Mobile Jaw Crusher on Tracks

In today's mining and construction waste management industries, which prioritize high efficiency, environmental friendliness, and flexible production, tracked mobile jaw crushers have become indispensable core equipment. Representing a new direction in crushing technology, they perfectly combine a stationary jaw crusher with a fully self-propelled mobile chassis, creating a high-performance mobile crushing station integrating feeding, crushing, and conveying. This design completely changes the traditional crushing production line operation mode, which requires piling for fixed installation and incurs high infrastructure costs, enabling stone crushing operations to truly move with the raw materials, getting closer to the market.

Crawler Crusher PDF,Download ↓↓↓

What is a Tracked Mobile Jaw Crusher?

A tracked mobile jaw crusher, as the name suggests, is a jaw crusher mounted on a hydraulic tracked mobile chassis. Its core system mainly includes the following parts:

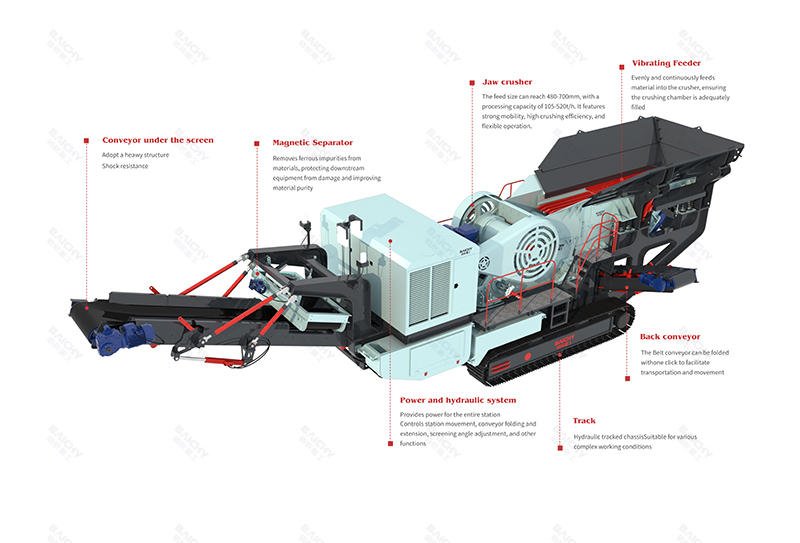

Structural diagram of tracked jaw crusher

• Feeding System: Typically includes a vibrating feeder, used to uniformly and continuously supply raw materials to the crusher host.

• Crusher Host: The core component, employing mature jaw crusher technology, responsible for the primary coarse crushing of large materials.

• Power System: Provides the power required for equipment operation, typically using a diesel engine or an external electric power source, adaptable to different operating scenarios.

• Tracked Walking System: A high-strength tracked mobile chassis gives the equipment strong terrain adaptability and self-movement capability, allowing for flexible relocation.

• Conveying System: Transports the crushed finished material to a designated stockpile.

Working Principle Overview

Material is poured into the feeder by an excavator or loader, pre-screened, and then evenly fed into the jaw crusher. The relative compression motion of the moving and fixed jaws crushes large pieces of material to the required particle size, and then the finished product is output via a belt conveyor. The entire mobile crushing plant can be remotely controlled for movement, steering, and adjustment, achieving integrated assembly line operation.

Significant Advantages of Tracked Mobile Jaw Crusher

Choosing a tracked mobile jaw crusher brings multiple advantages to your project:

Unparalleled Mobility and Flexibility

The tracked mobile design allows for rapid movement and positioning on the work site, and even rapid relocation between different construction sites. This significantly reduces equipment disassembly, assembly, and transportation time, making it particularly suitable for projects with complex operating conditions and dispersed work sites.

1. Significantly Reduced Operating Costs

It eliminates the need for fixed concrete foundation construction costs and long-distance material transportation to a fixed crushing line, thereby drastically reducing transportation and equipment installation costs. One piece of equipment constitutes a complete production line, realizing an economical model of bringing the production line to the material source.

2. Rapid Deployment and Highly Efficient Operation

The equipment can be put into production almost immediately upon arrival at the site, greatly shortening the project preparation cycle. Its integrated design ensures smooth material flow and improves overall crushing efficiency.

3. Strong Adaptability and Environmental Protection

The powerful tracked mobile chassis can adapt to rugged operating environments. Simultaneously, the equipment can be equipped with an advanced dust removal and noise reduction system, reducing environmental pollution and aligning with the concept of green production.

Successful Application Case

A large granite quarry previously used a fixed production line, resulting in high transportation costs and poor flexibility. After introducing our tracked mobile jaw crusher, on-site crushing was achieved, increasing output by approximately 30% and reducing overall operating costs by over 20%. The operating face can be easily adjusted, fully demonstrating the superior performance of the mobile crushing plant.

Related Equipment Recommendations

To meet the needs of different customers, we offer complete mobile crushing equipment solutions:

Tracked jaw crusher main unit comes with

• Tracked Mobile Cone Crusher: Suitable for medium and fine crushing operations, producing finished aggregates with excellent particle shape.

• Tracked Mobile Impact Crusher: Suitable for medium crushing, adept at handling medium-hard materials, producing finished products with excellent particle shape.

• Wheeled Mobile Crushing Plant: Suitable for plant areas with good road conditions, offering faster movement.

Frequently Asked Questions (FAQ)

1. What is the maximum feed size for the tracked mobile jaw crusher?

The maximum feed size depends on the specific model. Our equipment ranges from 500mm to over 1000mm. The appropriate model needs to be selected based on your raw material particle size and final output requirements.

2. What is the equipment's fuel consumption?

Fuel consumption is directly related to the hardness, density, and output requirements of the material being crushed. Our equipment utilizes highly efficient and energy-saving engines and optimized hydraulic systems to ensure strong power while keeping fuel consumption at a reasonable level. Specific data should be referred to the model's technical parameter table.

3. Is equipment maintenance complex?

No. Our tracked mobile jaw crusher is designed with easy-to-maintain features, such as a jaw plate replacement system and centralized lubrication points. We also provide detailed operation and maintenance manuals and global technical service support to ensure stable equipment operation.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!