In the fiercely competitive mining industry, the continuity and stability of equipment operation directly impact a company's profitability. As the primary crushing vanguard on the production line, the performance of the PE600x900 jaw crusher is crucial. The core factors determining its performance, lifespan, and overall efficiency often lie not in the main unit itself, but in the wear-resistant components that directly combat hard materials.

PE Jaw Crusher PDF,Download ↓↓↓

As a marketing expert with years of experience in the mining equipment field, I understand your pain points: frequent downtime for replacements, high parts consumption, unstable crushing efficiency… these problems are silently eroding your profits. Today, we will delve into the key wear-resistant components of the PE600x900 jaw crusher and tell you how the right choice can become your secret weapon for cost reduction and efficiency improvement.

I. Analysis of Key Wear-Resistant Components of the PE600x900 Jaw Crusher

We often call jaw plates, side guards, etc., wear parts, but this term underestimates their strategic value. A more accurate description is key wear-resistant components or core consumable parts. Their condition directly determines the crusher's output particle size, capacity, and the stability of the entire production system.

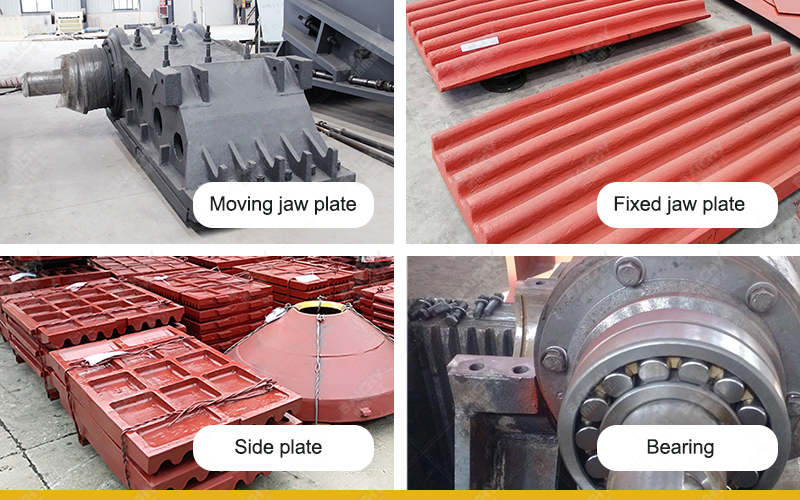

1. Moving Jaw Plate and Fixed Jaw Plate: These are the core components of the crushing chamber, directly responsible for squeezing and crushing materials. Their material, tooth shape design, and heat treatment process are key to quality.

◦ Material Selection: The mainstream high-end choice is ultra-high manganese steel (such as Mn18Cr2). Under strong impact and squeezing, the surface of this material hardens rapidly, forming a hard, wear-resistant layer, while the inner layer retains excellent toughness, resulting in crack resistance far exceeding that of ordinary manganese steel.

◦ Tooth Shape Optimization: Depending on the hardness and abrasiveness of the material being crushed, different tooth shapes (such as wavy, triangular, etc.) can be selected to optimize crushing efficiency and product particle shape.

2. Side Guard Plates: Located on both sides of the crushing chamber, they primarily prevent material from wearing down the sides of the moving jaw assembly. Although not directly involved in crushing, they protect the more expensive core assembly. High-quality side guard plates should possess a balance of high hardness and good toughness.

3. Toggle Plate (Thrust Plate): It serves as both a force transmission component and a safety device for the equipment. When uncrushable objects (such as iron blocks) enter the cavity, the toggle plate will break first, protecting other core components from damage. Its strength and reliability are crucial.

II. Beyond Price: The Life-Cycle Value of High-Quality Wear-Resistant Components

Many customers focus on the unit price when purchasing spare parts. However, as an expert, I must emphasize that cost per ton is the gold standard for measuring the value of spare parts.

• The Trap of Low-Priced Spare Parts: Spare parts made of ordinary steel and with poor manufacturing processes may have an initial purchase cost 20%-30% lower, but their wear life may only be one-third or even less of that of high-quality spare parts. This means more frequent downtime for replacements, leading to lost output, increased labor costs, and ultimately, a significant increase in the cost per ton of crushing.

• The Long-Term Value of High-Quality Spare Parts:

◦ Longer Service Life: The service life of ultra-high manganese steel jaw plates can be more than 50% longer than that of ordinary materials.

◦ Enhanced operational stability: Uniform wear translates to more stable output particle size, ensuring efficient operation of downstream equipment.

◦ Lower overall downtime costs: Reduced replacement frequency directly increases equipment uptime and output value.

III. How to Choose a Reliable Partner for Your PE600x900?

1. Material Certification: Request material reports from suppliers to confirm the promised high-end alloy (e.g., Mn18Cr2).

2. Manufacturing Process: Understand whether their heat treatment processes (e.g., water quenching) are advanced and controllable; this is crucial for maximizing material potential.

3. Technical Support: Excellent suppliers not only provide products but also recommend the most suitable tooth shape and material based on your crushing materials (granite, basalt, river pebbles, etc.) and provide installation guidance.

4. Success Stories: Examine whether the supplier has successful application experience in large-scale mining projects; this is strong evidence of the reliability of their product quality.

In the protracted battle of mining operations, wear-resistant parts for the PE600x900 jaw crusher are far more than just a procurement item; they are a strategic resource impacting the overall operation. Choosing us means not only receiving a set of wear-resistant parts that meet or even exceed original equipment manufacturer (OEM) standards, but also a long-term partner dedicated to enhancing your overall efficiency. Let us use superior quality and professional knowledge to build a solid defense for your crushing production line.