PE750x1060 jaw crusher is being shipped.

In the field of mining crushing, granite and basalt, with their extremely high hardness and wear resistance, are hailed as the ultimate test for crushing equipment. Facing these challenges, choosing a powerful, robust, and stable jaw crusher is crucial for the success of the production line.

As a manufacturer of mining crushing equipment with 20 years of deep industry experience, we understand our customers' pain points. Today, we will combine our experience to provide you with an in-depth analysis of the Baichy PE750X1060 jaw crusher's outstanding performance in crushing hard rocks such as granite and basalt.

I. Hard Rock Challenge: Why are Granite and Basalt So Difficult to Crush?

Before tackling the equipment, we first need to understand our competitors. Granite and basalt are both high-hardness ores, but their characteristics differ, posing different requirements for the crushing process.

| Rock Type | Main Characteristics | Core Crushing Challenges |

| Granite | High hardness (Mohs hardness 6-7), dense structure, high compressive strength, excellent wear resistance. | Difficult to bite, low crushing efficiency, severe wear on jaw plates. |

| Basalt | High hardness, high toughness, fine internal grains, and strong impact resistance. | Difficult to completely crush, easily produces flaky products, and has high energy consumption. |

These characteristics mean that crushing equipment must possess superior crushing force, excellent wear resistance, and intelligent adjustment capabilities, and the Baichy PE750X1060 was designed for this purpose.

II. Baichy PE750X1060 Jaw Crusher: A Powerful Heart Built for Hard Rock

The PE750X1060 is a classic medium-sized jaw crusher, widely used in the coarse crushing of various hard rocks. Its design fully integrates traditional reliability with modern innovation, making it a powerful tool for crushing hard rock.

1. Core Advantages: A Perfect Combination of Power and Durability

• Exceptional Crushing Force: Utilizing an optimized deep V-shaped crushing chamber design, not only is the feed opening size increased (750x1060mm), but the material also achieves better layered crushing within the chamber, resulting in a large single-pass crushing ratio, making it particularly suitable for the initial crushing of granite and basalt.

• Extreme Wear Resistance: The jaw plates of the moving and fixed jaws are made of high-manganese steel or even stronger alloy cast steel, undergoing a special heat treatment process. This allows for rapid hardening under immense impact and friction, increasing wear life by over 30% and effectively resisting the abrasive attack of hard rock.

• Stable and Reliable Operation: The overall frame adopts a welded heavy-duty steel structure, with even key components using cast steel, resulting in extremely high fatigue strength. Heavy-duty eccentric shafts and larger bearings ensure the equipment's operational stability under long-term high-intensity impact—the cornerstone of our equipment, valued most highly in our 20 years of experience.

2. Key Technologies and Parameter Analysis

Let's experience its strength through specific parameters:

| Item | Parameter/Description |

| Inlet Size | 750x1060 mm |

| Maximum Feed Particle Size | ≤630 mm |

| Discharge Port Adjustment Range | 80-200 mm |

| Processing Capacity | 110-320 t/h (depending on specific material characteristics and discharge port settings) |

| Spindle Speed | 250 r/min |

| Motor Power | 90-110 kW |

| Equipment Weight (approx.) | 28,000 kg |

Note: Processing capacity is based on medium-density granite, with a typical discharge port size of approximately 130 mm. When dealing with basalt, capacity may fluctuate slightly due to toughness factors, but stability remains excellent.

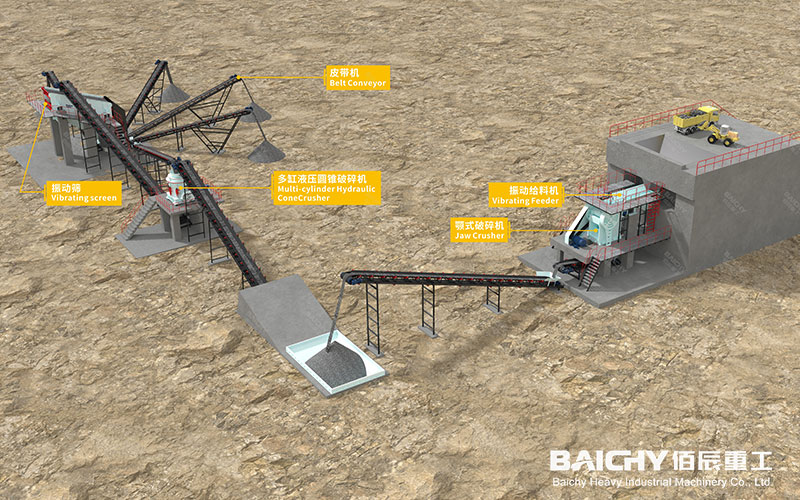

Aggregate crushing production line

III. How to Maximize the Performance of PE750X1060 in Hard Rock Production?

Equipment is the foundation; application is key. Based on our 20 years of experience in on-site service and process configuration, we offer the following recommendations to ensure you achieve the best return on investment:

1. Front-end feeding is crucial: Always configure a uniform and continuous feeding device (such as a vibrating feeder) to avoid starved or over-fed operation. For large granite pieces, ensure their particle size does not exceed the equipment's maximum feed limit to protect the jaw plates and prevent jamming.

2. Wear-resistant parts management strategy: Establish a regular jaw plate wear inspection system. When production capacity decreases significantly or product particle size coarsens, the jaw plates should be adjusted or reversed promptly. We recommend using original equipment manufacturer (OEM) wear-resistant parts to ensure optimal geometry and crushing efficiency.

3. Lubrication and maintenance: Strictly follow the manual for lubricating bearings and other critical components. Hard rock crushing generates a large amount of dust; ensuring the sealing and cleanliness of the lubrication system is paramount to ensuring long bearing life and preventing unexpected downtime.

4. Process Configuration Recommendations: For demanding finished sand and gravel aggregates, the process configuration of using PE750X1060 as coarse crusher, followed by a medium crusher (cone crusher for granite) or an impact crusher (for basalt, achieving better particle shape) has proven to be a classic, efficient, and economical solution.

| Application Scenarios | Recommended Process Routes (Examples) | Expected Results |

| Granite Aggregate Line | PE750X1060 Coarse Crushing Single-Cylinder Cone Crusher Medium Crushing Vibrating Screen | High output, low wear cost, controllable product particle shape, suitable for high-grade concrete aggregates. |

| Basalt Aggregate Line | PE750X1060 Coarse Crushing Heavy Impact Crusher Medium and Fine Crushing Screening | While ensuring output, it achieves better cubic particle shape, meeting the requirements of high-grade asphalt pavement aggregates. |

Crushing granite and basalt is a comprehensive test of equipment performance and manufacturer experience. The Baichy PE750X1060 jaw crusher, with its robust structure, superior wear resistance, and proven reliability, provides a solid foundation for this challenging task. As your partner with 20 years of practical experience, we not only offer this reliable equipment but also provide comprehensive value-added services throughout the entire lifecycle, from process design and installation to commissioning and operation optimization.

Choosing a reliable crusher means choosing lasting and stable productivity. Let the PE750X1060 become the core engine of your hard rock crushing production line, working together to mine a robust future.