes energy consumption, frequency of part replacement, etc.

4. Consult a professional engineer: Get targeted equipment selection advice.

5. On-site inspection: Visit a production site handling similar materials and observe the equipment in action.

VI. Maintenance and Optimization Recommendations

Regardless of the equipment selected, proper maintenance will extend its service life:

Key points for double-roll crusher maintenance:

• Regularly check roller wear

• Maintain parallelism between the rollers

• Promptly remove adhering material

• Regularly maintain the lubrication system

Key points for impact crusher maintenance:

• Regularly check hammer wear

• Maintain the flexibility of the impact plate adjustment system

• Check rotor dynamic balance

• Monitor bearing temperature

VII. Future Development Trends

With technological advancements, both types of equipment are continuously evolving:

1. Double-roll crushers are becoming larger and more intelligent, and the use of new wear-resistant materials has extended their service life.

2. Impact crushers have made progress in energy conservation, consumption reduction, and automated control, resulting in continuously improved crushing efficiency.

3. New compound crusher models combining the advantages of both are under development.

Double-roll crushers and impact crushers each have their own advantages and disadvantages, and whether they can be interchanged depends on specific operating conditions. For small- to medium-sized projects processing low- to medium-hardness materials with minimal requirements for particle shape, a double-roll crusher is a cost-effective and practical choice. However, for large-scale production lines, crushing high-hardness materials, or applications requiring high particle shape, an impact crusher remains the preferred choice. Before selecting a crusher, we recommend fully understanding the material characteristics and production requirements, and consulting a professional crushing equipment supplier if necessary to ensure the most suitable crushing solution.

Regardless of the equipment ultimately chosen, proper operation and maintenance are crucial to ensuring efficient operation and extending its service life. We hope this article provides valuable guidance for your crushing equipment selection process.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)