Barite, as an important non-metallic mineral raw material, has wide applications in oil drilling, chemical industry, and filler applications. With the increasing market demand for high-purity, fine-grained barite powder, building a high-yield, stable, and energy-efficient grinding production line has become a popular choice for many investors.

This article will focus on the classic production capacity of 50 tons per hour, deeply analyzing the core components and best practices of a barite grinding production line, providing you with a detailed investment and construction reference.

I. Core Process Flow of a 50-Ton-per-Hour Barite Grinding Production Line

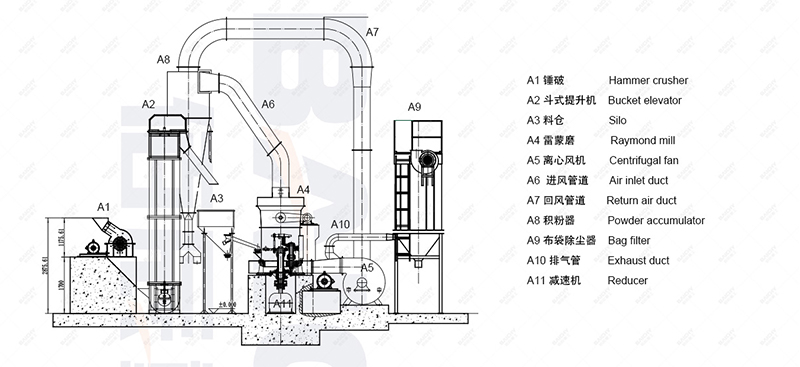

An efficient production line cannot exist without scientific process design. The barite grinding process for a 50-ton-per-hour production line typically includes the following key stages:

1. Coarse Crushing Stage: Large pieces of barite ore are evenly fed into a jaw crusher via a vibrating feeder for preliminary crushing, breaking the material to a particle size (usually less than 10cm) suitable for the next process.

2. Intermediate Storage and Feeding: The crushed material is conveyed to the intermediate silo by a bucket elevator, and then fed into the grinding mill at a stable and controllable flow rate via an electromagnetic vibrating feeder. This is crucial for ensuring stable mill operation and uniform product fineness.

3. Grinding Core Process: This is the "heart" of the entire production line. The material is ground into powder within the grinding mill. For a scale of 50 tons per hour, large vertical grinding mills or European-style Raymond mills are the mainstream choice, offering advantages such as high efficiency, low energy consumption, and a wide product adjustment range.

4. Classification Process: The ground powder enters the classifier for classification via airflow. Unqualified coarse powder is returned to the mill for regrinding, while qualified fine powder proceeds to the next stage.

5. Collection and Finished Product Storage: Qualified powder is collected by a high-efficiency pulse bag filter, converged via a screw conveyor or air chute, and finally sent to the finished product silo by the finished product conveying system, ready for packaging or bulk shipment.

6. Dust Control and Environmental Protection: Dust collection devices are installed at all dust-generating points along the entire production line, including crushing, conveying, grinding, and packaging, ensuring a clean production environment that meets environmental protection requirements.

II. Core Equipment Selection Recommendations (50-ton/hour configuration)

Equipment selection directly determines the production line's capacity, finished product quality, and operating costs.

• Jaw Crusher (Coarse Crushing): It is recommended to use a deep-cavity jaw crusher of PE-600×900 or larger to ensure primary crushing capacity.

• Grinding Mill (Core):

◦ Option A (Vertical Mill): It is recommended to use vertical grinding mills such as LM170K or MLS2650. Advantages: Low energy consumption (20-30% less energy than Raymond mills), low noise, can directly dry and pre-grind, suitable for large-scale, intensive production.

◦ Option B (European-style Mill): It is recommended to use European-style Raymond mills such as 5R4128 or MTW175. Advantages: Mature technology, convenient maintenance, relatively lower investment cost compared to vertical mills, and flexible adjustment of finished product fineness between 80-600 mesh.

• Classifier: High-efficiency turbine classifier matched with the grinding main unit to ensure sorting accuracy and efficiency.

• Dust Collection System: Must be equipped with a large pulse bag dust collector; the air volume must be matched with the system, and the dust collection efficiency reaches over 99.9%.

• Conveying and Feeding System: Adopts a sealed elevator, vibrating feeder, and airlock feeder to reduce dust and ensure continuous and stable feeding.

III. Key Advantages of the Production Line

• High Output and High Efficiency: Optimized equipment configuration and process flow ensure a stable production capacity of 50 tons per hour.

• Energy Saving and Environmental Protection: Adopts advanced grinding technology and a high-efficiency dust collection system, resulting in low energy consumption per unit product and dust emissions far below national environmental protection standards.

• Superior Finished Product Quality: The finished powder has uniform fineness (usually adjustable between 150-400 mesh), high purity, and good market competitiveness. • High degree of automation: A PLC central control system can be adopted, enabling one-button start/stop, remote monitoring, and fault alarms, reducing labor costs and improving operational safety.

IV. Investment Considerations and Conclusion

Investing in a 50-ton-per-hour barite grinding production line is a complex undertaking, requiring comprehensive consideration of equipment costs, plant infrastructure, power configuration, installation and commissioning, and subsequent operation and maintenance. We recommend that investors communicate thoroughly with professional equipment suppliers to tailor the most economical and reasonable solution based on specific raw material characteristics, finished product requirements, and budget.

Choosing a technologically advanced and stable production line is a strong guarantee for winning market competition in the barite deep processing field. We hope this article provides valuable reference for your project planning.