In numerous fields such as mining, aggregate production, and construction waste recycling, we often hear the resounding name of the jaw crusher. With its robust structure, powerful crushing capacity, and wide applicability, it is hailed as a pioneer in the crushing industry.

However, an isolated jaw crusher cannot independently complete the entire mission of transforming raw boulders into qualified aggregates. It requires an efficient and coordinated "team" to support it—this is the jaw crusher production line we will explore in depth today. This article will provide a comprehensive analysis of the core components, workflow, advantages, and key design aspects of this production line.

I. What is a Jaw Crusher Production Line?

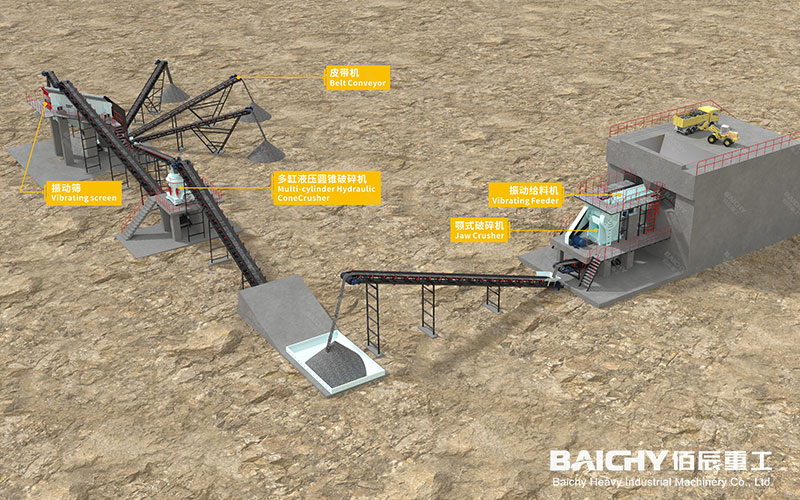

A jaw crusher production line is an automated, continuous production system that uses a jaw crusher as the core coarse crushing equipment and integrates auxiliary equipment such as feeding, conveying, screening, medium and fine crushing, and dust removal. Its task is to process raw materials of varying particle sizes (such as granite, basalt, and river pebbles) through multiple stages, ultimately producing aggregates of various specifications that meet different engineering requirements.

II. Core Members and Workflow of the Production Line

A typical jaw crusher production line is like a highly efficient industrial assembly line, where every link is crucial.

1. Feeding Stage: The "Cafeteria Auntie" of Uniform Feeding

• Equipment: Vibrating Feeder

• Function: Located at the very front of the production line, it is responsible for uniformly and continuously conveying material from the raw material hopper to the jaw crusher. It effectively prevents the jaw crusher's feed inlet from becoming blocked, ensuring the stable and efficient operation of the "coarse crushing pioneer," serving as the first guarantee for a smooth production process.

2. Coarse Crushing Stage: The "Pathfinder" Overcoming Difficulties

• Equipment: Jaw Crusher (Core Equipment)

• Function: This is the heart of the entire production line. It utilizes the squeezing action between the moving and stationary jaw plates to powerfully crush large pieces of material (typically hundreds or even thousands of millimeters) from the vibrating feeder. After being processed by its "iron teeth," the material is crushed to approximately tens to two hundred millimeters, preparing it for the next stage of crushing. Its powerful crushing force and high reliability make it the ideal choice for handling high-hardness materials.

3. Transfer and Screening Stage: The Smart "Dispatch Center"

• Equipment: Belt conveyor, circular vibrating screen

• Function:

◦ The belt conveyor is the "blood vessel" connecting the various equipment, responsible for the transfer of materials between different crushing stages.

◦ The circular vibrating screen is the key "quality inspector." It screens the material after coarse crushing. Material that meets the finished product particle size requirements is directly screened out and sent to the finished product stockpile. Larger, unqualified pieces are "returned" to the next stage crusher for further processing. This closed-loop design greatly improves production efficiency and yield.

4. Medium and Fine Crushing Stage: The Refined "Fine Processor"

• Equipment: Cone crusher, impact crusher, or vertical shaft impact crusher, etc.

• Function: Larger materials returning from the vibrating screen are sent to the medium and fine crushing equipment. For high-hardness, highly abrasive materials, cone crushers are typically chosen due to their layered crushing mechanism, resulting in high efficiency and good particle shape. For medium-hardness materials, impact crushers can be used, as their impact crushing principle produces even better cubic particle shapes. If simultaneous sand making is required, a vertical shaft impact crusher (sand making machine) is added.

5. Dust Removal and Noise Reduction: The "Environmental Guardian" of Green Production

• Equipment: Pulse bag filter, soundproof enclosure, etc.

• Function: Modern production lines must meet environmental protection requirements. Dust removal equipment effectively collects dust generated during crushing and screening, achieving clean production. Noise reduction measures reduce the impact on the surrounding environment, reflecting the company's social responsibility.

III. Key Advantages of Jaw Crusher Production Lines

• Strong Core, Stable and Reliable: The jaw crusher, known for its simple structure and durability, serves as the core of the coarse crushing process, ensuring a stable foundation for the production line, low failure rate, and continuous long-term operation.

• High Processing Capacity and Wide Application: Easily handles various high-hardness ores and construction waste, demonstrating strong adaptability.

• High degree of automation and low operating costs: The entire line can be automatically controlled, requiring minimal manpower, resulting in low energy consumption per unit product and significant long-term operational benefits.

• Controllable finished product quality and excellent particle shape: Through a combination of multi-stage crushing and screening, the particle size and shape of the finished material can be precisely controlled, meeting the stringent requirements of the high-end construction market for aggregate quality.

• Modular design and flexible layout: Modern production lines can adopt a modular design, allowing for flexible configuration based on site terrain and capacity requirements, shortening the construction cycle.

IV. Key Considerations for Designing an Efficient Production Line

Before investing in construction, scientific design is the cornerstone of success. The following points need to be considered:

1. Material characteristics: Hardness, moisture content, mud content, and maximum feed particle size are the primary basis for equipment selection.

2. Expected capacity: How many tons of material need to be processed per hour? This determines the size of all equipment models.

3. Finished product requirements: What types of finished products are required? Are there any special requirements for particle shape (e.g., cubic content)? This directly affects the configuration of medium and fine crushing equipment and screens.

4. Investment Budget and Site Conditions: The budget determines the brand and automation level of the equipment, while the site topography influences whether the production line layout is stepped or planar.

5. Environmental Regulations: Dust, noise, and wastewater treatment plans must be planned in advance to ensure compliance.

Jaw crusher production lines have long surpassed the simple aggregation of functions of a single piece of equipment; they are highly collaborative, intelligent, and efficient production systems. They are not only "profit engines" for mines and sand and gravel plants but also a vital force driving the development of national infrastructure towards intensification, large-scale production, and green practices.

Choosing a scientifically designed and rationally configured jaw crusher production line means choosing stable, efficient, and long-term returns. Before investing, be sure to consult a professional engineering team for detailed planning to maximize the value this powerful "hard rock nemesis" system creates for you.

We hope this comprehensive analysis helps you better understand jaw crusher production lines. If you have specific project needs, please feel free to contact us for professional technical consultation and solutions!