In the world of mineral processing, efficiency and cost are eternal themes. There is a device that, without relying on a complex power source, can efficiently separate valuable minerals from gangue solely based on the fundamental principles of gravity and fluid dynamics—this is the spiral sluice.

As a classic and still widely used gravity separation device, it plays an irreplaceable role in the beneficiation of various minerals such as iron ore, tungsten ore, and tin ore.

I. How does a spiral sluice work? Unveiling its core separation principle

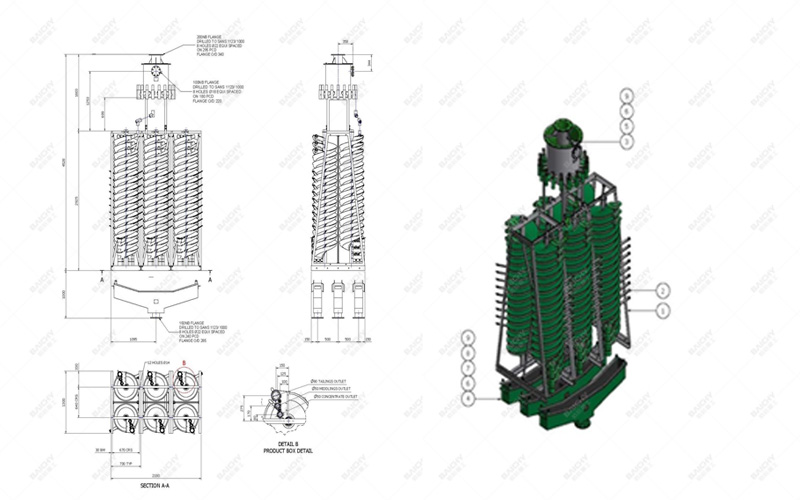

The separation process of a spiral sluice is a sophisticated "mineral marathon." Its core principle lies in utilizing the differences in density, particle size, and shape between mineral particles to create different trajectories within the thin film of water flow in the spiral sluice, thereby achieving separation.

1. Feeding: The slurry (a mixture of mineral particles and water) is uniformly fed to the top feed port of the spiral sluice.

2. Flow and Segregation: Under the influence of gravity, the slurry flows downwards along the spiral channel. During the flow process, mineral particles of different properties begin to "differentiate": denser, smaller heavy mineral particles settle quickly and tend towards the inner edge of the sluice; while lighter, larger light minerals (gangue) are pushed towards the outer edge by the water flow.

3. Cutting and Collection: At the bottom of the sluice, a separator or interceptor is installed. By adjusting the position of the separator, the stratified heavy mineral products from the inner edge, the mineral products from the middle zone, and the light mineral tailings from the outer edge can be precisely collected, completing the entire sorting process.

II. Why Choose a Spiral Sluice? Its Significant Advantages at a Glance

• No Power Consumption: Relying entirely on gravity flow, energy consumption is extremely low, resulting in significant operating cost advantages.

• Simple Structure and Easy Maintenance: The equipment mainly consists of a spiral sluice and a support frame, resulting in a low failure rate and minimal daily maintenance workload.

• Large Processing Capacity and High Sorting Efficiency: A single unit can process a large amount of slurry, making it particularly suitable for pre-selection operations or the sorting of coarse-grained minerals.

• Environmentally friendly and highly adaptable: The separation process requires no chemical reagents, making it environmentally friendly and adaptable to fluctuations in feed concentration and particle size.

III. Main Application Areas: Beyond Traditional Mines

The spiral sluice has a wide range of applications, mainly including:

• Ferrous metal ores: Such as the separation of hematite, limonite, and manganese ore.

• Non-ferrous metal ores: Such as the enrichment of tungsten, tin, tantalum, and niobium placer deposits.

• Rare metal ores: Such as the recovery of zircon, rutile, and monazite from coastal placer deposits.

• Non-metallic minerals: Such as the purification of quartz sand, a raw material for glass production.

• Tailings reprocessing: Recovering valuable components from old tailings ponds to achieve comprehensive resource utilization.

IV. How to Correctly Select and Operate?

Selecting the appropriate spiral sluice is key to ensuring separation efficiency. The following should be considered during selection:

• Mineral properties: The density difference between the target mineral and the gangue is crucial; the greater the density difference, the better the separation effect.

• Processing Capacity Requirements: Determine the diameter and number of heads of the spiral slurry based on the hourly slurry volume to be processed.

• Feed Size: Spiral slurries are optimal for separating coarser particles (typically 1-0.03 mm).

Maintaining stable feed concentration and feed rate is crucial for achieving ideal performance indicators. Regularly inspecting the slurry for wear and keeping it clean is also essential.

With its simplicity, efficiency, and economy, the spiral slurry continues to hold an important place in modern mineral processing. Whether used as the primary separator or as an auxiliary pre-selection device, it is a powerful tool for reducing production costs and improving economic efficiency. Understanding its principles and correctly selecting and applying it will undoubtedly bring significant value to your mineral processing business.