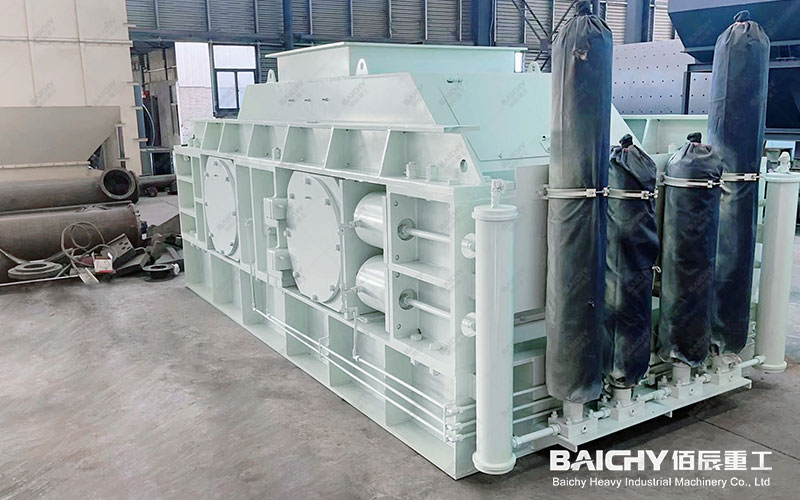

Double Roller Crusher Manufacturer

Double roll crushers, as a key piece of equipment in the mining crushing field, utilize two counter-rotating rollers to compress, split, and grind materials, thereby achieving medium and fine crushing operations.

With the continuous improvement of production efficiency, finished product particle shape, and energy consumption requirements in the mining industry, double roll crushers, due to their relatively simple structure, less over-crushing, and uniform product particle size, have occupied an irreplaceable position in industries such as coal, metallurgy, building materials, and chemicals.

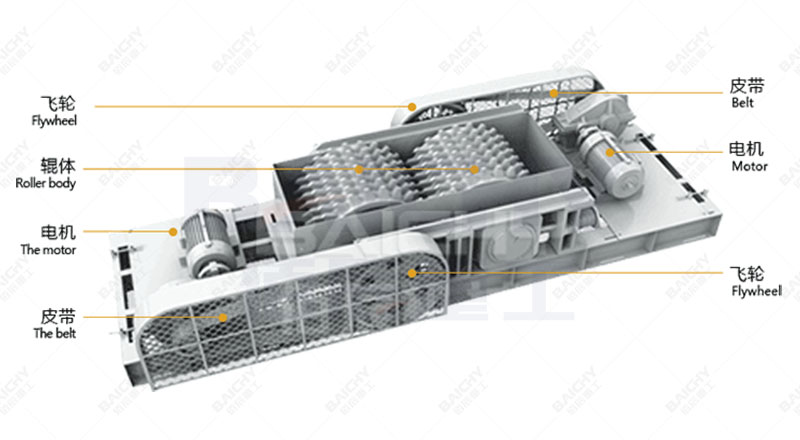

What is a double roll crusher?

A double roll crusher mainly consists of a frame, two crushing rollers, a transmission device (motor, pulleys, gears), and a spring or hydraulic adjustment device. During operation, the two rollers rotate in opposite directions. The material falling between the two rollers is drawn into the crushing chamber by friction and gravity, and is continuously crushed by compression and shearing forces, finally being discharged from the gap between the two rollers. The discharge particle size can be flexibly controlled by adjusting the gap between the two rollers.

Structure diagram of a double-roll crusher

Core Advantages: Why Choose Our Double Roll Crusher?

With twenty years of technological accumulation and process innovation, our manufactured double roll crushers possess the following significant advantages:

1. High Efficiency and Energy Saving, Controllable Costs: Optimized tooth profile design and roller surface material result in a large crushing ratio and significantly reduced energy consumption per unit of output, directly saving operating costs for customers.

2. Uniform Discharge, Low Over-Crushing Rate: The unique layered crushing principle effectively controls the product particle size, ensuring that most of the finished product is within the predetermined size range, making it particularly suitable for applications with strict requirements on product particle size.

3. Robust Structure, Easy Maintenance: Heavy-duty frame and high-quality bearings provide strong load-bearing capacity. Modular design allows for quick replacement of wear parts, greatly reducing downtime for maintenance.

4. Intelligent Adjustment, Stable Operation: Optional hydraulic or spring adjustment devices can automatically compensate for wear and protect the equipment from damage caused by unbreakable objects such as iron blocks, ensuring safe and stable operation.

5. Wide Adaptability, Flexible Application: Can process a variety of materials with medium to low hardness, such as coal, coke, limestone, slag, etc., offering wide applicability.

Double-roll crusher customer site

Case Study: Successful Application Scenario Sharing

We supplied several large double-roll crushers to a large building materials group in North China for their limestone crushing production line. The client's original equipment produced excessive fine powder in the finished product, affecting the quality of downstream sintering. Our solution involved using double-roll crushers with specially designed wear-resistant alloy roller shells and precisely adjusting the roller gap and speed. As a result, the proportion of qualified particle size (10-30mm) in the production line's output increased by over 25%, the amount of over-crushed material decreased by approximately 40%, and annual equipment maintenance costs were reduced by 15%, earning high praise from the client. This fully demonstrates our capabilities as a seasoned manufacturer providing mining crushing equipment solutions.

Related Equipment Recommendations

| Double-roll sand making machine | Suitable for finer sand making requirements, an extension of double-roll crusher technology. |

| Jaw crusher | An ideal primary crushing equipment, which can be combined with a double-roll crusher to form an efficient two-stage crushing system. |

| Vibrating feeder and vibrating screen | Used in conjunction to achieve uniform feeding and finished product classification, improving overall production line efficiency. |

Frequently Asked Questions (FAQ)

Q: What materials can double-roll crushers mainly crush?

A: Suitable for materials with medium to low hardness and low abrasiveness, such as coal, limestone, gypsum, clay, slag, coke, etc., it is one of the widely used models in mining crushing equipment.

Q: How to control the output particle size?

A: This is mainly achieved by adjusting the gap between the two rollers. The larger the gap, the coarser the output; the smaller the gap, the finer the output. Our equipment is equipped with a convenient adjustment mechanism.

Q: How to handle roller shell wear?

A: The roller shells are made of high-strength wear-resistant materials and are designed to be replaceable. When wear affects the output particle size, they can be easily replaced, which is a major part of routine maintenance.

Q: What are the advantages of double-roll crushers compared to hammer crushers and jaw crushers?

A: Compared to hammer crushers, it produces less fine powder and has a better particle shape; compared to jaw crushers, it offers more uniform product particle size and sometimes more advantageous energy consumption in small to medium-scale fine crushing operations. The specific model selection needs to be determined based on material characteristics and production requirements.

Q: Can you provide customized solutions?

A: Absolutely. With 20 years of design and manufacturing experience, we can provide customized mining crushing equipment solutions, from single machines to complete production line layouts, based on the client's specific materials, production requirements, and site conditions.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.