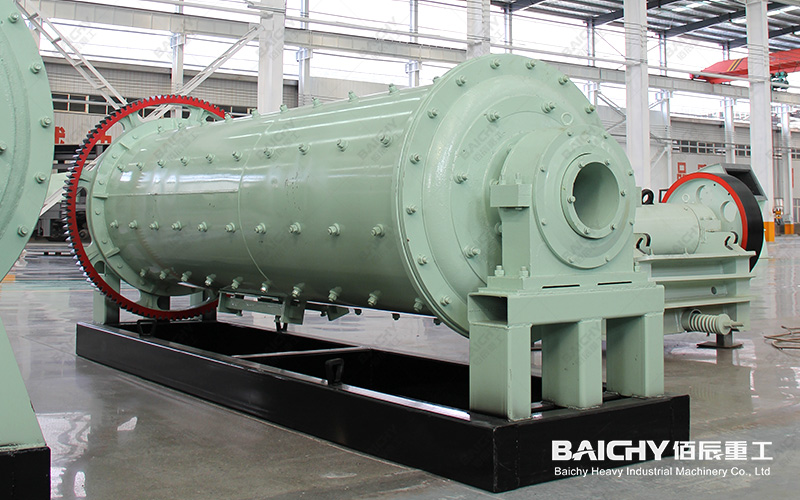

China Ball Mill Manufacturers, Suppliers and Factory

As a mineral processing equipment manufacturer with 20 years of industry experience, we deeply understand that in the complex process of gold ore beneficiation (gold washing plants), the stability and efficiency of each piece of equipment directly affect the final economic benefits. Among them, the wet ball mill plays an irreplaceable role as the "core grinder." This article will delve into the application of wet ball mills in gold washing plants, elucidate their key advantages, and share our professional insights.

| Key Words | China Ball Mill Manufacturers, Suppliers and Factory |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Wet Ball Mill Thematic Analysis: Why is it the Cornerstone of Gold Washing Plants?

In the gold ore beneficiation process, the raw ore must be crushed and ground to a sufficient particle size to allow for sufficient liberation of gold minerals, enabling effective recovery by subsequent gravity separation, flotation, or cyanidation processes. The wet ball mill is the key equipment responsible for this "liberation" task.

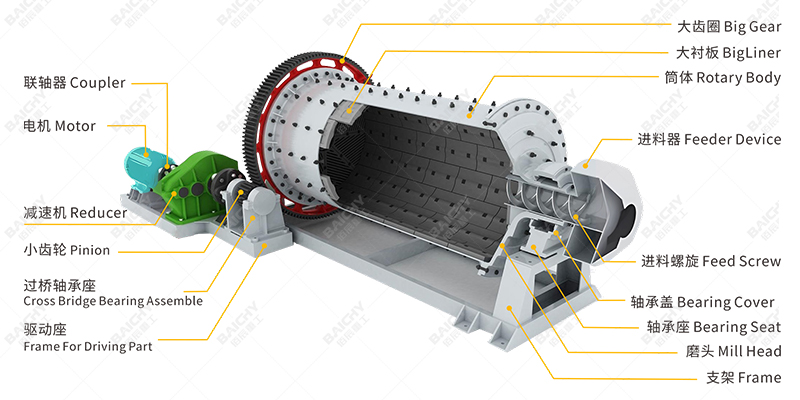

Ball mill structure diagram

Working Principle Overview

The wet ball mill uses a rotating cylinder to drive the internal grinding media (such as steel balls) to impact and grind the material. In wet grinding, the material is mixed with water to form a slurry, which is then fed into the ball mill. This not only effectively transports the material and prevents dust, but also provides preliminary classification and washing of the liberated fine-grained gold minerals, creating ideal conditions for downstream operations in the gold washing plant.

Core Advantages of Wet Ball Mills in Gold Washing Plants

Compared to traditional dry methods or other equipment, wet ball mills exhibit several significant advantages in gold washing plant applications.

Superior Liberation and Recovery Rates

Wet grinding more effectively exposes fine and micro-sized gold particles encased in gangue, significantly increasing the degree of gold liberation and directly improving the final recovery rate of the gold washing plant.

Operating Environment and Safety

Wet operations completely eliminate dust, improving the working environment of the gold washing plant and completely eliminating the risk of dust explosions, meeting the stringent requirements of modern mine safety production.

Process Adaptability and Continuity

The slurry morphology is perfectly adapted to subsequent gravity separation equipment such as jigs, centrifuges, and shaking tables, or it can directly enter the cyanide leaching tank, achieving smooth and continuous production throughout the gold washing plant and improving overall efficiency.

Ball mill customer site

Success Story: How Our Wet Ball Mill Helps Customers Increase Production

We provided a complete solution for a medium-sized gold mine washing plant in West Africa. This customer originally used a traditional process of direct cyanidation after crushing, with recovery rates consistently hovering around 65%. We designed and added a wet ball mill grinding section, grinding the ore to -200 mesh (75%).

• Result: The liberation degree of gold minerals was significantly improved, and the cyanide leaching rate increased to 92%. The customer recovered the equipment investment within one year. This wet ball mill, with its stable operation and low failure rate, became a key contributor to the improved quality and efficiency of the gold washing plant.

Equipment Selection and Maintenance Recommendations

How to Choose the Right Wet Ball Mill?

When selecting a wet ball mill, the following points should be considered:

1. Processing capacity and particle size: The model should be determined based on the daily processing capacity of the gold washing plant and the target grinding fineness.

2. Material and process: The materials of the cylinder liner and grinding balls (such as high manganese steel or chromium alloy steel) must be wear-resistant and corrosion-resistant. We use advanced heat treatment processes to extend their service life.

3. Power configuration: Matching a motor and reducer with appropriate power ensures sufficient power and energy saving.

Maintenance Points

Regularly checking the wear of the liner and steel balls, and the lubrication of the main bearing, and replacing or adding lubricant as needed, is crucial for ensuring the long-term stable operation of the wet ball mill and maintaining continuous production in the gold washing plant.

Frequently Asked Questions (FAQ)

1. Should a gold washing plant choose a wet ball mill or a dry ball mill?

Most gold washing plants recommend using wet ball mills. This is because they offer multiple advantages, including grinding, washing, dust prevention, and compatibility with subsequent processes, making them particularly suitable for use with cyanidation or gravity separation processes. Dry ball mills are only considered when water resources are extremely scarce or when there are special requirements for product moisture content.

2. Are wet ball mills energy-intensive? How to save energy?

Grinding is inherently an energy-intensive process. Our energy-saving solutions include: using large double-row self-aligning roller bearings to reduce transmission resistance, configuring high-efficiency energy-saving motors, optimizing the grinding media ratio and filling rate, and designing frequency conversion control according to customer needs, which can reduce energy consumption by 10-20%.

3. What is the service life of a wet ball mill?

Under normal maintenance and standardized operation, the core cylinder can last 15-20 years. The replacement cycle of wear parts such as liners and steel balls depends on the hardness of the ore; typically, liners are replaced every 6-18 months, and steel balls need to be replenished regularly. We provide comprehensive spare parts supply and technical support to ensure your gold washing plant operates smoothly.

Choosing a reliable wet ball mill lays a solid foundation for your gold washing plant. With 20 years of professional experience, we are willing to provide you with a full-process service from equipment selection and manufacturing to installation guidance, to jointly unlock the value of every gram of gold.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.