In today's mining industry, which prioritizes efficiency, low carbon emissions, and flexible production, mobile crushing equipment has become crucial for enhancing operational competitiveness. As a manufacturer of mobile crushing equipment for mines, we understand the importance of choosing the right "crushing plant on tracks" for project success. This article will delve into the core value, advantages, and applications of mobile crushing plants in mining, helping you make informed decisions.

Mobile Crushing Plants: A Revolutionary Solution for Modern Mining

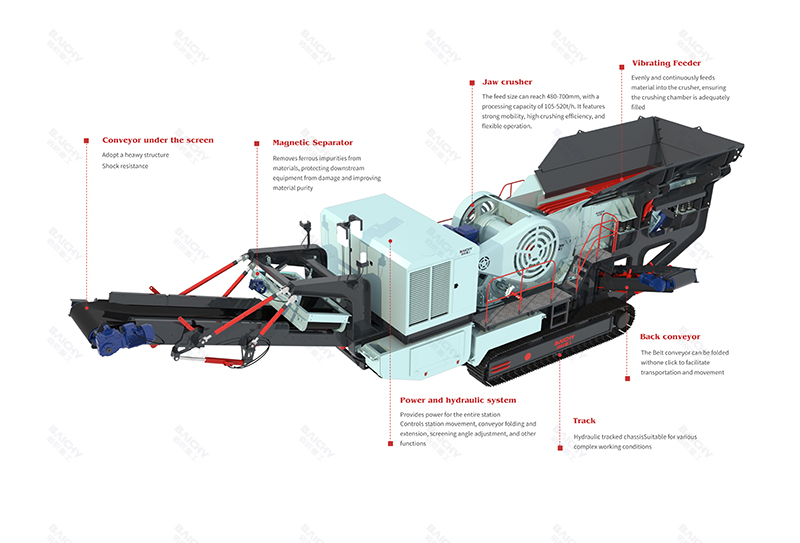

Traditional fixed crushing production lines require complex infrastructure, high installation costs, and significant expenses for relocation as the mining area expands. Mobile crushing equipment completely transforms this model, integrating feeding, crushing, and screening systems onto a single or a set of mobile chassis, enabling efficient operation with the ability to crush materials wherever they are located.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Core Advantages Analysis: Why Have Mobile Crushing Plants Become Mainstream?

Unparalleled Flexibility: The equipment can be driven directly to the mining face, even deep into the pit, significantly shortening the distance for material transportation and reducing truck transportation costs and energy consumption. It can be quickly moved between different mining areas or projects, enabling multi-purpose use of a single machine.

Significant Cost Reduction and Efficiency Improvement: It eliminates the need for concrete foundations, steel structures, and long conveyor belts required for fixed production lines, resulting in a lower investment threshold. Production starts quickly; after arrival on-site and connection to power, it can be put into production rapidly, accelerating return on investment.

Excellent Environmental Protection and Safety: By processing materials close to the source, it significantly reduces the number of on-site transport vehicles and dust sources, lowering noise and dust pollution. The integrated safety protection and intelligent monitoring systems also provide a safer environment for operators.

Intelligent Operational Management: Modern high-end mobile crushing equipment is generally equipped with remote monitoring, fault diagnosis, and automated feeding systems. Operators can easily monitor production status and optimize crushing parameters from the control room, achieving stable and high output.

Success Stories: The Outstanding Performance of Mobile Crushing Plants in Various Mines

Case Study 1: Large Open-Pit Metal Mine

A large iron mine faced the challenge of increasingly deeper pits and rising transportation costs. We configured an ultra-high-capacity crawler-mounted jaw crusher mobile plant for primary crushing, combined with a crawler-mounted cone crusher mobile plant for secondary and tertiary crushing. The two units formed a mobile crushing line underground, directly crushing the ore to the required particle size, which was then transported out via an in-pit belt conveyor, reducing overall transportation energy consumption by approximately 35%.

Case Study Two: Construction Aggregate Limestone Mine

A limestone mine located in complex mountainous terrain needed to supply multiple projects with different particle size requirements simultaneously. We recommended a flexible combination of "crawler jaw crusher + crawler impact crusher + mobile screening plant". This combination allows for quick adjustment of screen configurations and production locations based on different project order requirements, producing various specifications of high-quality aggregates to meet diverse market demands, demonstrating exceptional site adaptability.

How to Choose the Right Mobile Crushing Equipment for Your Mine?

Select the main machine based on material characteristics: For high-hardness ores (such as granite and iron ore), crawler-mounted jaw crusher mobile plants and crawler-mounted cone crusher mobile plants should be prioritized; for medium-to-low hardness rocks (such as limestone and construction waste), crawler-mounted impact crusher mobile plants are a more economical and efficient choice.

Consider production scale and process configuration: Single-unit independent operation, or "multi-unit combined operation" (such as jaw crusher + cone crusher dual units). We provide comprehensive solutions ranging from 200 tons/hour to over 1000 tons/hour.

Focus on intelligence and after-sales service: Choosing a manufacturer equipped with a reliable intelligent control system, providing comprehensive spare parts support and localized technical services is crucial to ensuring the long-term stable operation of the equipment.

Frequently Asked Questions (FAQ)

Q1: Can mobile crushing plants meet the needs of large mines?

A1: Absolutely. Modern large-scale mobile crushing equipment, especially crawler-mounted cone crushers and jaw crushers, have a single-unit processing capacity of up to 600-1000 tons/hour or more. Through multi-unit combined operation, they can fully meet the primary crushing needs of medium-sized and even large mines.

Q2: How is the reliability and durability of the equipment? How does it compare to fixed production lines?

A2: Professional mobile mining crushing equipment manufacturers have fully considered harsh working conditions in their designs. The core crusher, motor, and gearbox all utilize heavy-duty components of the same grade as those used in fixed production lines. Through reinforced chassis, high-quality wear-resistant materials, and robust steel structures, their reliability is comparable to fixed production lines, while retaining the advantages of mobility.

Q3: What are the main cost components of investing in a mobile crushing plant?

A3: The main costs include the initial equipment purchase cost, daily fuel/electricity consumption, replacement costs for wear parts (such as jaw plates, impact plates, and liners), and regular maintenance costs. Its overall cost advantage lies in the significant savings on infrastructure construction, relocation costs, and transportation costs, resulting in significant long-term economic benefits.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!