Vertical Shaft Impact Crusher (VSI) Manufacturer | Global Solutions

In the mining, building materials, infrastructure construction, and renewable resource recycling industries, crushing equipment is at the core of the production process. As a manufacturer of mining crushing equipment with 20 years of professional experience, we deeply understand that efficient, reliable, and energy-saving crushing solutions are crucial to customer success.

Vertical Shaft Impact Crusher (VSI), with its unique working principle and superior performance, has become the ideal choice for material crushing and shaping processes in many industries.

Product Overview

The vertical shaft impact crusher is a high-efficiency crushing device that uses the stone-on-stone or stone-on-iron principle. Material gains kinetic energy in the high-speed rotating rotor and is thrown into the crushing chamber to collide with the liner or other materials, thereby achieving crushing and shaping. Compared with traditional jaw crushers and cone crushers, VSI crushers are better at producing cubic particles with excellent particle shape and reasonable gradation, especially suitable for manufactured sand production and aggregate shaping.

Core Product Advantages

1. Superior Particle Shape Quality: The produced finished material particles are cubic with low needle-like and flaky content, improving the strength and workability of concrete and asphalt mixtures.

2. High Efficiency and Energy Saving: The unique crushing principle results in higher energy utilization, greater output per unit of energy consumption, and significantly reduced operating costs.

3. Multifunctional Applications: By adjusting rotor speed, feeding method, and chamber design, it can easily handle the crushing of materials ranging from hard ores to medium-hardness materials (such as limestone and river pebbles) and recycled aggregates from construction waste.

4. Flexible Stone-on-Stone and Stone-on-Iron Configurations: Stone-on-Stone is suitable for crushing and shaping highly abrasive materials, reducing wear; Stone-on-Iron is suitable for sand making operations requiring higher crushing ratios and materials with medium to low abrasiveness.

5. Easy Maintenance and Long Service Life: The modular design makes core components (such as rotors and liners) easy to replace. The use of high-quality wear-resistant materials and an advanced throwing head design significantly extends the equipment's service life.

6. Environmental Protection and Automation: The equipment operates with low vibration and low noise, and the sealed structure effectively controls dust. It can be easily integrated into an automated control system for intelligent monitoring and remote operation and maintenance.

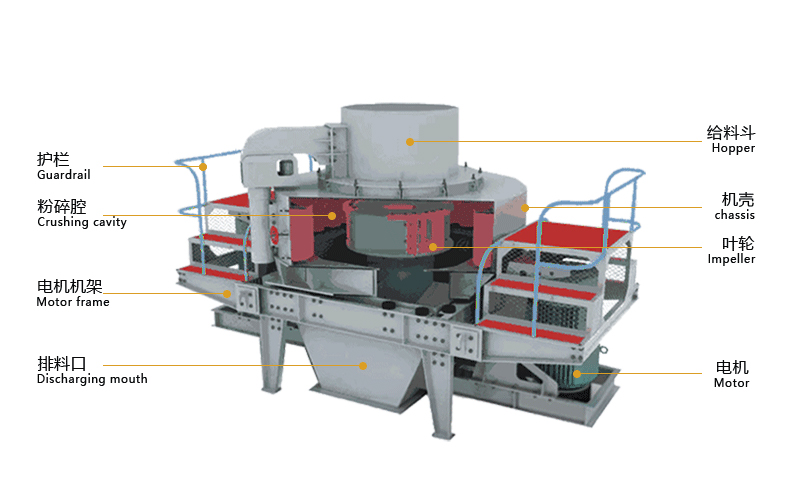

Vertical shaft impact crusher structure diagram

Wide Range of Applications

• Mining: Used for fine crushing of iron ore, copper ore, gold ore, bauxite, etc., providing ideal feed for subsequent grinding processes.

• Building Materials and Aggregate Production: Core equipment for producing high-quality manufactured sand and construction aggregates (0-5mm, 5-10mm, 10-20mm), meeting the stringent requirements of high-grade concrete and asphalt pavement aggregates.

• Infrastructure Construction: Provides high-quality sand and gravel aggregates for highways, railways, airports, dams, and other projects.

• Industrial Mineral Processing: Used for crushing and shaping materials such as quartz, feldspar, and silicon carbide.

• Solid Waste Resource Utilization: Efficiently crushes construction waste and concrete waste to produce recycled aggregates, achieving a circular economy.

Vertical shaft impact crusher customer site

Global Project Cases

Our vertical shaft impact crushers have successfully served numerous major projects worldwide:

• A large granite aggregate project in Southeast Asia: Two high-capacity VSI crushers were configured for the client for sand production. The finished sand particles were rounded, with continuous gradation and controllable modulus, completely replacing natural sand and meeting the needs of local large-scale commercial concrete plants and key projects.

• A limestone cement raw material project in the Middle East: Our VSI crushers were used for fine crushing of limestone, optimizing the feed particle size of the raw material mill, significantly increasing mill output and reducing overall power consumption.

• A construction waste recycling project in Europe: Using specially designed wear-resistant parts and dustproof design, construction waste was successfully crushed into high-quality recycled aggregate for use in the base layer of new roads, achieving a win-win situation for both economic and environmental benefits.

Frequently Asked Questions (FAQ)

Q: What are the main differences between vertical shaft impact crushers and cone crushers in the fine crushing stage?

A: Cone crushers mainly rely on interlayer crushing and are suitable for medium and fine crushing of hard rock, with generally lower product particle shape. VSI crushers utilize impact energy, excelling at crushing and shaping, and are particularly suitable for producing cubic particles and high-quality manufactured sand. However, they are more sensitive to material moisture content.

Q: What is the lifespan of the wear parts? Is replacement complicated?

A: We use high-strength composite ceramics or high-quality alloy wear-resistant materials, ensuring a long service life. The equipment adopts a modular design; key wear-resistant parts such as the discharge head and liners can be replaced from the side or top of the equipment without disassembling the main structure, making maintenance simple and quick.

Q: Can it handle wet, sticky materials?

A: For sticky materials with high moisture content, pre-screening or drying before feeding is recommended to prevent material from sticking in the crushing chamber and feed hopper, affecting throughput and equipment performance.

Q: How to control the fineness modulus and stone powder content of the finished sand?

A: By adjusting the rotor speed, feed rate, and the ratio of cascade feed to center feed, and in conjunction with a high-efficiency air screen or classifier, the fineness modulus of the finished sand can be precisely controlled, and the stone powder content can be stabilized within the ideal range (e.g., 10%-15%).

Q: What kind of support can your company provide?

A: As a manufacturer with 20 years of experience, we provide comprehensive services from site surveys, process design, equipment selection, installation and commissioning, operation training to lifetime after-sales support, ensuring successful project operation.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.