BAICHY Crushing and Screening Technology serves all industries involved in the size reduction of rock and minerals, meeting your specific requirements from single to mobile plants and complete rock processing plants, all supported by highly efficient after-sales service.

There are many types of crushing equipment, common ones include:

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.

FAQ about rock crushing and screening plant

1. What is the main function of a rock crushing and screening plant?

Blocks of rock are processed into aggregates of different specifications (such as gravel, sand, etc.) through crushing, screening, and other processes for construction, roads, concrete, and other projects.

2. What is the basic process of crushing and screening?

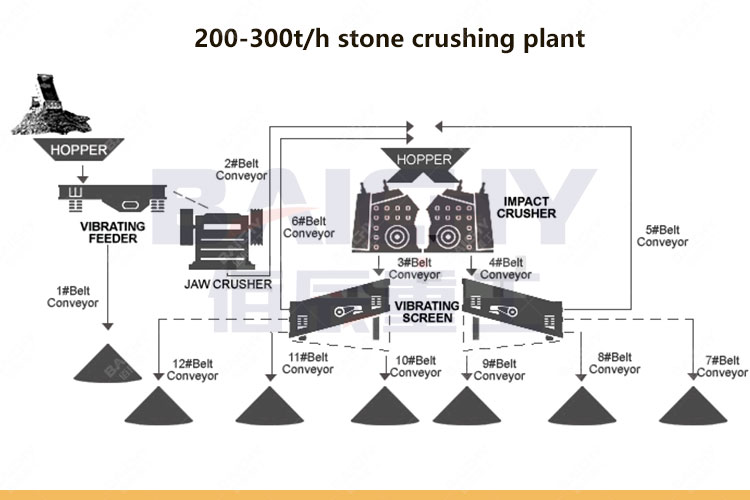

• Coarse crushing: Jaw crusher crushes large rocks into medium particles.

• Medium and fine crushing: Cone crusher or impact crusher further refines.

• Screening: Vibrating screen classifies by size (such as 0-5mm, 5-10mm, 10-20mm, etc.).

• Auxiliary links: conveyor belt, dust removal system, wastewater treatment, etc.

3. What is the commonly used equipment?

• Crushing equipment: jaw crusher, cone crusher, impact crusher, hammer crusher

• Screening equipment: circular vibrating screen, linear vibrating screen, multi-layer screen.

• Auxiliary equipment: feeder, conveyor belt, dust collector, sand washer (if water washing is required).

4. How to choose crushing and screening equipment?

• Raw material characteristics: hardness (such as granite is harder), water content, and mud content.

• Production demand: small plant (50-100 tons/hour) or large plant (more than 500 tons/hour).

• Finished product specifications: required aggregate particle size range (such as coarse aggregate or machine-made sand).

• Environmental protection requirements: whether closed plant buildings, dust removal, and noise reduction measures are required.

5. How to lay out the production line?

• Terrain: Building on the mountain can reduce the energy consumption of material lifting.

• Process: The equipment is arranged in a step-by-step manner according to the order of crushing and screening, saving transportation costs.

• Space: Reserve maintenance passages and stockpiling areas.