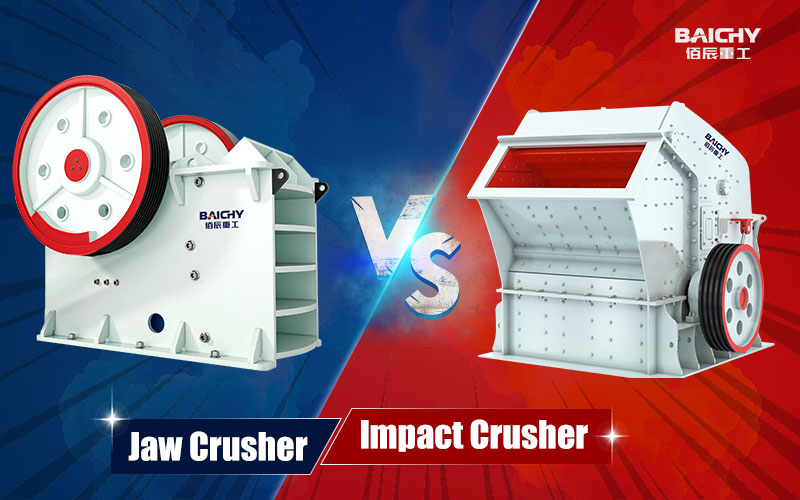

Which Is Better: Jaw Crusher Or Impact Crusher?

In the mining crushing field, the question of which is better a jaw crusher or an impact crusher is a frequently asked but often oversimplified question. As a mining crushing equipment manufacturer with 20 years of experience, we understand that the real question behind this is: Which crusher is more suitable for my specific materials, production requirements, and investment budget? The two are not simply interchangeable; they are core pieces of equipment that perform different functions and have different advantages in the crushing process. The key to choosing the right one lies in understanding the differences in their principles and applicable scenarios.

PE Jaw Crusher

PF Impact Crusher

Equipment Overview and Working Principles

- Jaw Crusher: Uses the squeezing and bending action of two jaw plates (moving jaw and stationary jaw) to crush materials. Its working principle is similar to an animal's jaws chewing, belonging to the layered crushing principle. It is usually the preferred choice for primary crushing in crushing production lines, used for processing large, high-hardness raw ore.

- Impact Crusher: Primarily uses a high-speed rotating rotor to drive hammer plates to impact the material, causing the material to collide with the impact plate or with each other for crushing. It belongs to the stone-on-metal or stone-on-stone impact crushing principle. It is usually used in the secondary crushing or sand making and shaping stage, processing materials of medium hardness and below.

Core Advantages Comparison: Tailored Solutions for Different Needs

| Feature Dimension | Jaw Crusher | Impact Crusher |

| Crushing Ratio | Relatively small (usually 4-6), coarser output | Large (up to 40 or more), good output particle shape |

| Product Particle Shape | Slightly higher content of needle-shaped and flaky particles, generally average particle size uniformity | Excellent, cubic shape, reasonable gradation, suitable for high-standard aggregates and manufactured sand |

| Applicable Material Hardness | High, excels at processing highly abrasive materials such as granite, basalt, and river pebbles | Medium to low, more suitable for limestone, dolomite, construction waste, etc. |

| Energy Consumption and Wear | Relatively low unit power consumption, long jaw plate wear cycle, simple maintenance | Unit power consumption may be higher, hammer plates and impact plates wear faster, but replacement is convenient |

| Investment and Operating Costs | Moderate equipment investment, relatively low operating and maintenance costs | Equipment investment may be slightly higher, but the finished product value is high, and the fine crushing and sand making efficiency is outstanding |

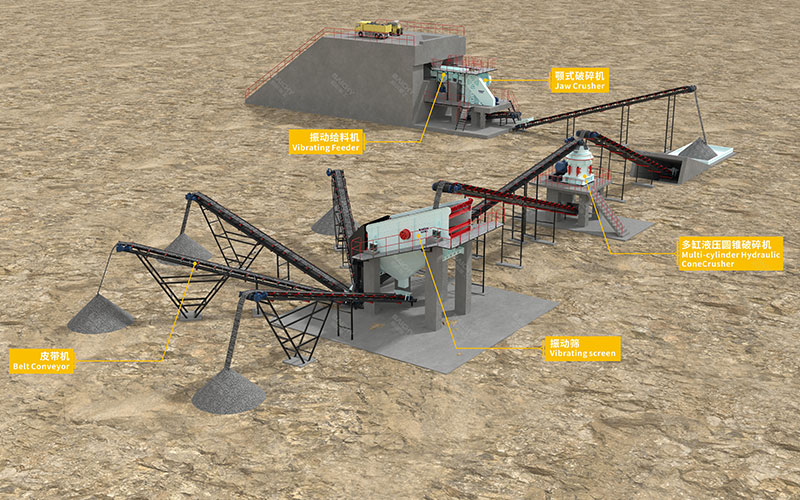

Impact crushing production line

Practical Application Case Analysis

In many projects we have served, a combination of both types of equipment is often the optimal solution:

Case Study 1: Large-scale Granite Crushing Production Line

- Configuration: Jaw crusher (primary crushing) + cone crusher (secondary crushing) + impact crusher (shaping and sand making).

- Analysis: Utilizing the high-strength coarse crushing capability of the jaw crusher to process the raw ore, and then using the impact crusher to perform final shaping on the material after secondary crushing by the cone crusher, resulting in high-quality manufactured sand and 12/13 mm aggregate. This is a classic and efficient solution for high-hardness material production lines.

Case Study 2: Construction Waste Resource Utilization Line

- Configuration: Feeder + impact crusher (with iron removal and pre-screening).

- Analysis: Here, the impact crusher becomes the core component. Its impact crushing principle effectively processes complex construction waste, and its excellent particle shape control capabilities allow it to directly produce recycled aggregates that meet standards, achieving multi-functionality in one machine.

Manufacturer's Purchase Recommendations

1. Consider material hardness and particle size: If the material is extremely hard and the blocks are large, a jaw crusher is the first choice for primary crushing. If the material is of medium to low hardness and requires high-quality finished product particle shape, an impact crusher has significant advantages.

2. Consider product requirements: For producing mainly coarse aggregates, a jaw crusher + cone crusher solution is recommended. If the goal is to produce high-quality crushed stone and manufactured sand, an impact crusher is indispensable.

3. Consider production scale and budget: For stable, low-consumption primary crushing, choose a jaw crusher. For flexible, efficient fine crushing and shaping, and if you can accept relatively higher wear part costs, choose an impact crusher.

4. Best practice: In a complete crushing and screening system, jaw crushers and impact crushers are often a golden combination, working together to achieve optimal crushing results and economic benefits.

Frequently Asked Questions (FAQ)

Q1: Can the entire crushing process be completed using only an impact crusher?

A: For materials with medium hardness or less and small input particle size (such as limestone), a single-stage impact crusher can be attempted. However, for large, high-hardness ores, direct use will accelerate wear, reduce efficiency, and significantly increase wear part costs, so it is not recommended.

Q2: Can a jaw crusher produce fine materials?

A: The outlet can be adjusted, but its capacity is limited, the particle shape is poor, and the output will be significantly reduced. Its main function is coarse crushing; fine crushing is not its strength.

Q3: Which equipment is easier to maintain?

A: Jaw crushers are generally considered to have a simpler and more reliable structure, with fewer maintenance points and a longer jaw plate replacement cycle. Impact crushers require more frequent replacement of wear parts such as blow bars, but modern designs have made the replacement process very convenient.

Q4: As a manufacturer with 20 years of experience, how do you guarantee equipment quality?

A: We possess full control over the entire production chain, from casting and heat treatment to machining. Our core components (such as jaw plates, impact plates, and rotors) utilize custom-designed alloy materials and can be specifically tailored to the customer's materials, ensuring both durability and high efficiency.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.