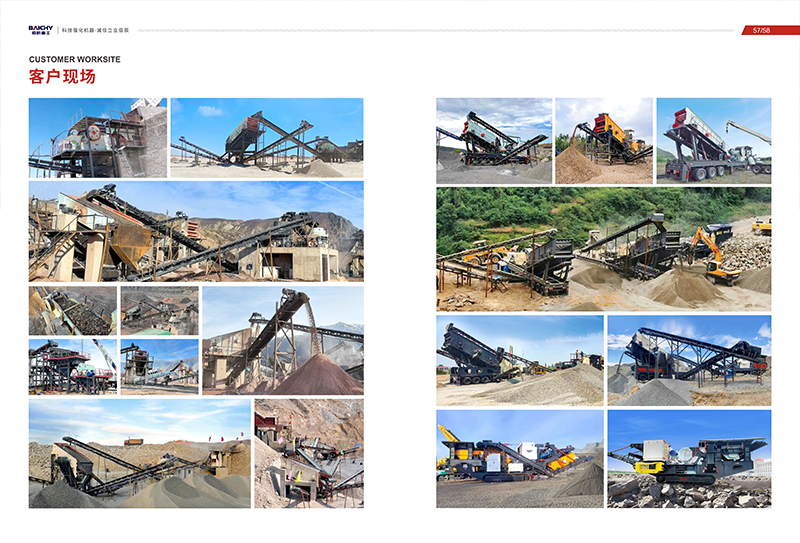

Baichy Heavy Industry's global customer crushing site

In numerous fields such as mining, aggregate processing, and construction waste recycling, crushing equipment is the heart of the entire production line. The correct selection of crushing equipment directly determines the efficiency, finished product quality, and operating costs of the entire production line.

As a seasoned professional and marketing expert in the mining equipment industry, I am well aware of the confusion customers face when choosing equipment: Faced with a dazzling array of crusher types on the market, such as cone crushers, jaw crushers, impact crushers, and gyratory crushers, how should one choose?

Today, we will simplify the complex by deeply analyzing the working principles, performance characteristics, and applicable scenarios of these four mainstream crushers, providing you with an authoritative and practical purchasing guide.

Type of jaw crusher

I. Jaw Crusher Conquering with Force

The jaw crusher is considered a pioneer in mining crushing, playing a primary crushing role in almost all sand and gravel production lines.

• Working Principle: Simulating the movement of an animal's jaws, large pieces of material are crushed to medium particle size through periodic compression and separation between the moving and stationary jaws.

• Core Advantages: Simple and robust structure, reliable operation, convenient maintenance, and a large feed opening, easily handling giant rocks with a particle size of up to 1500mm. Its extremely high reliability and adaptability to harsh working conditions make it the ideal choice for primary crushing.

• Applicable Scenarios: Primarily used for primary crushing of hard materials such as granite, basalt, and river pebbles. It is the core equipment in the primary crushing stage of both stationary and mobile crushing plants.

• Marketing Perspective: For customers, the jaw crusher is the cornerstone of their investment. Its high stability and low failure rate mean continuous production, directly ensuring the smooth operation of subsequent stages. In marketing, we should emphasize its core values of robust durability and high cost-effectiveness.

Type of Cone Crusher

II. Cone Crusher Winning with Stability

After the initial slimming of the material by the jaw crusher, more refined processing is required. The cone crusher is the technical backbone of the medium and fine crushing stages.

• Working Principle: Utilizing the principle of layered crushing, the moving cone performs eccentric gyratory motion within the fixed cone, continuously compressing, shearing, and grinding the material.

• Core Advantages: High crushing efficiency, relatively low energy consumption, excellent finished product particle shape (mostly cubic), long wear part life, and stable operation. The fully automatic hydraulic control system allows for easy adjustment of the discharge port size, achieving precise material control.

• Applicable Scenarios: Suitable for secondary and tertiary crushing of medium-to-high hardness materials, it is a key piece of equipment for producing high-quality manufactured sand and premium aggregates.

• Marketing Perspective: The value of a cone crusher lies in its quality and efficiency. It can produce high-value-added, high-quality aggregates to meet the demands of the high-end construction market. In marketing, we should focus on its ability to increase product selling price and reduce overall cost per ton, attracting customers seeking long-term returns and product upgrades.

Type of Sand Making Machine

III. Impact Crusher (Sand Making Machine)

If you are looking for excellent particle shape and efficient sand making capabilities, an impact crusher (often called a sand making machine) is your ideal choice.

• Working Principle: Utilizing the stone-on-stone or stone-on-iron principle, a high-speed rotating impeller accelerates the material, causing it to collide with each other or with the surrounding guard plates, thus crushing it.

• Core Advantages: Excellent particle shape shaping capability; finished particles are cubic with a reasonable gradation, making it particularly suitable as high-standard concrete sand; it combines crushing and shaping functions, resulting in high sand production efficiency.

• Applicable Scenarios: It is the core equipment for manufactured sand production and is also commonly used in tertiary crushing where stringent requirements for aggregate particle shape are placed. It is especially suitable for shaping and sand production of materials with medium hardness or lower (such as limestone).

• Marketing Perspective: Impact crushers are a powerful tool for product differentiation. In fierce market competition, superior particle shape means higher selling prices and stronger market competitiveness. Marketing focus should be placed on enhancing product competitiveness and meeting high-standard requirements, directly addressing customers' pain points for increasing profits.

Type of Gyratory Crusher

IV. A Capacity Giant: Gyratory Crusher Reigning Supreme in Quantity

For large and even super-large mining projects, the gyratory crusher is the ultimate solution for handling massive capacity demands.

• Working Principle: Similar to a cone crusher, but with a much larger structure, a huge feed opening, and a rotating cone within the frame.

• Core Advantages: Extremely high processing capacity (up to tens of thousands of tons per hour or more), continuous feeding and discharging, stable operation, and low energy consumption per unit product. It can directly process raw ore transported from the mine, eliminating the need for primary blasting.

• Applicable Scenarios: Specifically designed for primary crushing in large open-pit mines and large aggregate production bases, it is truly designed for massive production.

• Marketing Perspective: The gyratory crusher targets strategic clients. While the investment is substantial, the resulting economies of scale and operational cost advantages are revolutionary. Marketing communication should focus on total life cycle cost, return on investment, and advantages of large-scale production, discussing long-term strategic cooperation with clients, rather than simply buying and selling equipment. There is no single best crusher, only the most suitable combination. An efficient and economical production line is often a scientifically balanced combination of these four kings:

• Classic combination: Gyratory/jaw crusher (primary crushing) + Cone crusher (medium and fine crushing) + Impact crusher (shaping and sand making)

• Flexible combination: Jaw crusher (primary crushing) + Impact crusher/cone crusher (secondary crushing)

As a seasoned equipment supplier, our value lies not only in providing high-quality inpidual machines, but also in tailoring the optimal overall crushing and screening solution to your specific material characteristics, capacity requirements, finished product specifications, and investment budget. Choosing us means choosing a trustworthy mining crushing expert.