Crawler Mobile Jaw Crusher

Mobile Ore and Aggregate Crushers (Track-Mounted Jaw Crushers) represent a core technological transformation in the modern mining and aggregate processing industry. As a professional manufacturer of mobile mining crushing equipment, we deeply understand the challenges faced by traditional fixed crushing production lines: high civil engineering costs, limited site adaptability, ever-increasing transportation costs, and environmental pressures. This track-mounted design was created to address these pain points.

The jaw crusher, as the oldest and most reliable crushing technology, combined with a track-mounted mobile platform, creates unique advantages. Its working principle is simple and robust – the periodic squeezing motion of the movable jaw against the fixed jaw achieves efficient crushing of various hard materials. This structure is particularly suitable for processing ores with compressive strength up to 350MPa and highly abrasive aggregate materials.

Equipment Overview: More Than Just a Mobile Crusher

Core Design Concept

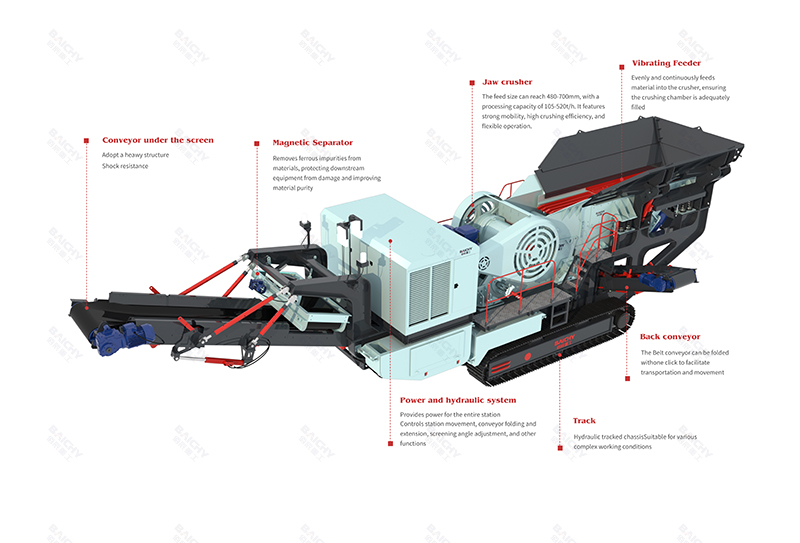

Our track-mounted jaw crushing station adopts a modular design concept, integrating feeding, crushing, conveying, and control systems into a compact mobile platform. Unlike traditional fixed production lines that require weeks or even months for installation and commissioning, our equipment can be put into production within hours of arriving on site.

Technical Parameter Range

Processing Capacity: 80-650 tons/hour, depending on the specific model and material characteristics

Feed Size: Up to 1,000×800×1,000mm

Discharge Particle Size: 60-300mm adjustable

Power Configuration: National III/National IV diesel engine or external power supply

Track System: Fully hydraulic drive, climbing ability up to 25°

Six Core Advantages Explained

Advantage One: Direct In-Pit Operation, Significantly Reducing Transportation Costs

Mobile crushers can operate directly at the mining face or quarry bench. This means that uncrushed raw materials that previously required transportation by large trucks now only need to be moved a short distance. According to our customer feedback, transportation costs can be reduced by 30%-60%.

Advantage Two: Excellent Terrain Adaptability

The track-mounted chassis provides unparalleled terrain traversal capabilities. Whether on soft soil, muddy construction sites, or slopes exceeding 15 degrees, our equipment maintains stable operation. This is an unparalleled advantage of the wheeled mobile crushing plant.

Advantage Three: Rapid Deployment and Flexible Relocation

“Arrive today, produce today” is not just a slogan. Our equipment can be set up and start production within 2-3 hours of arriving on site. When one work face is completed, the equipment can move to the next work face on its own, without disassembly and reinstallation.

Advantage Four: Environmentally Friendly Operation Mode

By reducing truck transportation, fuel consumption, dust emissions, and noise pollution are significantly reduced. At the same time, the equipment is equipped with advanced dust removal systems and noise control technology, meeting the strictest environmental standards.

Advantage Five: High Reliability and Easy Maintenance

The jaw crusher has a simple structure and robust components, resulting in a long average time between failures. Key components such as jaw plates and bearings use internationally renowned brands, and convenient maintenance access is provided.

Advantage Six: Intelligent Control System

Equipped with a PLC intelligent control system and remote monitoring function, operators can easily adjust parameters via a touchscreen, and managers can remotely monitor production status and equipment health via mobile phones or computers.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Successful Case Sharing

Case One: Hebei Iron Ore Project

The client faced the problem of excessively high relocation costs for traditional fixed production lines. The MC-160J crawler mobile jaw crusher we provided directly entered the mining pit to crush the iron ore to less than 250mm, and then transported it directly to the beneficiation plant via a conveyor belt. After project implementation:

Transportation costs reduced by 45%

Overall production efficiency increased by 30%

Investment payback period of only 8 months

Case Two: Sichuan Hydropower Station Aggregate Supply Project

Supplying sand and gravel aggregates for hydropower station construction in complex mountainous terrain. Traditional solutions required the construction of a large number of transportation roads. Our MC-120J equipment offers flexible mobility between multiple extraction points:

Reduced the need for 15 kilometers of dedicated road construction

Avoided large-scale forest land occupation

Completed supply tasks 2 months ahead of schedule

Equipment Selection Recommendations

Based on different production needs and material characteristics, we recommend the following configurations:

Small to medium-sized mines/quarries: C90 series, processing capacity 60-180 t/h, suitable for annual production of 500,000-1,000,000 tons

Medium-sized mines/large aggregate plants: C100 series, processing capacity 150-3000 t/h, suitable for annual production of 1,000,000-2,000,000 tons

Large mines/extra-large projects: C125 series, processing capacity 300-800 t/h, suitable for annual production of over 2,000,000 tons

Each piece of equipment can be customized according to the customer's specific material characteristics, product particle size, and site conditions to ensure optimal production efficiency and economic return.

Frequently Asked Questions (FAQ)

Question 1: What is the return on investment of a crawler-mounted jaw crusher compared to a traditional fixed production line?

Many of our customers recover their equipment investment within 12-18 months through savings in transportation and civil engineering costs. In the long term, due to significantly lower operating costs, the overall return on investment is usually 30%-50% higher than that of a fixed production line.

Question 2: How effective is the equipment in crushing high-hardness ores?

Jaw crushers are particularly suitable for processing high-hardness materials. Our equipment uses high-strength alloy steel jaw plates and a heavy-duty eccentric shaft design, capable of handling granite, iron ore, copper ore, etc., with compressive strengths up to 350 MPa. We also offer different jaw plate options to suit the crushing characteristics of different materials.

Question 3: Is the equipment maintenance complex?

On the contrary, our design philosophy is "easy to maintain." All daily maintenance points have convenient access passages and safety platforms. The lubrication system uses centralized automatic lubrication, and the key component monitoring system can provide early warnings of potential failures. We provide comprehensive operational training and detailed maintenance manuals.

As a professional manufacturer of mobile mining crushing equipment, we have witnessed how this technology is transforming the production model of the entire industry. Track-mounted mobile jaw crushers represent more than just mobile equipment; they embody a revolution in production philosophy—representing flexibility, efficiency, and sustainability.

If you are considering how to optimize your ore or aggregate production process, reduce operating costs, and enhance competitiveness, then gaining a deeper understanding of mobile crushing solutions will be one of the wisest decisions you can make. Please contact our technical team to receive a customized solution tailored to your specific needs.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!