Crawler Type Crushing and Screening Plant Selection

In mining, construction demolition, and road construction, crawler-mounted crushing and screening equipment has become synonymous with efficient and flexible production. However, with the wide variety of brands and models on the market, many users are confused about how to choose the equipment that best suits their project needs. As a mobile crushing equipment manufacturer with 20 years of experience, we understand that a properly selected piece of equipment can not only maximize production efficiency but also significantly reduce long-term operating costs. This article will systematically outline the key considerations for selecting crawler-mounted crushing and screening equipment, starting from core principles.

| Key Words | Crawler Type Crushing and Screening Plant Selection |

|---|---|

| Product Model | Crawler Impact Crusher |

| Feed Size | 0-800mm |

| Motor Power | 100-500kw |

| Capacity | 100-500 t/h |

| Core Equipment | CI Impact Crusher |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Defining Core Needs: The First Step in Equipment Selection

Before comparing specific models, you must clearly define your project requirements. This is the foundation of all mobile crushing equipment selection.

1. Material Characteristics:

• Hardness and Abrasiveness: The Mohs hardness and SiO2 content of the material directly determine whether a jaw crusher, impact crusher, or cone crusher should be used. Highly abrasive materials pose a significant challenge to the wear-resistant materials and structure of the equipment.

• Particle Size and Grading: The maximum feed size of the raw material and the required specifications and grading of the finished product are crucial for determining the type of crushing main unit and the number of screening layers.

2. Production Capacity Requirements: Based on the project cycle and production targets, determine the required hourly processing capacity of the equipment. Be sure to include a margin of approximately 10%-15% to accommodate peak demand.

3. Working Conditions and Site: Does the equipment need to be frequently moved? Is the site narrow and rugged? This determines the importance of the crawler-mounted crushing and screening equipment's chassis passability, mobility, and rapid setup capabilities.

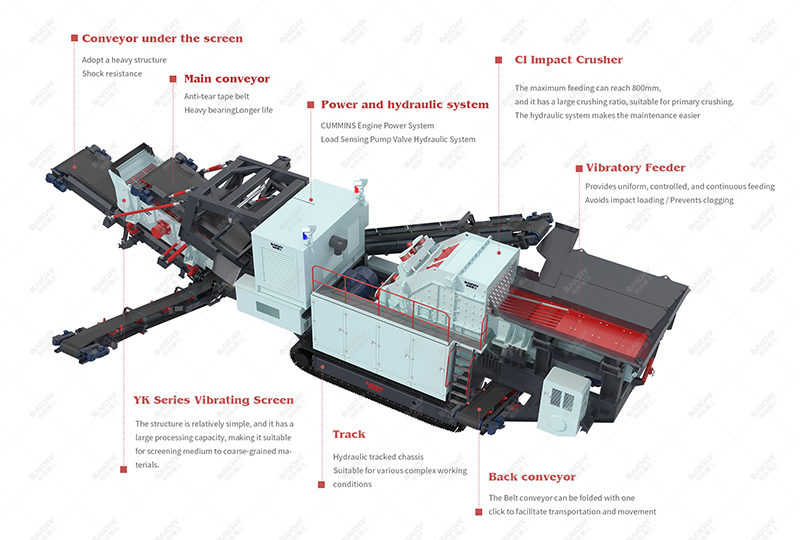

Track-mounted impact crusher structural diagram

II. In-Depth Analysis of Key Components: The Core of Quality from a Manufacturer's Perspective

An excellent crawler-mounted mobile crushing plant is the result of the coordinated work of its various core components.

• Crushing Main Unit: This is the heart of the equipment. In addition to the type selection, attention should be paid to whether its design is advanced (such as a deeper crushing chamber, a better bite angle), whether the hydraulic adjustment of the discharge opening is convenient, and whether the iron protection is reliable. With 20 years of experience, we have accumulated numerous patents in main unit optimization, ensuring high output and low flaky particle content.

• Crawler Chassis: As the legs, it needs to provide excellent stability and mobility. Key considerations include chassis strength, the reliability of the hydraulic drive system, ground pressure, and climbing ability. Professional mobile crushing equipment manufacturers will implement reinforced designs for heavy-duty crushing conditions.

• Screening System: Efficient screening is crucial for obtaining qualified finished products and improving overall efficiency. Attention should be paid to the strength of the screen box structure, vibrator performance, screen mesh material, and the ease of quick replacement. Multi-layer screening designs can produce multiple material specifications in a single pass.

• Power System: There are usually two types: diesel-electric and all-diesel. Diesel-electric (with built-in generator) is more economical and quieter; all-diesel drive is more adaptable in situations without external power. Key factors are the engine brand, power reserve, and fuel efficiency.

• Control System: Modern advanced crawler-type crushing and screening equipment comes standard with a PLC intelligent control system. It should have touchscreen operation, fault diagnosis, equipment operating parameter monitoring, and even remote networking capabilities. This is crucial for reducing operating difficulty, ensuring safety, and enabling preventative maintenance.

III. Considerations Beyond Parameters: Intangible Value

When choosing equipment, don't just focus on the parameter sheet. As an experienced manufacturer, we recommend you pay more attention to the following:

• Installation and Commissioning Services: Professional guidance ensures the equipment quickly reaches its optimal state.

• Spare Parts Supply and Interchangeability: A stable spare parts supply chain and high component interchangeability minimize downtime.

• Operation and Maintenance Training: Whether the manufacturer provides comprehensive training directly impacts the equipment's performance and lifespan.

• Manufacturer's History and Reputation: 20 years of experience means having gone through multiple product iterations and market testing, resulting in more mature equipment reliability and problem-solving capabilities.

Let professional experience safeguard your investment

Crawler-type crushing and screening equipment is a significant investment. Successful selection is a comprehensive process of accurately matching project needs, deeply understanding the equipment's core features, and choosing a reliable partner. We recommend that before making a decision, you provide material samples for testing and witness the equipment's performance firsthand. As a mobile crushing equipment manufacturer with 20 years of experience in the industry, we can provide not only various crawler-type crushing and screening equipment from single units to complete production lines, but also offer targeted selection advice and full lifecycle support to help you build a solid foundation for your business.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.