What is a direct rotary dryer?

Direct rotary dryer is a highly efficient continuous drying equipment widely used in chemical, food, mining, pharmaceutical and other industries. It directly contacts the wet material through high-temperature airflow, quickly evaporates water, and achieves large-scale and uniform drying. Compared with indirect drying methods (such as steam heating), direct drying has the advantages of high thermal efficiency, large processing capacity, and low energy consumption. It is especially suitable for drying granular, powdered or filter cake materials.

Core features

✔ Efficient heat transfer: hot air directly contacts the material and dries quickly.

✔ Continuous operation: automatic feeding, drying, and discharging, suitable for industrial production.

✔ Energy saving and environmental protection: hot air recycling, reducing energy consumption and reducing waste gas emissions.

✔ Strong adaptability: adjustable temperature and wind speed to adapt to materials with different humidity and viscosity.

Working principle of direct rotary dryer

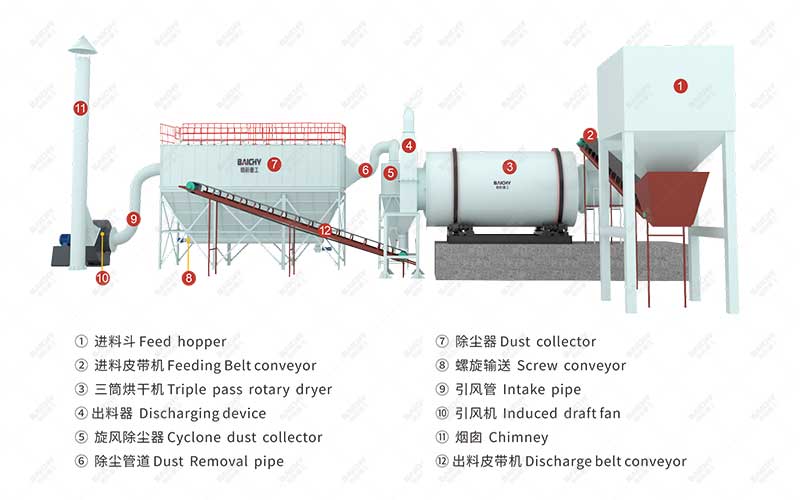

The core structure of the direct rotary dryer includes a rotating cylinder, a hot air system, a feeding device, a discharging device, etc. The working process is as follows:

1. Feeding stage: wet materials enter the rotating cylinder through a screw conveyor or a belt conveyor.

2. Drying stage: high-temperature airflow (usually generated by gas, fuel oil or electric heating) flows in the opposite or same direction as the material, directly transferring heat to evaporate moisture.

3. Rotating stirring: a lifting plate or a lifting plate is installed inside the cylinder to continuously turn the material to ensure uniform heating.

4. Discharging stage: the dried material is discharged from the discharge port, and the exhaust gas is discharged or recycled after dust removal.

Direct rotary dryer vs. indirect rotary dryer

| Comparison items | Direct rotary dryer | Indirect rotary dryer |

| Heat transfer method | Hot air directly contacts the material | Steam/thermal oil indirect heating |

| Thermal efficiency | High (70%-90%) | Low (50%-70%) |

| Applicable materials | Powder, granular | Heat-sensitive, easily oxidizable materials |

| Energy consumption | Low | High |

| Equipment cost | Moderate | High |

How to choose?

• If the material allows direct contact with hot air and pursues high efficiency and low cost, the direct rotary dryer is an ideal choice.

• If the material is easily oxidized and highly heat-sensitive (such as certain drugs and foods), indirect drying is more suitable.

How to optimize the performance of the direct rotary dryer?

1. Control the humidity of the feed: Too high humidity may lead to incomplete drying, and pretreatment (such as centrifugal dehydration) is recommended.

2. Adjust the hot air temperature: The optimal drying temperature for different materials is different and needs to be determined through experiments.

3. Optimize the drum speed: The speed affects the residence time of the material. Too fast will lead to insufficient drying, and too slow will reduce efficiency.

4. Regular maintenance: Clean the lifting plate and check the sealing to avoid hot air leakage affecting efficiency.

Common faults and solutions

• Uneven drying → Check whether the lifting plate is damaged and adjust the speed.

• Excessive energy consumption → Optimize the hot air circulation system to reduce heat loss.

• Dust pollution → Install a bag filter or wet dust removal device.

How to choose a suitable direct rotary dryer?

1. Determine the material characteristics (humidity, viscosity, thermal sensitivity).

2. Calculate the capacity requirements (hourly processing volume).

3. Select the heat source (electricity, gas, fuel oil or steam).

4. Investigate the manufacturer's qualifications (whether customization and after-sales support are provided).

Contact us

If you need a direct rotary dryer solution, please consult Baichy Heavy Industry. We provide:

✔ Professional selection guidance

✔ Non-standard customization service

✔ 24-hour after-sales support

Tel: 0086 15093222637 | Official website: http://www.baichychina.com