Baichy Heavy Industry Global Customer Cases

In the fields of mining, building aggregate production, and large-scale engineering construction, stone crushing is the cornerstone of the entire production process. Inefficient, frequently malfunctioning, and substandard crushing equipment not only slows down project progress but also relentlessly erodes your profits. Faced with hard and varied ores and rocks, you need more than just a machine; you need a reliable, efficient partner that understands how to create value for you.

As a mining crushing manufacturer with 20 years of focused experience, we deeply understand the challenges you face. This article will share with you how to achieve a leap in production efficiency by choosing a truly high-efficiency crushing solution.

Stone Crushing Plant PDF, Download ↓↓↓

I. What is True High-Efficiency Crushing? More Than Just Output

Many customers simply equate high efficiency with high output. However, based on our 20 years of industry insights, true high efficiency is a comprehensive indicator across multiple dimensions:

• Time Efficiency: High throughput per unit of energy consumption, shortening production cycles.

• Economic Efficiency: Lower wear rates on vulnerable parts, longer equipment lifespan, less maintenance downtime, and overall reduced cost per ton. • Quality Efficiency: Produces high-quality finished materials with excellent particle shape, reasonable gradation, and controllable powder content, enhancing product market value.

• Operational Efficiency: Stable equipment operation, high degree of automation, and simple operation, reducing reliance on manpower and operational complexity.

Only when performing excellently in all four dimensions can it be called a truly efficient crushing solution.

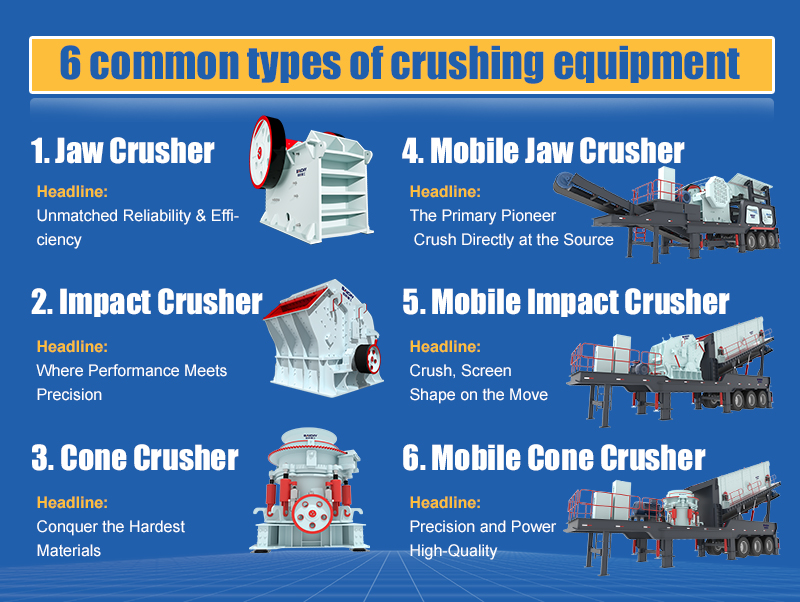

Baichy Heavy Industry's Hot-Selling Equipment

II. Core Advantages of Our Efficient Solution

After twenty years of R&D innovation and market validation, our stone crushers integrate the following core advantages to ensure superior value for our customers:

1. Robust and Durable Machine Structure: Designed and manufactured using high-quality, high-strength steel and advanced finite element analysis technology, the core structure of the equipment is more stable and can withstand long-term high-intensity impact loads, ensuring an ultra-long service life from the source.

2. Layered Crushing and Optimized Cavity Shape: For jaw crushers, cone crushers, and other equipment, we continuously optimize the crushing cavity design and deepen the application of the layered crushing principle. This not only significantly improves crushing efficiency and output, but also greatly reduces wear on vulnerable parts through the ingenious combination of stone-on-stone and stone-on-iron crushing.

3. Intelligent Hydraulic Control System: An advanced hydraulic system is used to adjust the discharge port, clear the chamber, and protect against iron ingress. When uncrushable materials (such as iron blocks) enter the chamber, the system automatically releases and resets, protecting the core components of the equipment from damage and greatly improving the safety and continuous operation capability of the equipment.

4. Targeted Solutions: There is no one-size-fits-all equipment, only the most suitable solution. We offer a full range of products, from jaw crushers and cone crushers to impact crushers (sand making machines). Our engineering team will conduct in-depth analysis of your raw material characteristics (such as hardness, moisture content, and mud content), expected output, and finished product requirements to recommend or customize the most suitable crushing and screening process and equipment combination for you.

III. Practical Application of High-Efficiency Solutions

From hard basalt and granite to medium-hard limestone and river pebbles, our equipment has performed excellently in numerous projects worldwide. For example, a major high-speed rail project's aggregate supplier, after using our multi-cylinder hydraulic cone crusher, not only saw a more than 30% increase in output, but also a 40% extension in the service life of core wear parts such as the crushing wall and jaw wall. The annual savings in spare parts costs and downtime brought considerable economic benefits to the company.

In the stone crushing industry, experience is invaluable. 20 years of focus have given us a deep understanding of how to manufacture equipment that is not only robust but also intelligent and economical. We offer not just a single crusher, but a comprehensive solution designed to reduce your cost per ton, enhance product competitiveness, and achieve long-term profitability.

Contact our expert team today for free technical consultation and solution design tailored to your project! Let us use 20 years of expertise to help you succeed.