The Differences Between Impact Crusher And Hammer Crusher

Impact crushers and hammer crushers are two common and easily confused types of medium and fine crushing equipment on the market. This article will provide a thorough analysis of the core differences between the two from multiple dimensions, including principles, structure, applicable materials, and advantages, to help you make an informed decision.

In-depth Analysis: Fundamental Differences in Working Principles

Although both utilize impact energy to crush materials, their implementation methods and core structures are distinctly different, which determines their different performance curves and application scenarios.

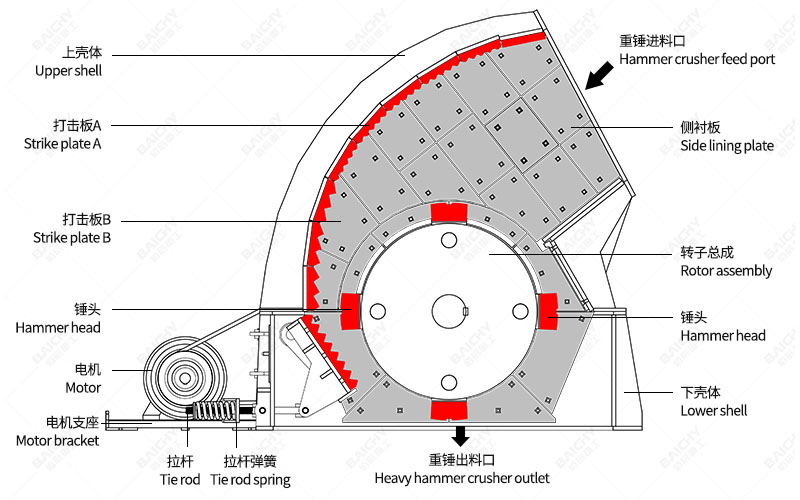

Structural diagram of a heavy-duty hammer crusher

Hammer Crusher: Employs the principle of impact and grinding. Its core component is a set of movable hammers mounted on a rotor. After the material enters the machine, it is crushed by the impact of the high-speed rotating hammers and simultaneously subjected to secondary crushing by impacting against the liner plates. Materials smaller than the sieve plate gap are then discharged.

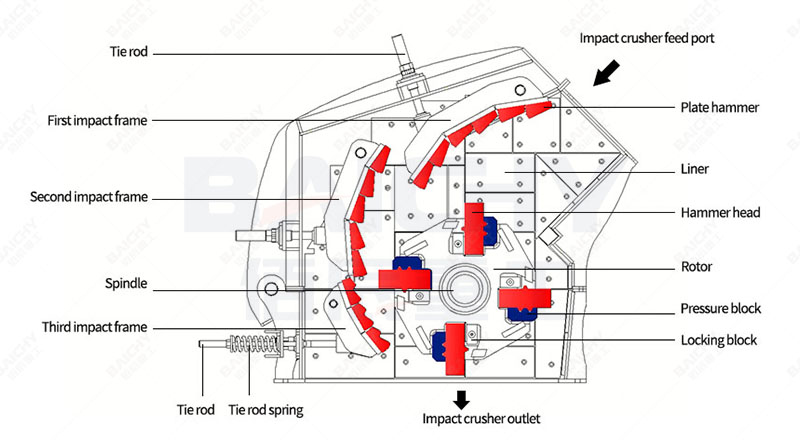

Structural diagram of the impact crusher

Impact Crusher: Employs the pure impact principle of stone-on-stone or stone-on-metal. The material is accelerated and thrown out by a high-speed rotating impeller, and then crushed by high-speed impact and friction against the naturally formed material lining or impact liner plates around the crushing chamber, achieving self-crushing of the material.

Overview of Key Differences

| Feature | Hammer Crusher | Impact Crusher |

| Crushing Principle | Hammer impact + material collision with liner | High-speed impact and friction between materials (self-crushing) |

| Wear of Wear Parts | Very high (hammers and liners directly contact the material) | Lower (wear is mainly concentrated in the impeller flow channel, material lining protects the machine body) |

| Finished Product Particle Shape | More needle-shaped and flaky particles, high powder content | Excellent particle shape, mostly cubic, reasonable gradation |

| Feed Particle Size | Larger (can handle large materials with side lengths of 400-800mm) | Relatively smaller (usually side lengths of 50-60mm or less are preferred) |

| Moisture Content Requirements | Relatively strict, prone to clogging the grate bars | Stronger adaptability, can handle materials with slightly higher moisture content |

| Energy Consumption | Relatively low | Relatively high |

| Main Advantages | Large crushing ratio, single-stage crushing, simple structure | Good particle shape, controllable wear costs, suitable for high-hardness materials |

Advantages and Application Scenarios of Each

Heavy Hammer Crusher

Advantages of Hammer Crushers

1. Single-stage crushing: A single machine can achieve a large crushing ratio, simplifying the process flow.

2. Economical price: Initial investment costs are usually lower than impact crushers.

3. Simple operation and maintenance: Straightforward structure, easy to understand and maintain.

Classic Case: A limestone quarry with raw material particle size ≤800mm, requiring a product of 0-25mm building aggregate. A heavy-duty hammer crusher is used for single-stage crushing, resulting in a simple production line configuration and quick return on investment.

PF Impact Crusher

Advantages of Impact Crushers

1. Top-quality finished product: The produced sand and gravel aggregate fully meets the requirements of high-standard building materials, making it the preferred equipment for manufactured sand.

2. Long wear part life: The unique material self-lining principle significantly reduces operating wear costs. 3. Flexible Adjustment: The discharge particle size can be easily controlled by adjusting the rotor speed and the gap between the impact plates.

Classic Case: A large-scale high-speed rail project's aggregate base uses high-hardness granite as raw material, requiring the production of high-quality aggregates and manufactured sand with excellent gradation and particle shape. The process uses a jaw crusher + cone crusher + impact crusher system, where the impact crusher is the key shaping equipment, ensuring the high quality and high value of the finished product.

Equipment Selection Recommendations

Prioritize Hammer Crushers when: processing medium-to-low hardness materials (such as limestone, coal gangue), aiming for single-stage crushing to reduce investment, having low requirements for finished product particle shape, and having low raw material moisture content.

Prioritize Impact Crushers when: processing medium-to-high hardness materials (such as granite, river pebbles), having strict requirements for finished product particle shape and gradation (such as producing manufactured sand), focusing on the overall wear cost of long-term operation, and pursuing high added value for the product.

Related Equipment Recommendations

An efficient crushing production line often requires multiple machines working together. In addition to the core secondary crushing equipment (hammer crusher or impact crusher), we can also provide:

Primary Crushing: PE series deep-cavity jaw crushers, used for coarse crushing of large materials.

Medium and Fine Crushing: HPT multi-cylinder hydraulic cone crushers, used for energy-efficient fine crushing of ultra-high hardness materials.

Feeding and Screening: ZG series vibrating feeders and YKN series circular vibrating screens, forming a complete closed loop.

FAQ Frequently Asked Questions

Q1: Which equipment is more suitable for producing manufactured sand?

A1: From the perspective of finished product particle shape, gradation, and fines content control, impact crushers (vertical shaft impact crushers) are the preferred choice for professional sand making. Although hammer crushers can also produce sand, they have a high content of flaky particles, and the quality usually cannot meet high-standard requirements.

Q2: Which equipment has lower operating costs?

A2: Initially, hammer crushers have lower costs; however, in the long run, impact crushers have slower wear on wear parts, and the high-quality aggregates they produce command a higher price. Therefore, the overall operating costs may be more advantageous, especially for hard materials.

Q3: Can they be used interchangeably?

A3: They can be interchangeable in some applications involving medium-soft materials and where particle shape is not critical. However, in core application areas, their focuses differ, and they are not completely interchangeable. A comprehensive assessment based on material characteristics, product requirements, and investment budget is necessary.

Q4: What are the advantages of your equipment in terms of wear-resistant materials?

A4: Based on 20 years of experience, we use persified alloy formulas and heat treatment processes for key wear parts (such as hammer heads, impact blocks, and liners), and can customize them according to customer materials. This maximizes the service life of wear parts and reduces downtime.

In summary, the core difference between hammer crushers and impact crushers lies in their crushing principles and the resulting particle shape. There is no absolute better option, only the more suitable one. As an experienced mining equipment manufacturer, we not only provide high-quality equipment but also offer professional selection advice and comprehensive solutions. Welcome to contact us and share your material information and production needs; we will customize the optimal solution for you.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.