Why do we need to deeply understand the structure of ball mills?

As the "heart equipment" of the mining, cement and metallurgical industries, the structural design of ball mills directly affects the crushing efficiency, energy consumption and maintenance costs. A key data proves that the energy consumption of ball mills with optimized structures can be reduced by 15-30%. This article will take you to disassemble each core component to help you achieve efficient operation of the equipment.

Detailed explanation of the five core structural components of the ball mill

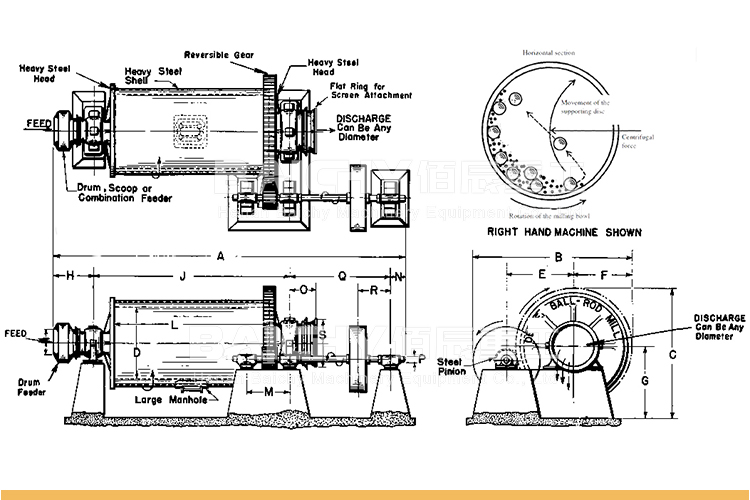

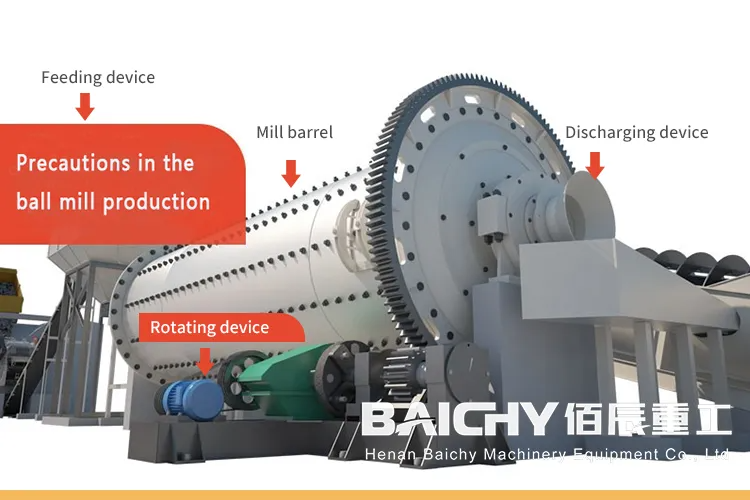

1. Cylinder system

• Structure: Steel plate rolled and welded cylindrical shell (thickness ≈ 50-150mm)

• Core design: Aspect ratio (L/D) 1.5-2.5 (directly affects the material retention time)

• Special process: Conical end cap design at both ends to reduce stress concentration

2. Wear-resistant lining

| Type | Material | Applicable scenarios | Life cycle |

| Corrugated lining | High manganese steel | Coarse grinding impact area | 6-12 months |

| Step lining | Chrome-molybdenum alloy steel | Fine grinding area efficiency improvement | 12-18 months |

| Rubber lining | Composite rubber | Wet mill anti-corrosion | 24 months + |

3. Bulkhead (key partition component)

Function: Separate the coarse/fine grinding bins and optimize the grinding gradation

Design features: The grate width is customized according to the material particle size (usually 5-15mm)

Inlet and outlet device

• Feeding end: Combined feeder (screw + fan valve) to prevent backflow

• Discharging end: forced discharge by grating plate vs overflow gravity discharge

Working principle: How does the structure drive grinding efficiency?

1. Kinematic analysis

Critical speed formula: n₀ = 42.3/√D (D=cylinder inner diameter in meters)

Actual operating speed: 65%-78% critical speed (produces waterfall grinding)

2. Three stages of grinding media movement:

• Sliding zone (bottom layer): extrusion crushing

• Drop zone (middle layer): impact crushing

• Centrifugal zone (failure zone): need to be avoided

Dry VS wet ball mill: full comparison of structural differences

| Structural parts | Dry ball mill | Wet ball mill |

| Cylinder seal | Pneumatic sealing system | Mechanical seal + rubber gasket |

| Discharge method | Wind negative pressure extraction | Slurry overflow/grating forced discharge |

| Anti-corrosion design | Ordinary anti-rust paint | Rubber lining + 316 stainless steel parts |

| Special structure | Hot air duct | Pressure relief explosion-proof hole |

Structural optimization and maintenance practical guide

Key measures to extend service life

Liner bolt preload control: hydraulic torque wrench (±5% error)

Gear pair meshing calibration: laser centering instrument accuracy ≤ 0.05mm/m

High-frequency fault structure point checklist

| Failure phenomenon | Structural cause | Solution |

| Cylinder abnormal sound | Liner falling off/bolt breaking | Install stress sensor monitoring |

| Gearbox vibration | Gear ring radial runout tolerance | Dynamic balance correction |

| Bearing overheating | Seal failure causing dust intrusion | Transformation of labyrinth seal system |

Selection must-read: Structural selection matching process

Quick selection formula based on processing volume:

Cylinder volume V = (Q×t)/(60×φ×q)

Q: output (t/h), t: grinding time (min), φ: filling rate (0.3-0.45), q: unit power consumption (kWh/t)

Three principles of structural selection:

1. High hardness material → Select stepped lining + small steel ball grading

2. Flammable and explosive scenarios → wet structure + nitrogen protection system

3. Large mining projects → dual-drive synchronous motor configuration (power ≥ 4500kW)

Understanding the structure of the ball mill is not only the basis of equipment management, but also the core competitiveness of improving efficiency and reducing costs. The practical skills mentioned in this article, such as the gear meshing calibration method and wet mill anti-corrosion process, have achieved a 37% reduction in the annual maintenance cost of a single device in a copper mine project (data source: Journal of the Chinese Society of Nonferrous Metals 2023).