What is the difference between a tube mill and a ball mill? A comprehensive comparison of structures and applicable scenarios

In industries such as mining, cement, and ceramics, tube mills and ball mills are both common grinding equipment, but they differ significantly in structure, working principle, and application scenarios. This article will compare the differences between the two in detail to help you choose the right equipment based on your actual needs.

1. Core difference comparison

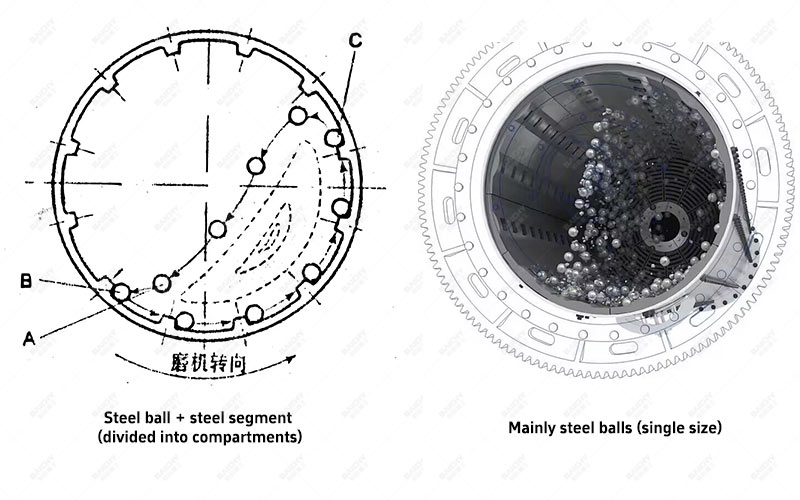

1.1 Different structural designs

| Comparison items | Tube mill | Ball mill |

| Aspect ratio | Length much greater than diameter (usually ≥3:1) | Length close to diameter (usually ≤2:1) |

| Internal structure | Compartment design (coarse grinding compartment + fine grinding compartment) | Single compartment or simple compartment |

| Grinding media | Steel balls + steel segments (compartment ratio) |

Summary:

• Tube mills have a more complex structure and are suitable for fine grinding;

• Ball mills have a simpler structure and are suitable for coarse grinding or mixed grinding.

2.1 Different application scenarios

| Equipment | Applicable industries | Typical uses | Finished product particle size |

| Tube mill | Cement, ceramics, chemicals | Fine grinding (such as cement clinker, slag powder) | below 80μm |

| Ball mill | Mineral processing, metallurgy, building materials | Coarse grinding (such as ore crushing, raw material mixing) | 0.1-50mm |

Summary:

• Tube mill is suitable for high-precision grinding, such as cement ultrafine powder preparation;

• Ball mill is suitable for primary crushing or mixed grinding of ore, such as gold ore processing.

3. Comparison of energy consumption and efficiency

| Comparison items | Tube mill | Ball mill |

| Energy consumption | Higher (fine grinding requirement) | Lower (high coarse grinding efficiency) |

| Grinding efficiency | More uniform finished product, but lower output | High output, but coarser particle size |

| Maintenance cost | Complex structure, high maintenance cost | Simple structure, easy maintenance |

Summary:

• If you pursue high fineness, choose a tube mill;

• If you pursue high-yield coarse grinding, choose a ball mill.

How to choose a suitable mill?

1. Choose according to material characteristics

High hardness, need fine grinding (such as cement, slag) → Tube mill

Normal hardness, need coarse grinding (such as gold ore, iron ore) → Ball mill

2. Choose according to production capacity requirements

Small-scale fine production → Tube mill

Large-scale coarse grinding production → Ball mill

3. Choose according to investment budget

Sufficient budget, pursuit of high precision → Tube mill

Limited budget, pursuit of high output → Ball mill

Both mills and ball mills have their own advantages. When choosing, you need to comprehensively consider the material characteristics, production capacity requirements, energy consumption and cost:

✔ Tube mill: suitable for high-fineness grinding (cement, ceramics and other industries);

✔ Ball mill: suitable for high-yield coarse grinding (ore dressing, metallurgy and other industries).

If you are not sure how to choose, please consult our technical team, we will recommend the most suitable equipment according to your needs!

Further reading:

What Are the Differences between Dry and Wet Type Ball Mill?