Ball mills are widely used grinding equipment in mining, building materials, chemical and other industries, and the choice of grinding media directly affects grinding efficiency, energy consumption and product quality. How to choose the right grinding media? Which is better, steel balls, ceramic balls or zirconia balls? How to calculate the media size and filling rate? This article will comprehensively analyze the key points of ball mill grinding media selection to help you optimize the grinding process and reduce production costs.

1. Comparison of common materials and advantages and disadvantages of grinding media

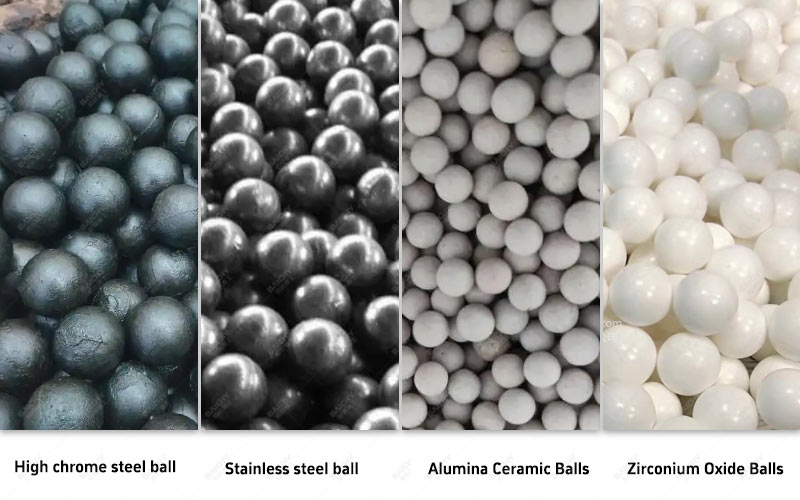

The material of the grinding media directly affects wear resistance, grinding efficiency and pollution risk. The following is a comparison of the characteristics of several common materials:

| Material type | Advantages | Disadvantages | Applicable scenarios |

| High chromium steel ball | Strong wear resistance, moderate cost, high impact force | Easy to rust, possible contamination of materials | Metal mines, cement, metallurgical industries |

| Stainless steel ball | Corrosion resistance, low pollution | Higher cost, slightly poor wear resistance | Food, medicine, chemical industry |

| Alumina ceramic ball | Corrosion resistance, no pollution, low density | Fragile, weak impact force | Non-metallic minerals, electronic materials, fine chemicals |

| Zirconium oxide ball | Ultra-high wear resistance, corrosion resistance, long life | Expensive |

High value-added industries (such as lithium batteries, electronic ceramics) |

Selection suggestions:

• Metal mine/cement industry: High chromium steel balls are preferred, taking into account wear resistance and cost.

• Food/pharmaceutical industry: Stainless steel balls or ceramic balls are recommended to avoid metal contamination.

• High-precision grinding (such as lithium battery materials): Zirconia balls are the best. Although the cost is high, it is more economical for long-term use.

2. How to choose the size of grinding media?

The size of the media directly affects the grinding efficiency and product fineness. The basic principles are as follows:

• Coarse-grained materials (such as primary crushing of ore) → Large diameter media (Φ50-100mm)

• Medium fineness (such as cement clinker) → Medium size (Φ20-50mm)

• Ultrafine powder (such as nanomaterials) → Small diameter media (Φ1-10mm)

Precautions:

• Too small media size → Low grinding efficiency and increased energy consumption.

• Too large media size → Too strong impact force, which may damage the liner or excessive wear.

3. Calculation and optimization of grinding media filling rate

The filling rate (the proportion of the media to the cylinder volume) directly affects the grinding efficiency and energy consumption.

Standard filling rate range:

• Dry grinding: 30%-45%

• Wet grinding: 40%-50%

Optimization suggestions:

• Filling rate is too low (<30%): low grinding efficiency and high energy consumption.

• Filling rate is too high (>50%): medium movement is restricted, which can easily lead to "dead zone" and reduce grinding effect.

• Optimum filling rate: usually controlled at around 40%, which can be adjusted through experiments.

4. How to extend the service life of grinding media?

✔ Check wear regularly: replace broken or severely deformed media in time.

✔ Optimize liner matching: The shape of the liner affects the movement trajectory of the media, and choosing a suitable corrugated liner can reduce wear.

✔ Control the feed particle size: Too large particles will increase the impact wear of the media.

✔ Avoid overfilling: Too high a filling rate will increase the friction loss between the media.

5. FAQs

Q1: Which is better for wet grinding, ceramic balls or steel balls?

A: Ceramic balls are more corrosion-resistant and suitable for wet grinding; but steel balls have stronger impact and are suitable for high-hardness materials.

Q2: How to determine whether the grinding media needs to be replaced?

A: When the media wear exceeds 10%-15% (diameter reduction) or a large amount of breakage occurs, it should be replaced in time.

Q3: Why are zirconia balls so expensive? Is it worth using?

A: The life of zirconia balls is 5-10 times that of steel balls. In the long run, it can reduce the replacement frequency and downtime costs, and is suitable for high value-added industries.

Selecting the right ball mill grinding media requires comprehensive consideration of factors such as material properties, grinding fineness, and cost budget. By optimizing the material, size, and filling rate, the grinding efficiency can be significantly improved, and energy consumption and wear costs can be reduced. If you need a more accurate selection calculation tool, please contact us for professional support!

Further reading: