Among various crushing equipment, the roller crusher has always held an important place due to its unique advantages such as simple structure, low over-crushing rate, and uniform product particle size. This article will take you deeper into understanding this highly efficient "particle shaper," examining how it works and its outstanding features.

I. What is a Roller Crusher? Core Principles Revealed

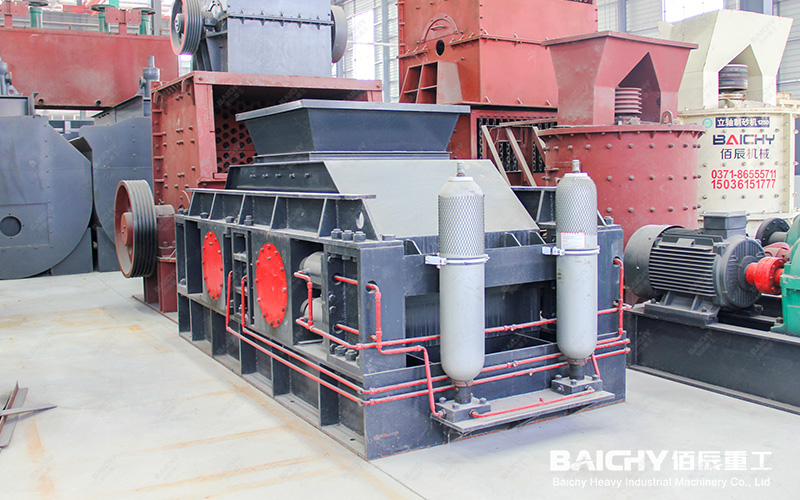

A roller crusher, as the name suggests, is a mechanical device that uses two counter-rotating rollers to squeeze and grind materials to achieve crushing. Its core working principle can be figuratively understood as a "stone mill."

Two rollers are the core working components; one is fixed, while the other is movable to adjust the gap between the two rollers (i.e., the discharge port size). Materials enter from above between the two rollers and are subjected to continuous squeezing and shearing forces. When the compressive strength of the material is less than the pressure applied by the rollers, it will break and eventually be discharged from the gap below, forming a finished product that meets the particle size requirements.

In short, the process is: Feeding → Biting → Squeezing/Grinding → Discharge.

II. Main Types: Meeting perse Crushing Needs

Based on material characteristics and output requirements, roller crushers have developed into several main types:

1. Double Roll Crusher: This is the most basic and common model. Both rollers rotate at the same speed, mainly used for medium and fine crushing of materials with a hardness of less than medium, producing a uniform particle size.

2. Four Roll Crusher: Essentially two double roll crushers connected in series. The upper pair of coarse rollers performs primary crushing, while the lower pair of fine rollers performs secondary crushing, achieving a higher crushing ratio and finer output particle size, suitable for applications with strict particle size requirements.

3. Toothed Roll Crusher: The roller surface is not smooth but equipped with toothed crowns or crushing plates. These "teeth" generate splitting and impact effects, making it particularly suitable for crushing sticky materials or materials containing a lot of fiber, such as coal, coke, and limestone, effectively preventing clogging.

4. Double Roll Crusher (Smooth Roller Surface): Mainly used for fine crushing operations requiring low powder content and good particle shape, such as sand making and glass raw material preparation.

III. Core Advantages: Why Choose a Roller Crusher?

Compared to other types of crushers (such as jaw crushers, impact crushers, and cone crushers), roller crushers possess unique and irreplaceable advantages:

• Low over-crushing rate and uniform product particle size: This is its most prominent advantage. Due to controlled compression crushing, material is immediately discharged once it is crushed to a size smaller than the roller gap, avoiding repeated impact and grinding within the crushing chamber. Therefore, very little powder (over-crushed material) is produced, resulting in a high proportion of cubical finished products with a concentrated particle size distribution.

• Simple structure and convenient maintenance: The overall structure is compact with relatively few parts, making daily inspection and replacement of wear parts (such as roller skin) very convenient, significantly reducing later maintenance costs and time.

• Stable operation, low noise and dust: Compared to impact crushers, compression crushing operates more smoothly, generating less noise and vibration. With sealing devices and dust collection systems, dust leakage can be effectively controlled, better meeting environmental protection requirements.

• Highly adjustable, allowing flexible control of discharge particle size: The maximum discharge particle size can be precisely controlled by simply adjusting the gap between the two rollers, offering flexible operation and strong adaptability.

• Suitable for sticky and wet materials: Especially toothed roller crushers, their "pulling" and "shearing" action effectively handles materials with slightly high moisture content or a certain degree of stickiness, exhibiting strong anti-clogging capabilities.

IV. Wide Range of Applications: Where Does It Shine?

Roller crushers have a very wide range of applications, covering almost all industrial fields that require reducing the particle size of lumpy materials:

• Mining Industry: Used for crushing coal, limestone, iron ore, potash, phosphate rock, etc.

• Building Materials Industry: Used for crushing cement raw materials and clinker, sand making, and the preparation of ceramic and glass raw materials.

• Chemical Industry: Used for crushing fertilizer raw materials and various chemical minerals.

• Metallurgical Industry: Used for crushing sintered ore and coke.

• Environmental Protection Industry: Used in the recycling of construction waste for crushing concrete and bricks, effectively maintaining the particle shape of recycled aggregates.

V. How to Select and Maintain? A Practical Guide for Users

Selection Points:

1. Material Characteristics: First, analyze the hardness, moisture content, viscosity, feed particle size, and required output particle size of the material to be crushed. This is the fundamental basis for selecting the type of equipment (e.g., smooth roller or toothed roller) and model.

2. Production Capacity: Determine the equipment specifications based on your production needs (tons/hour).

3. Roller Material: For high-hardness or highly corrosive materials, select rollers made of wear-resistant materials such as high-manganese steel or high-chromium cast iron to extend service life.

4. Safety Devices: Check whether the equipment is equipped with an overload protection device (such as a hydraulic or spring safety device) to prevent serious damage to the equipment from uncrushable objects such as iron.

Maintenance Recommendations:

• Regular Lubrication: Strictly follow the instruction manual to lubricate rotating parts such as bearings. This is crucial for ensuring the long-term stable operation of the equipment.

• Check for wear: Regularly check the wear of the roller skins. When wear affects the output particle size, adjust the roller gap or replace the roller skins promptly. For double rollers, ensure that the wear of both rollers is synchronized; otherwise, the crushing effect will be affected.

• Tighten bolts: Regularly check whether the bolts at all connection points are loose.

• Clean equipment: After shutdown, promptly clean the accumulated material and dust from the equipment surface.

While the roller crusher may not be the most "high-end" equipment in the crushing field, its simplicity, efficiency, reliability, and precise control over product particle shape make it the most cost-effective choice in specific application scenarios. Whether as the main crushing equipment on a production line or as an auxiliary device for fine shaping, this quietly working "particle shaper" continues to contribute a significant force to the development of modern industry.