In ore processing and construction aggregate production, crushing is a core process. Choosing the right crushing solution is crucial for project profitability, operational efficiency, and long-term success. As a manufacturer of mobile crushing equipment for the mining industry, we understand that the needs of different customers vary greatly. This article will provide an in-depth analysis of the characteristics and applicable scenarios of stationary crushing plants, and compare them with mobile solutions to help you make an informed decision.

I. In-depth Analysis of Stationary Crushing Plants: A Solid Foundation for Production

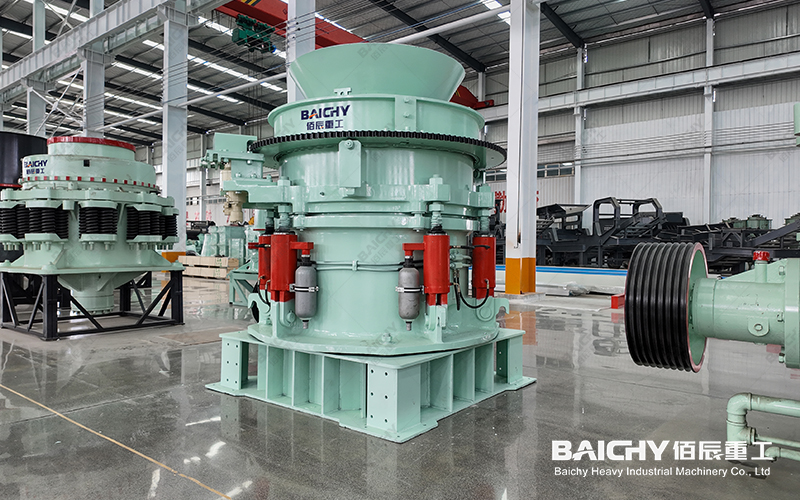

A stationary crushing plant, as the name suggests, has all crushing, screening, and conveying equipment permanently or semi-permanently installed on a fixed site. It typically consists of equipment such as jaw crushers, cone crushers, impact crushers, or sand making machines, connected by a complex belt conveyor system to form a complete production line.

Jaw Crusher

Hydraulic Cone Crusher

Impact Crusher

VSI Sand Making Machine

Core Features and Design Philosophy

Its design philosophy is to pursue "scale, stability, and durability." Once built, it becomes a production center that operates continuously for years or even decades. Its capacity can be designed to be very large, ranging from hundreds to thousands of tons per hour, to meet the long-term, stable supply needs of large mines, large aggregate yards, or large-scale construction projects.

| Key Words |

Stationary Crushing Plant |

| Product Model |

Stone Crushing Plant |

| Capacity |

0-2000t/h |

| Core Advantages |

Multi-stage fragmentation and reshaping |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

II. Why Choose a Stationary Crushing Plant? Analyzing its Irreplaceable Advantages

Although mobile crushing equipment offers high flexibility, stationary crushing plants have undeniable advantages in the following scenarios:

1. Unparalleled Capacity and Stability

Stationary plants have a solid foundation and efficient power transmission, enabling continuous, high-intensity operation 24 hours a day, achieving maximum output and optimal particle size control. This is the basis for achieving economies of scale.

2. Lower Unit Production Costs

In projects with fixed raw material sources and long mining cycles (usually more than 3-5 years), although stationary plants have higher initial investment costs, their lower operating energy consumption, more centralized maintenance, and the distribution of equipment wear costs over a huge output make the production cost per ton of aggregate highly competitive.

3. Highly Automated and Intelligent Integration

Fixed crushing plants are easy to integrate with advanced central control systems, dust collection systems, noise reduction systems, and automated monitoring systems, enabling "intelligent factory" management, significantly reducing labor requirements, and improving safety and environmental standards.

4. Product Form and Quality Control

Through carefully designed multi-stage crushing and screening processes, fixed crushing plants can more precisely control the particle size distribution and shape of the final product, producing high-quality aggregates of various specifications to meet the stringent requirements of the high-end construction market.

III. Typical Cases: Successful Applications of Fixed Crushing Plants

Case Study 1: Large-Scale Granite Aggregate Project

A large building materials group invested in a 20 million-ton per year aggregate production line in an area with abundant granite resources. They chose a fixed crushing plant consisting of a large jaw crusher, multiple cone crushers, and high-efficiency vibrating screens. Based on a stable mineral source and a highly automated production line, the project provides a long-term stable supply of high-quality aggregates to multiple key projects and commercial concrete plants in the surrounding area, resulting in a considerable return on investment.

Case Study 2: Pre-Crushing in Metal Mines

In large iron mines, the raw ore needs to be crushed to a certain particle size before entering the grinding and beneficiation process. The heavy-duty fixed crushing plant built here (usually using a gyratory crusher or a large jaw crusher) has a huge processing capacity and is the "bottleneck" of the entire beneficiation line; its stable operation directly affects the efficiency and output of all subsequent stages.

IV. How to Choose? Our Professional Recommendations

The choice between a fixed or mobile crushing plant should be based on a comprehensive assessment of the following factors:

Raw Material Characteristics and Reserves: Concentrated ore bodies, large reserves, and long mining life are the primary prerequisites for choosing a fixed plant.

Site Conditions: Sufficiently flat, stable, and spacious land is required for construction and material storage.

Investment and Cost Analysis: Conduct detailed CAPEX (initial investment) and OPEX (operating cost) calculations and compare long-term returns.

Environmental Protection and Policy Requirements: Fixed plants facilitate centralized investment in environmental protection facilities, complying with increasingly stringent environmental policies.

Our recommendation: If you operate a large-scale, long-term mining or aggregate project with fixed raw materials, and are pursuing maximum economies of scale and the lowest cost per ton, then investing in a technologically advanced and optimally configured fixed crushing production line is undoubtedly a wiser strategic choice.

V. Frequently Asked Questions (FAQ)

FAQ 1: How long does it take to build a fixed crushing plant?

From civil construction and equipment installation to commissioning and production, the construction period for a medium-sized fixed crushing plant usually takes 3 to 6 months, and larger, more complex projects may take longer. This needs to be fully considered in the project planning stage.

FAQ 2: How are environmental issues addressed in fixed crushing plants?

Modern fixed crushing plants can fully control dust, noise, and wastewater through measures such as fully enclosed plant buildings, installation of high-efficiency bag filters, setting up spray dust suppression systems, constructing sedimentation tanks for wastewater treatment, and using sound insulation materials. They can fully meet environmental requirements.

FAQ 3: As a mobile crushing equipment supplier, why do you also introduce fixed crushing plants?

We are committed to providing our customers with the most suitable overall solutions. Although our main business is mobile equipment, it is our responsibility to honestly analyze the advantages and disadvantages of each technology. For customers who are suitable for fixed crushing plants, we will also provide professional advice. Many projects can also adopt a "fixed plant + mobile plant" hybrid model in the later stages to balance core production with flexible handling of marginal materials.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!